Oil slick recovery device and oil slick recovery equipment

A technology of oil slick recovery and oil-water separation device, which is applied in the direction of grease/oily substance/suspton removal device, liquid separation, chemical instruments and methods, etc., can solve the problems of increased cost of oil slick recovery, poor recovery efficiency, etc., to achieve The effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical content, compositional features, achieved goals and effects of the present invention will be described in detail below in conjunction with the embodiments of the present invention.

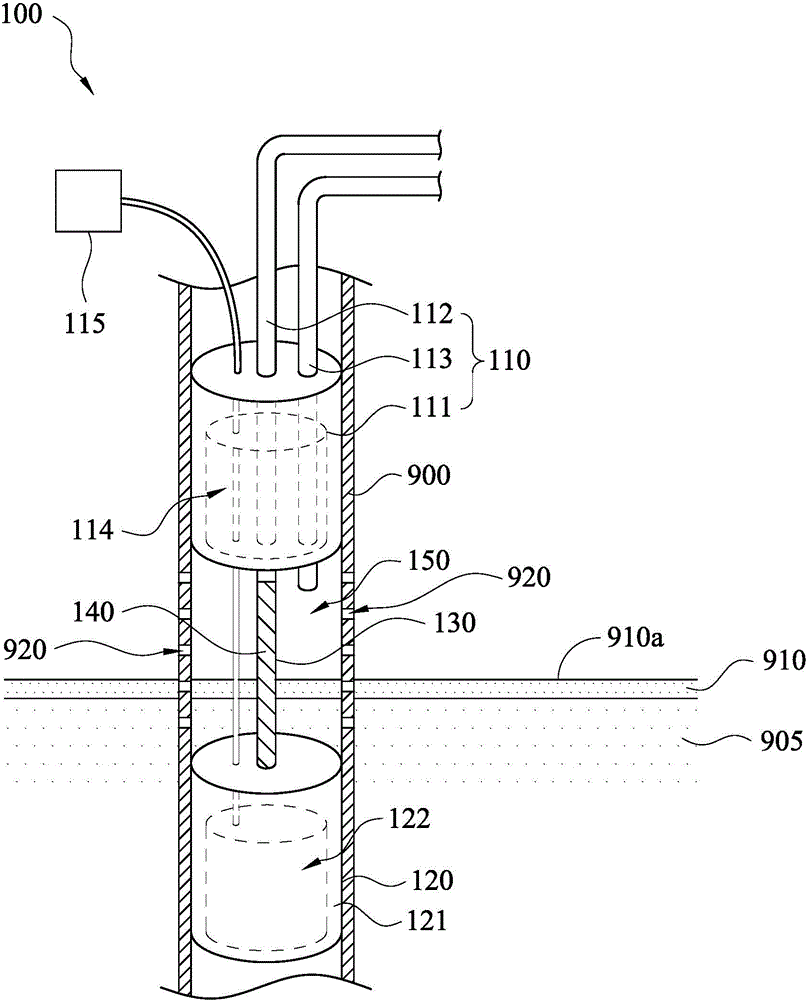

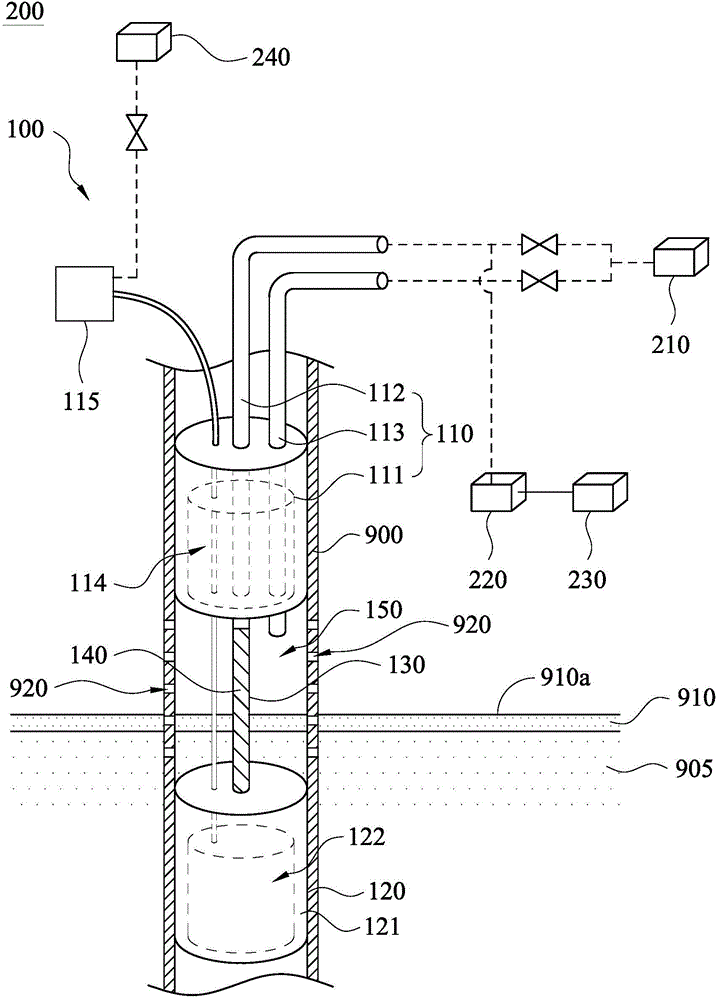

[0021] Please refer to figure 1 , figure 1 It is a schematic cross-sectional view of an oil floating recovery device 100 according to an embodiment of the present invention. Oil slick recovery device 100 may be adapted to draw fluid 905 containing slick oil 910 within recovery well 900 . In one example, the recovery well 900 may be placed after the area of the subterranean aquifer contaminated by the oil slick 910 has been identified. In an exemplary example, the depth of the recovery well 900 needs to be set deep into the underground aquifer, so that the groundwater polluted by the floating oil 910 in the underground aquifer flows into the recovery well 900 . In another exemplary example, a well screen 920 may be provided on the sidewall of the recovery well 900 to allow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com