Oil-gas separating disc

A separation disc, oil and gas technology, used in separation methods, dispersed particle separation, oil fume removal, etc., can solve the problems of easy falling off, intercepting oil mist and unable to form sufficient adhesion, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

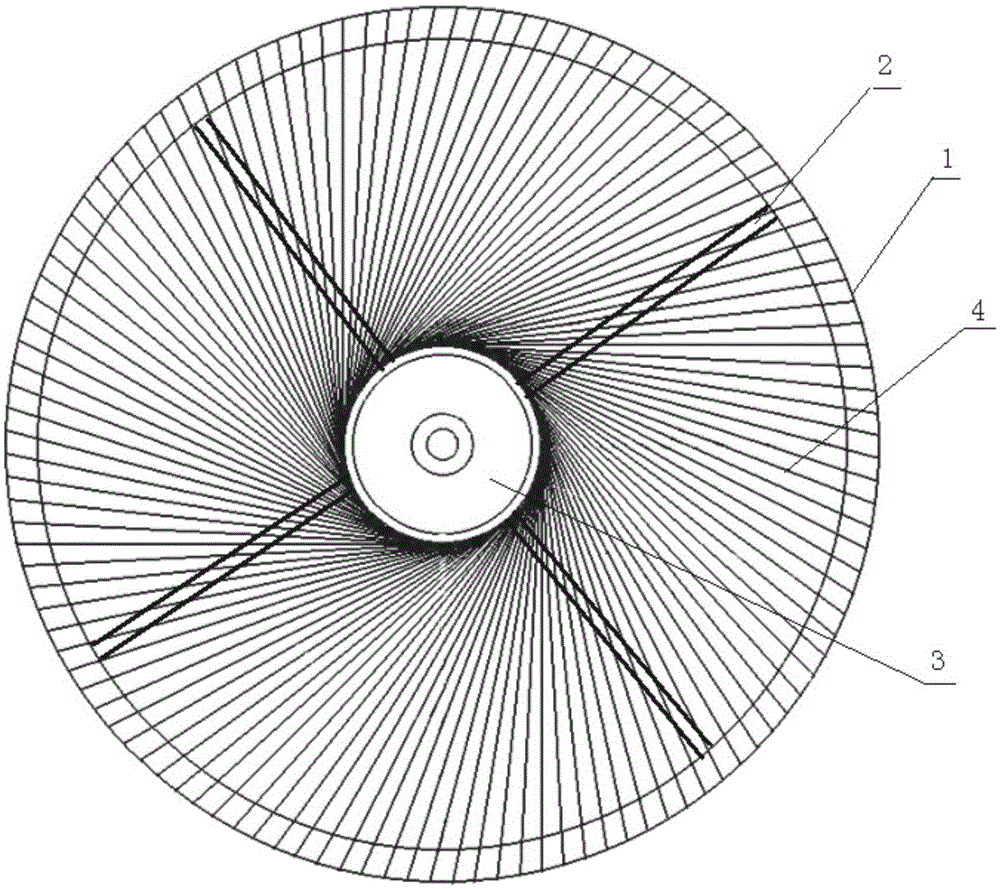

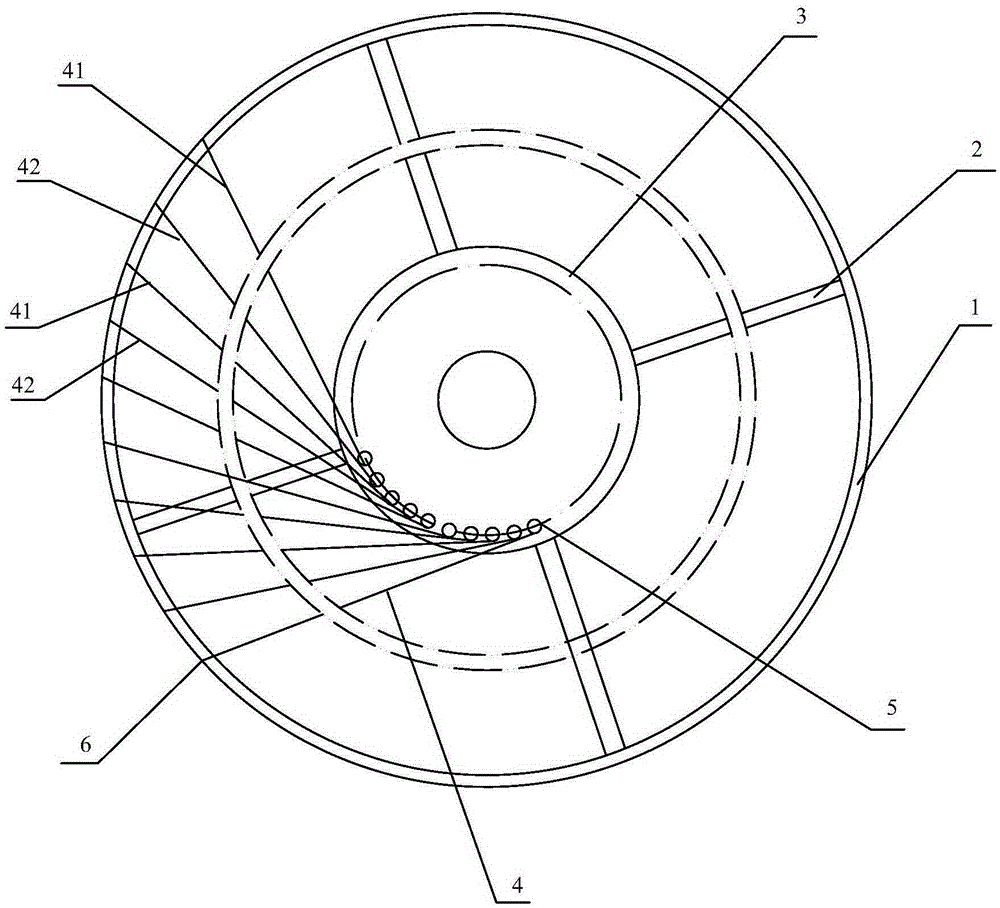

[0027] Embodiment 1. An oil-gas separation disc, comprising an outer rim 1 and an inner rim 3, the outer rim 1 and the inner rim 3 are connected by several uniformly and symmetrically arranged radial support ribs 2; the radial support ribs 2 The number is generally 4 to 8.

[0028] In the annular area between the outer rim 1 and the inner rim 3, two upper and lower layers of tangential radial filter screens 4 are arranged.

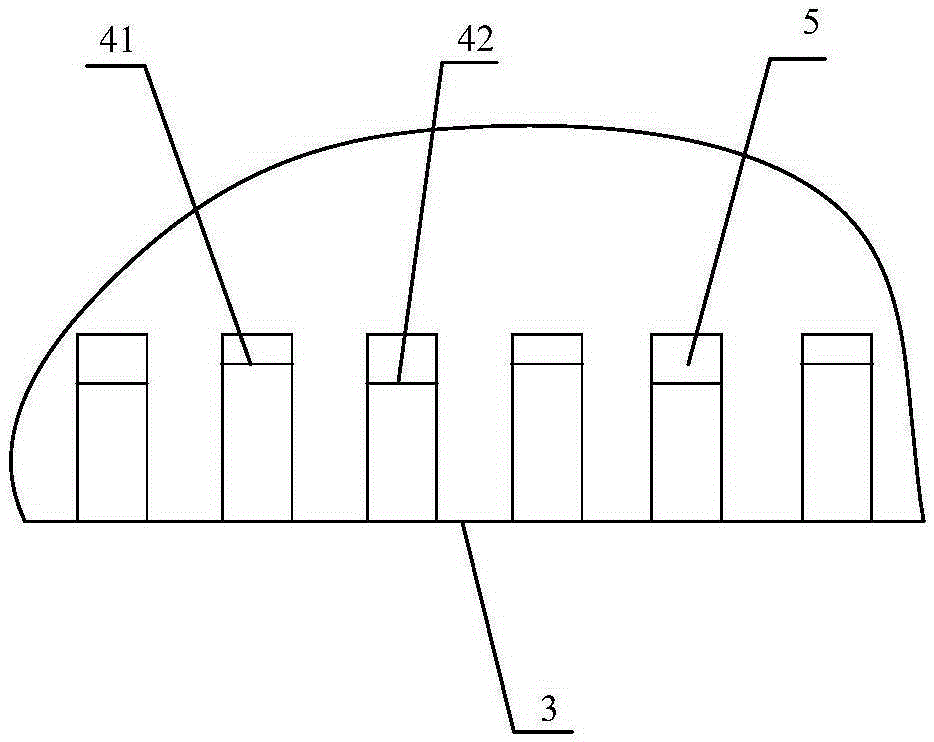

[0029] The structure of the tangent radial filter screen 4 of each layer is as follows: each mesh line on the tangent radial filter mesh 4 is the tangent line of the inner rim 3; ; That is, the combination of wires on the tangential radial filter screen 4 forms the tangential direction of the inner rim 3 .

[0030] A number of fixed parts—cylindrical bosses 5 are evenly arranged along the outer circumference of the inner rim 3, and positioning parts corresponding to the cylindrical bosses 5 are arranged on the outer rim 1—grooves 6, tangential radial filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com