A swirl plate type SCR denitrification tower and denitrification method thereof

A technology of denitrification tower and swirl plate, which is applied in the field of flue gas denitrification, can solve problems such as easy ash accumulation, ammonia escape, and catalyst failure, and achieve the effects of reducing dosage, increasing specific surface area, and uniform flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

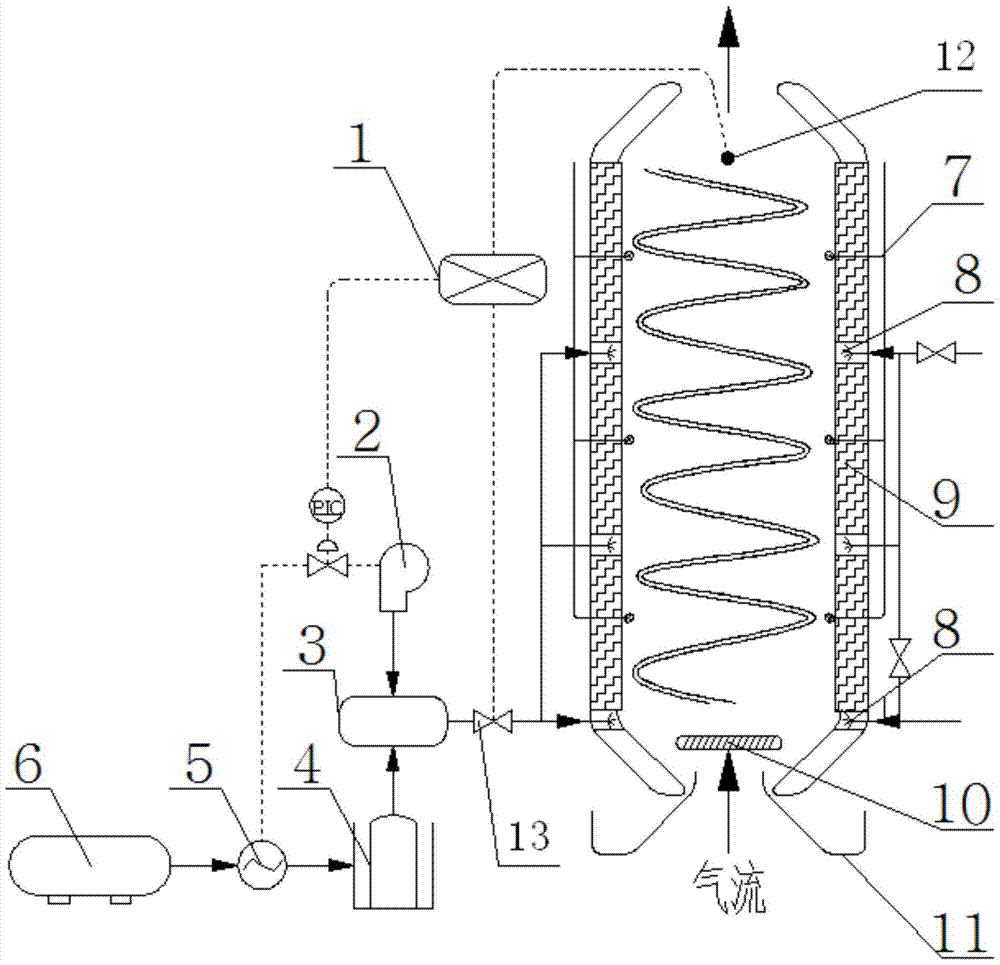

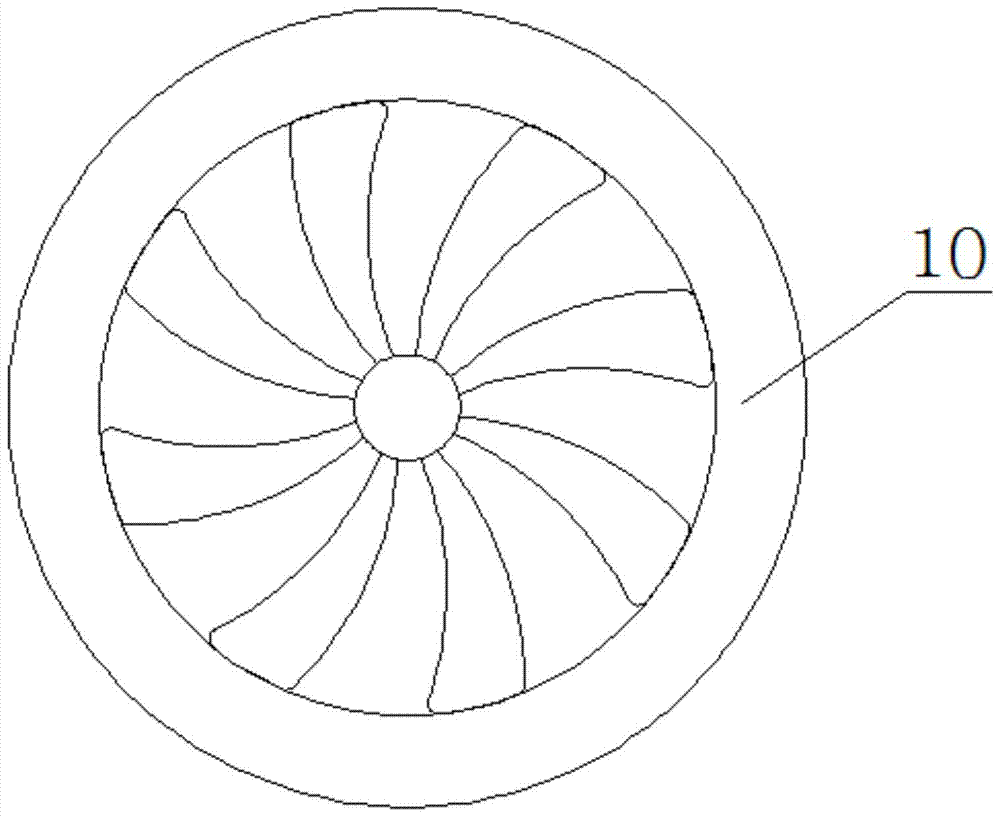

[0027] Such as figure 1 , 2 shown. The invention discloses a swirling plate type SCR denitrification tower, which comprises a denitrification tower body and a corrugated plate catalyst layer 9 arranged along the inner circumferential surface of the denitrification tower body; the corrugated plate catalyst layer 9 constitutes a flue gas channel; On the circumferential surface of the denitrification tower, there are multiple swirl atomizing nozzles 8 sprayed along the tangential direction from bottom to top; When the ammonia gas meets, because the ammonia gas swirls along the tangential direction, the flue gas and the ammonia gas are entrained and mixed with each other, and spiral up along the inner circumference of the flue gas channel in a tangential circle; the swirl The ammonia gas and the flue gas ejected from the flow move together, which strengthens the mixing of the flue gas and the reducing agent, and makes the entire flow field fully reach a turbulent flow state, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com