A temperature-adjusting and humidity-regulating composite material with photocatalytic performance and its preparation method

A photocatalytic material, temperature and humidity regulation technology, applied in the direction of heat exchange materials, chemical instruments and methods, separation methods, etc., can solve the problems of indoor environmental secondary pollution, microbial growth, large energy consumption, etc., to reduce the cost of building Energy consumption, enhanced humidity control performance, and the effect of promoting photocatalytic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

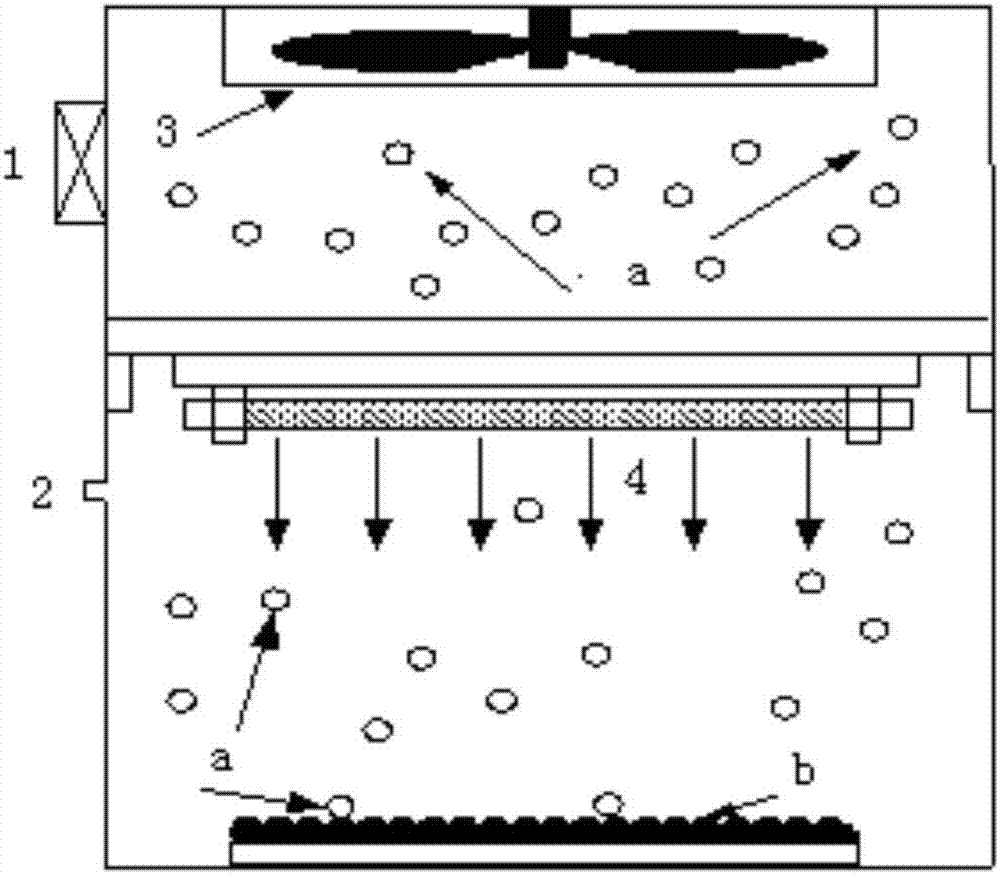

Image

Examples

Embodiment 1

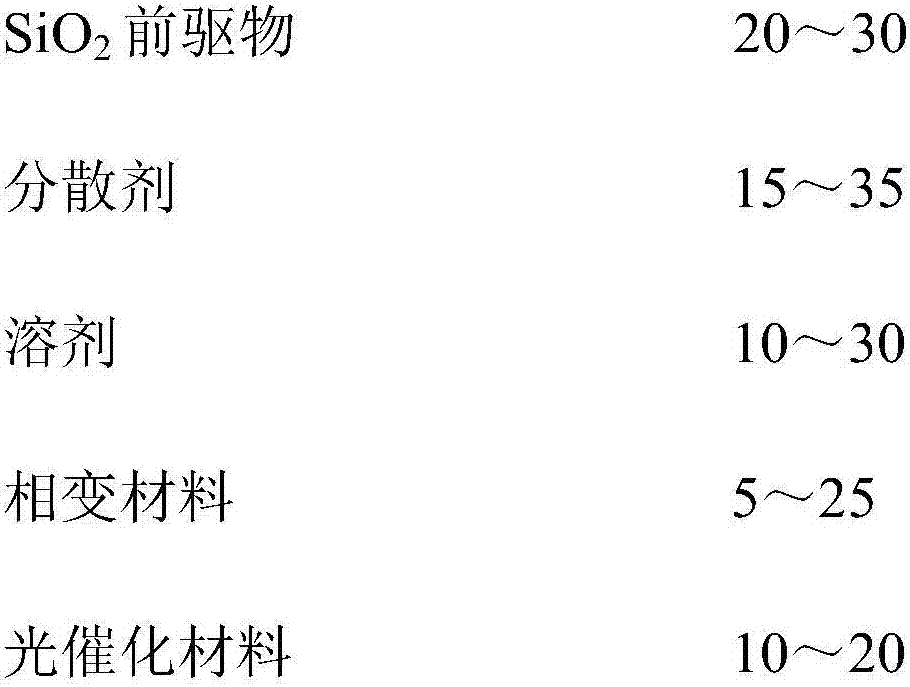

[0028] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0029]

[0030] (1) Preparation of palmitic alcohol-palmitic acid-lauric acid phase change material: Put the mixture of palmitic alcohol, palmitic acid and lauric acid in a container, and use a constant temperature magnetic stirrer to mix the mixture at 2000r / min and 65°C in a water bath. After dissolving and stirring for 4 hours, a palmitic alcohol-palmitic acid-lauric acid phase change material was obtained. The mass percent of palmityl alcohol, palmitic acid and lauric acid in the palmitic alcohol-palmitic acid-lauric acid phase change material is 20:30:50.

[0031] (2) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the beaker in sequence according to the above formula ratio, stir with a constant temperature magnetic stirrer at 1200r / min and 65°C water bath for 15min, and mix the obtained Stir the mixture at...

Embodiment 2

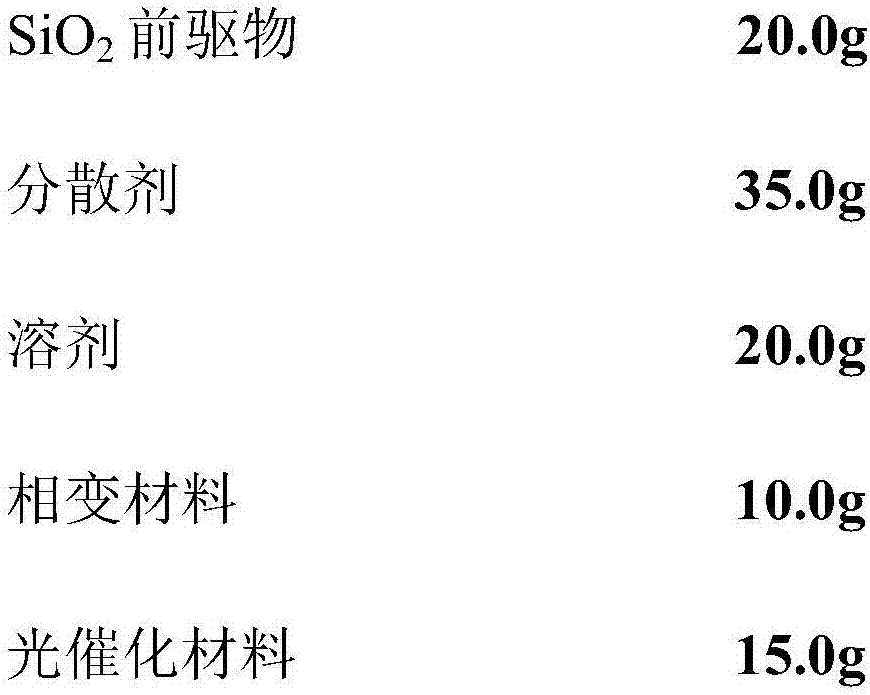

[0035] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0036]

[0037] (1) Preparation of palmitic alcohol-palmitic acid-lauric acid phase change material: Put the mixture of palmitic alcohol, palmitic acid and lauric acid in a container, and use a constant temperature magnetic stirrer to mix the mixture at 2000r / min and 65°C in a water bath. After dissolving and stirring for 4 hours, a palmitic alcohol-palmitic acid-lauric acid phase change material was obtained. The mass percent of palmityl alcohol, palmitic acid and lauric acid in the palmityl alcohol-palmitic acid-lauric acid phase change material is 40:20:40.

[0038] (2) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the beaker in sequence according to the above formula ratio, stir with a constant temperature magnetic stirrer at 1200r / min and 65°C water bath for 15min, and mix the obtained Stir the mixture at...

Embodiment 3

[0042] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0043]

[0044] (1) Preparation of palmitic alcohol-palmitic acid-lauric acid phase change material: Put the mixture of palmitic alcohol, palmitic acid and lauric acid in a container, and use a constant temperature magnetic stirrer to mix the mixture at 2000r / min and 65°C in a water bath. After dissolving and stirring for 4 hours, a palmitic alcohol-palmitic acid-lauric acid phase change material was obtained. The mass percent of palmityl alcohol, palmitic acid and lauric acid in the palmitic alcohol-palmitic acid-lauric acid phase change material is 30:30:40.

[0045] (2) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the beaker in sequence according to the above formula ratio, stir with a constant temperature magnetic stirrer at 1200r / min and 65°C water bath for 15min, and mix the obtained Stir the mixture at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com