A photocatalytic composite material with temperature and humidity regulation performance and preparation method thereof

A technology of photocatalytic materials and composite materials, applied in the field of photocatalytic composite materials and their preparation, can solve problems such as indoor environmental secondary pollution, microbial growth, difficult pipeline cleaning, etc., achieve enhanced humidity control performance, improve market competitiveness, Realize the effect of humidity control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

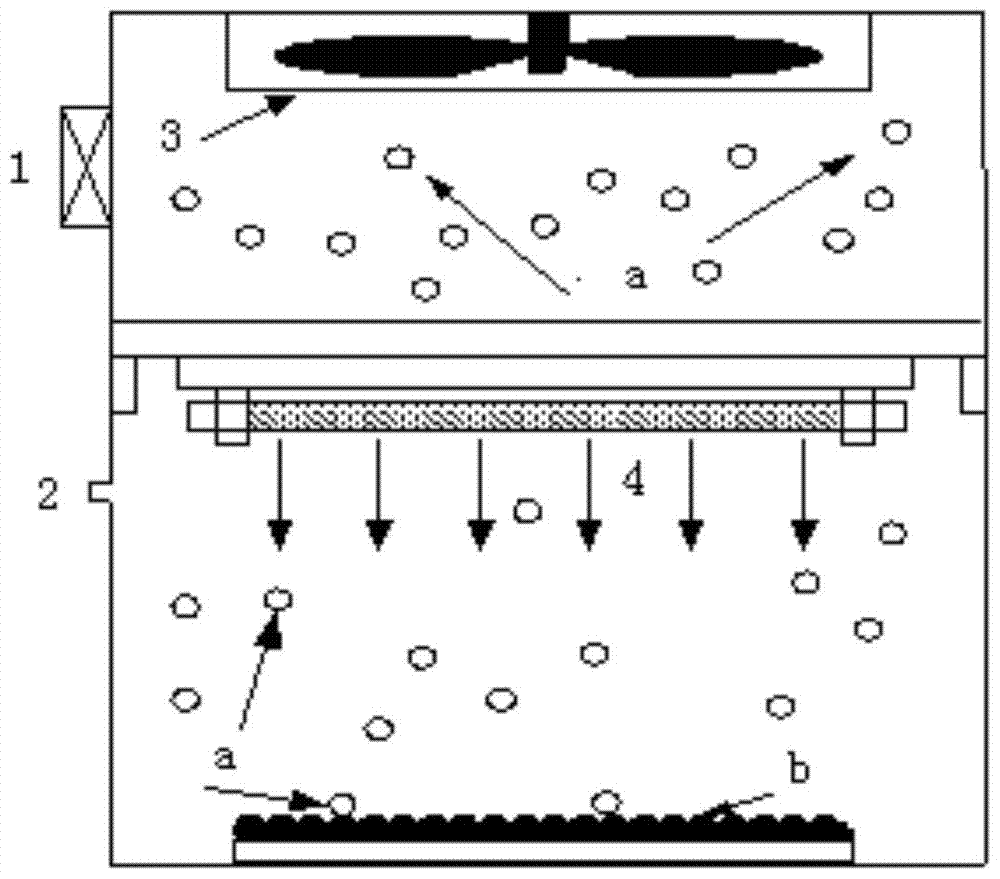

Method used

Image

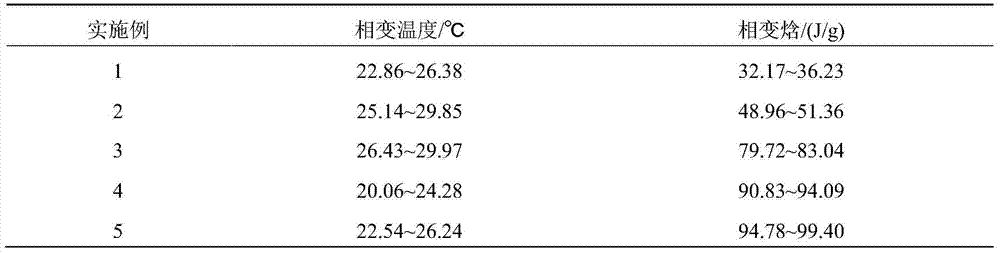

Examples

Embodiment 1

[0028] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0029] Phase change material 10.0g

[0030] Photocatalytic material 90.0g

[0031] (1) Put the mixture of palmitic alcohol, palmitic acid and lauric acid into a container, and use a constant temperature magnetic stirrer to dissolve the mixture at 2000r / min and 65°C in a water bath and stir for 4 hours to obtain palmitic alcohol-palmitic acid-lauric acid phase change material. The mass fraction ratio of palmityl alcohol, palmitic acid and lauric acid in the palmitic alcohol-palmitic acid-lauric acid phase change material is 20%:30%:50%.

[0032](2) According to the volume ratio of tetrabutyl titanate and absolute ethanol in the ratio of 2:5, use a constant temperature magnetic stirrer to stir at 1200r / min for 30min to obtain a uniform transparent solution, and then dissolve europium nitrate and cerium nitrate Slowly add dilute hydrochlor...

Embodiment 2

[0035] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0036] Phase change material 15.0g

[0037] Photocatalytic material 85.0g

[0038] (1) Put the mixture of palmitic alcohol, palmitic acid and lauric acid into a container, and use a constant temperature magnetic stirrer to dissolve the mixture at 2000r / min and 65°C in a water bath and stir for 4 hours to obtain palmitic alcohol-palmitic acid-lauric acid phase change material. The mass fraction ratio of palmityl alcohol, palmitic acid and lauric acid in the palmityl alcohol-palmitic acid-lauric acid phase change material is 40%:20%:40%.

[0039] (2) According to the volume ratio of tetrabutyl titanate and absolute ethanol in the ratio of 2:5, use a constant temperature magnetic stirrer to stir at 1200r / min for 30min to obtain a uniform transparent solution, and then dissolve europium nitrate and cerium nitrate Slowly add dilute hydrochlo...

Embodiment 3

[0042] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0043] Phase change material 20.0g

[0044] Photocatalytic material 80.0g

[0045] (1) Put the mixture of palmitic alcohol, palmitic acid and lauric acid into a container, and use a constant temperature magnetic stirrer to dissolve the mixture at 2000r / min and 65°C in a water bath and stir for 4 hours to obtain palmitic alcohol-palmitic acid-lauric acid phase change material. The mass fraction ratio of palmityl alcohol, palmitic acid and lauric acid in the palmitic alcohol-palmitic acid-lauric acid phase change material is 30%:30%:40%.

[0046] (2) According to the volume ratio of tetrabutyl titanate and absolute ethanol in the ratio of 2:5, use a constant temperature magnetic stirrer to stir at 1200r / min for 30min to obtain a uniform transparent solution, and then dissolve europium nitrate and cerium nitrate Slowly add dilute hydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com