Wafer gumming machine and gumming method

A technology of gluing machine and wafer, which is applied in the direction of coating, device for coating liquid on the surface, electrical components, etc., to achieve the effect of widening the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following further description of the specific embodiments and implementations in conjunction with the accompanying drawings can help those skilled in the art to fully and effectively understand the essential content of the present invention, so as to achieve the repeated realization of the technical solution under the condition of knowing the patent content of the present invention Degree.

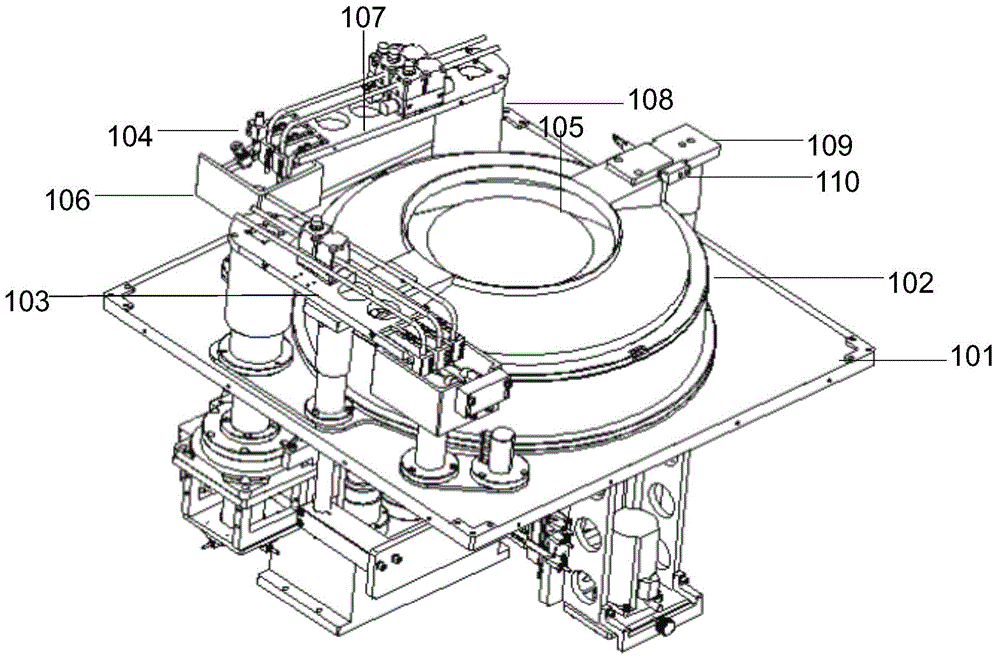

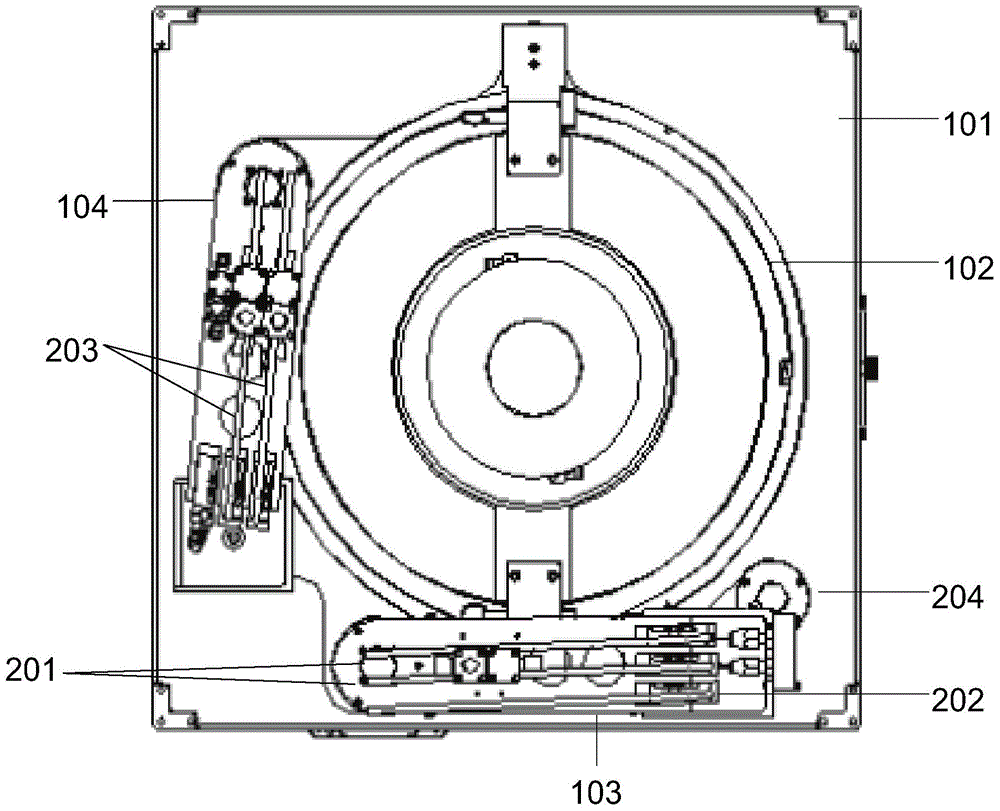

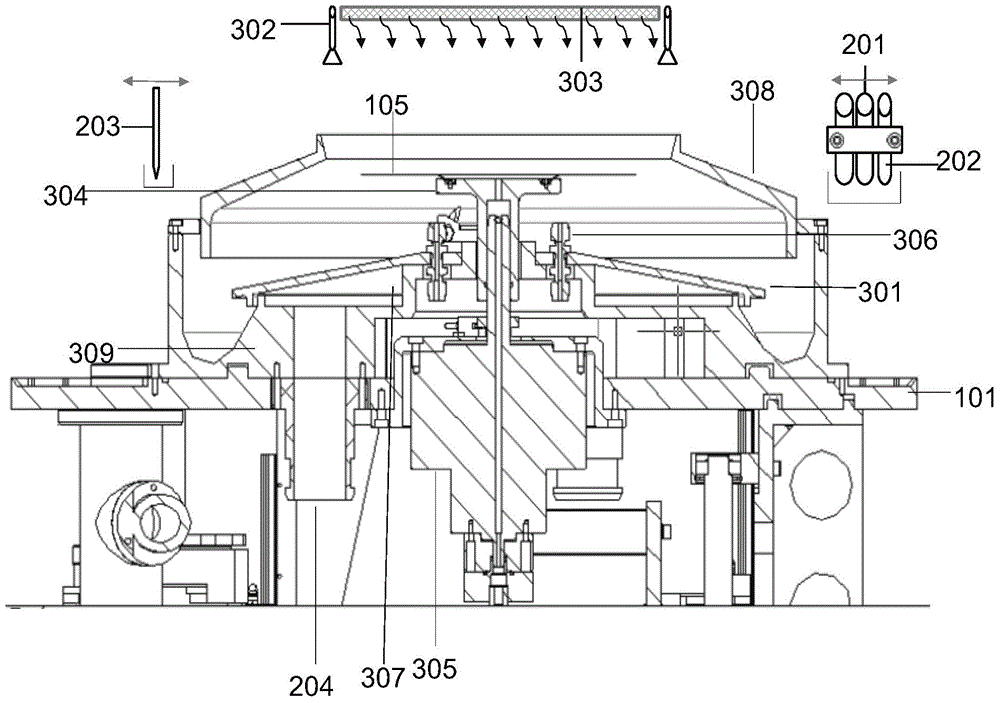

[0041] See attached Figure 1-3 , you will know the structural information of the wafer gluing machine of the present invention and understand the connection relationship between the various components.

[0042] in, figure 1 The overall display of the wafer gluing machine is made, figure 2 and image 3 The structural features of the wafer gluing machine are given in two different dimensions from the top and the side, respectively.

[0043] Specifically, the wafer gluing machine has a process chamber 100, the process chamber 100 constitutes a closed process space, and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com