Trepanned transverse bar positioning device for welding trepanned steel bar mesh on mesh welding machine

A technology of steel mesh and positioning device, which is applied to welding equipment, welding/welding/cutting items, resistance welding equipment, etc., can solve the problems of material waste, high cost, low production efficiency, etc., and achieve convenient maintenance and low cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

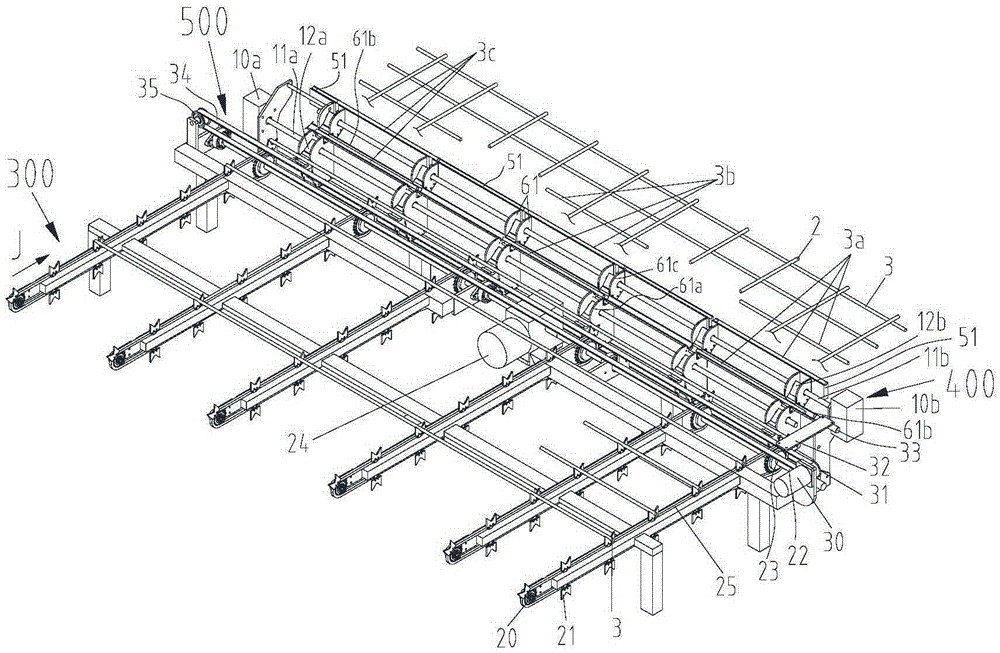

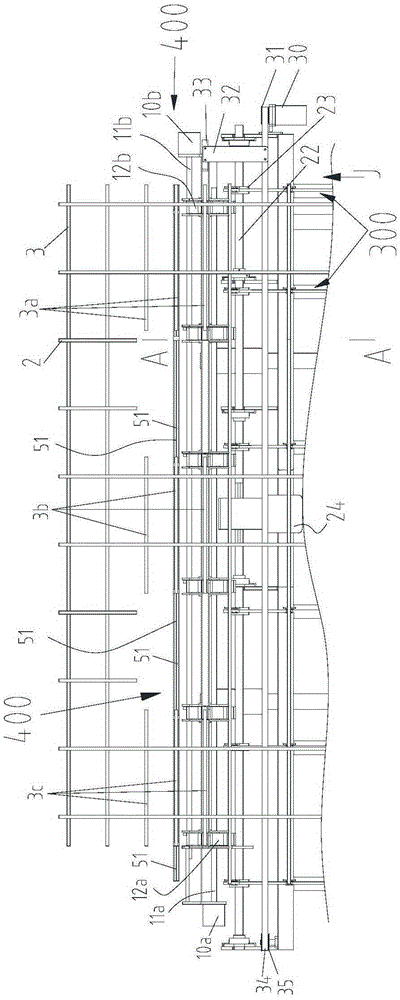

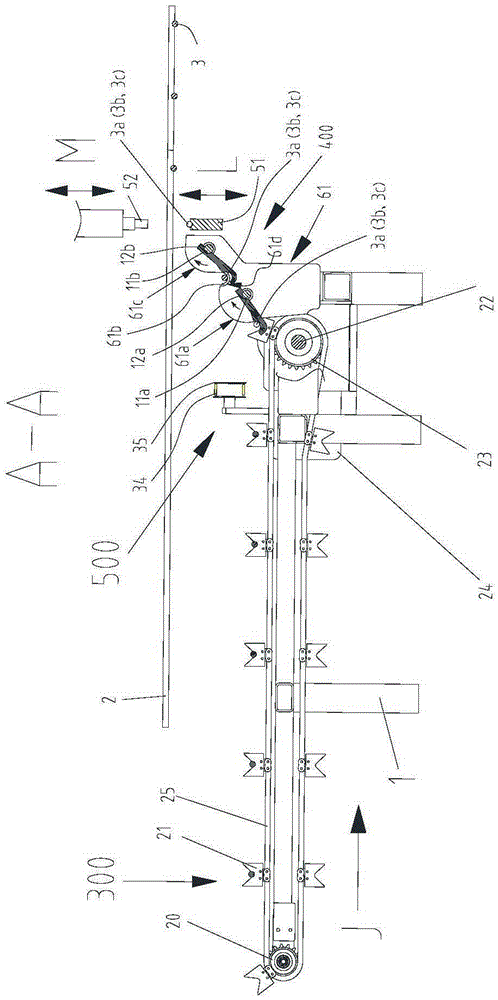

[0028] The invention provides a perforated horizontal bar positioning device for welding perforated steel mesh sheets on a welded mesh machine. The perforated horizontal bar positioning device is arranged on the frame 1 at the lower part of the longitudinal bar 2, and its structure includes: a plurality of conveyors arranged at intervals Mechanism 300, transfer mechanism 400, transfer mechanism 500 with transverse rib push plate 33, lower welding electrode 51 and upper welding electrode 52 that can move up and down; the transfer mechanism 400 is located on the frame between the conveying mechanism 300 and the lower welding electrode 51 1 on.

[0029] The first perforated transverse rib 3a, the second perforated transverse rib 3b and the third perforated transverse rib 3c transported by the conveying mechanism 300 are transferred to the chute 61b provided...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap