Method for preparing explosive cladding metal bar

A technology of composite metal and metal materials, which is applied in the field of preparation of explosive composite metal rods, can solve the problems of blasting shock waves and noise, increase the production cost of blasting composite materials, limit the production scale of blasting composite materials, etc., and achieve the solution of shock waves and noise , Improve energy utilization rate, economic benefit and social benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] In order to further describe the present invention, the preparation method of an explosive composite metal rod of the present invention will be further described below with reference to the accompanying drawings and embodiments.

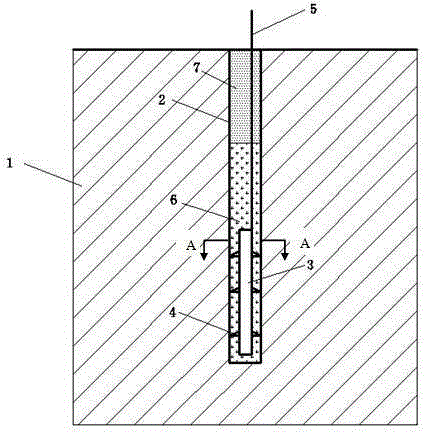

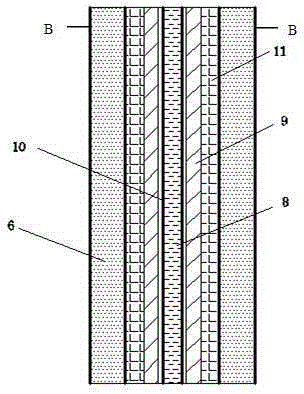

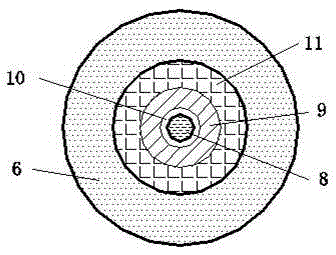

[0028] by figure 1 The blast hole structure layout diagram of the preparation method of the explosive composite metal rod of the present invention is shown and combined figure 2 , image 3 It can be seen that the preparation method of an explosive composite metal rod of the present invention adopts the following processes and steps:

[0029] 1) The test mine step height is 12m. In the waterless pre-blasted rock mass 1 of the open-pit mine step, the plum-shaped holes are arranged in accordance with the designed blasting hole network parameters to form a water-free and dry vertical blast hole 2; the blast hole 2 has a diameter of 200mm, The hole depth is 15m, of which the super deep is 3m.

[0030] 2) Clean up the blast hole 2. After the blast hole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap