High power locomotive transmission device

A kind of transmission device, high-power technology, applied in the direction of the transmission device driven by electric motor, etc., can solve the problems of limited axial load capacity of ball bearing, complex structure, inability to use helical angle helical gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

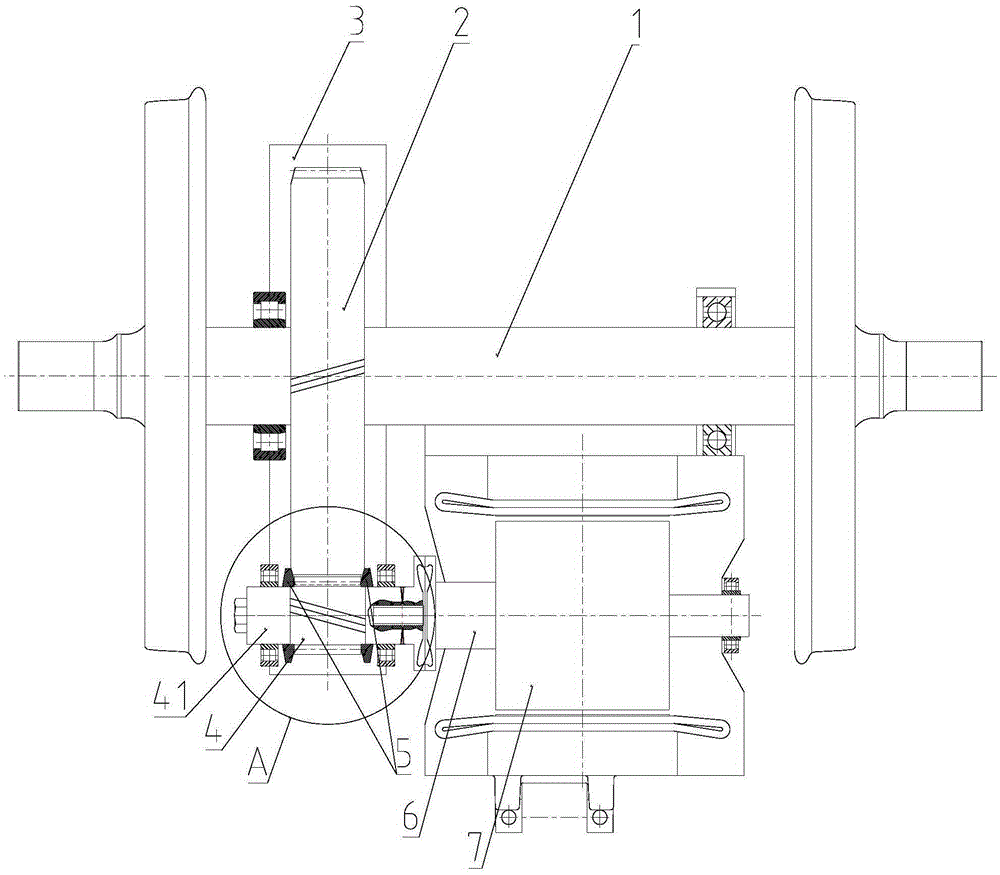

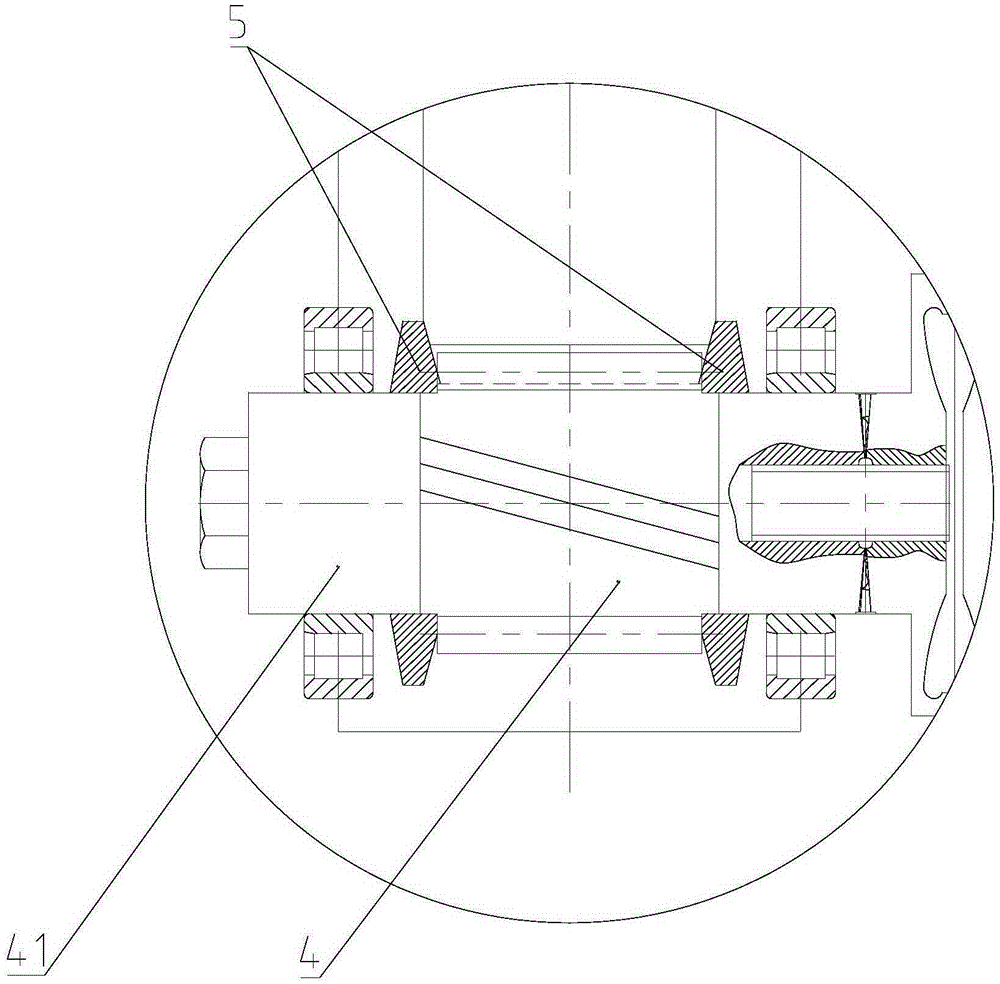

[0020] The core of the present invention is to provide a high-power locomotive transmission device, which can withstand greater axial force, so helical gears with larger helix angles can be used to improve the load-carrying capacity and running stability of the transmission device.

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the high-power locomotive transmission device provided by the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

[0022] Such as figure 1 Shown is a structural diagram of a high-power locomotive transmission designed for the implementation of the present invention. The device includes a large gear 2 set on the axle 1, a gear box 3 installed on the outside of the large gear 2 and other components. The large gear 2 is fixed in interference connection with the axle 1, and the wheel is driven by the axle 1. The gear box 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com