A rotary bag dumping device

A technology of bag dumping and rotating motor, which is applied in packaging, transportation and packaging, unsealing of packaging objects, etc., can solve the problems of low material unloading efficiency and inefficient use of ton bags, so as to improve material unloading efficiency, improve utilization rate, Avoid single-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiment of the present application provides a rotating bag-reversing device to solve the problem of one-time low-efficiency use of tons of bags in the process of material shipment through tons of bags in the prior art, and at the same time solve the technical problem of low material unloading efficiency; It has achieved the technical effect of improving the utilization rate of tons of bags, reducing waste, and improving the efficiency of material unloading.

[0025] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

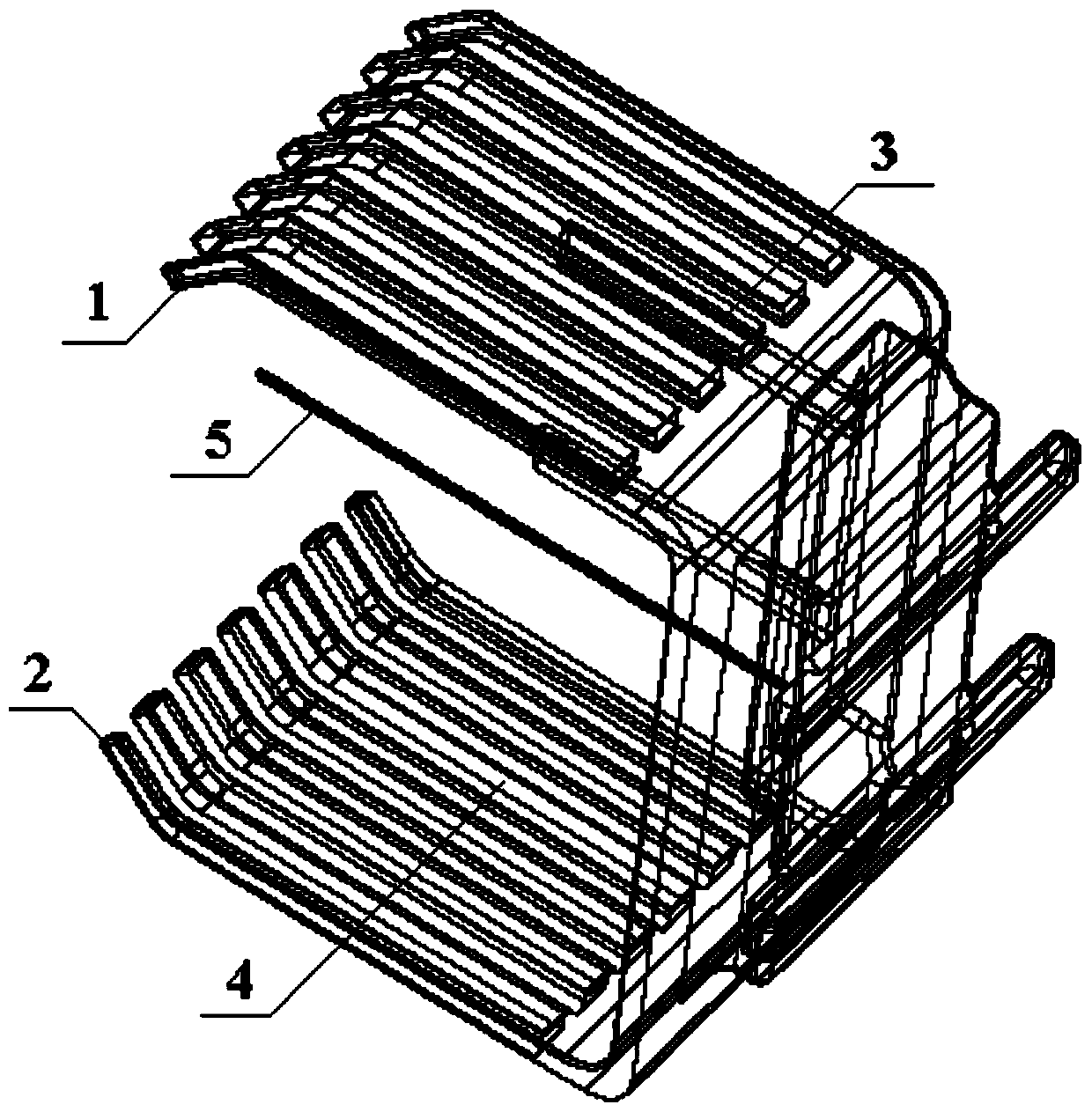

[0026] A rotary bag dumping device, comprising: a mechanical gripper, a rotary motor, a base, a hydraulic power unit, and an industrial computer;

[0027] Both the mechanical gripper and the rotating motor are fixed on the base, connected through a transmission shaft, and drive the mechanical gripper to deflect within a certain angle range;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com