A temperature-memory color-changing insulating material and insulating sleeve

A technology of insulating material and temperature memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

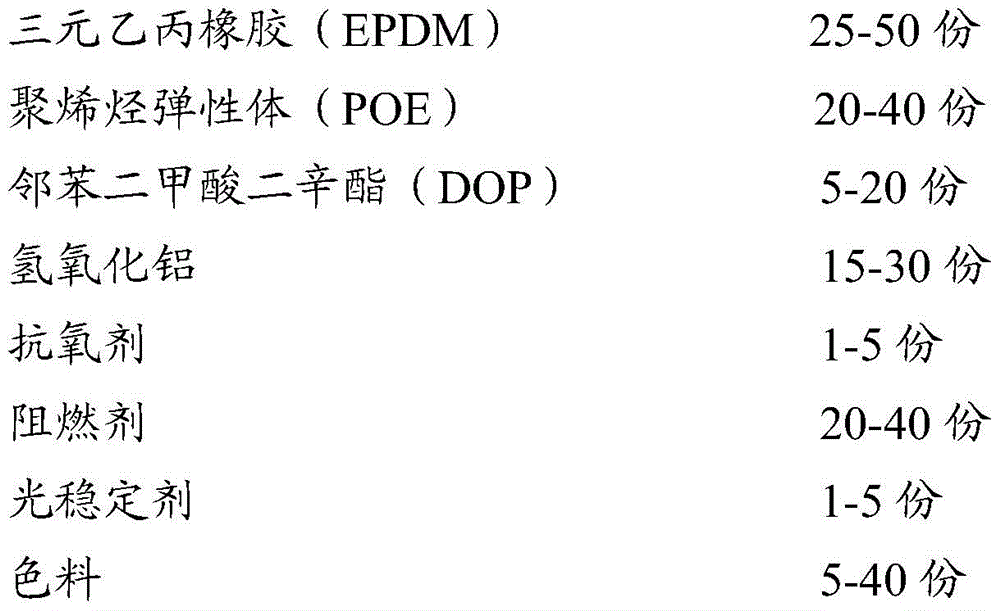

Embodiment 1

[0027]

[0028]

[0029] Prepare the insulating sleeve with the above components as follows: first mix the components together, then use a twin-screw extruder to plasticize, melt, and extrude granules, and the extrusion temperature is 180°C; use a single-screw extruder The machine extrudes the obtained particles into a round tube with the temperature controlled at 150°C; the obtained round tube is processed by irradiation and then heated and expanded with the temperature controlled at 130°C. Among them, the color materials in the components can use various color toners and color masterbatches (the same below).

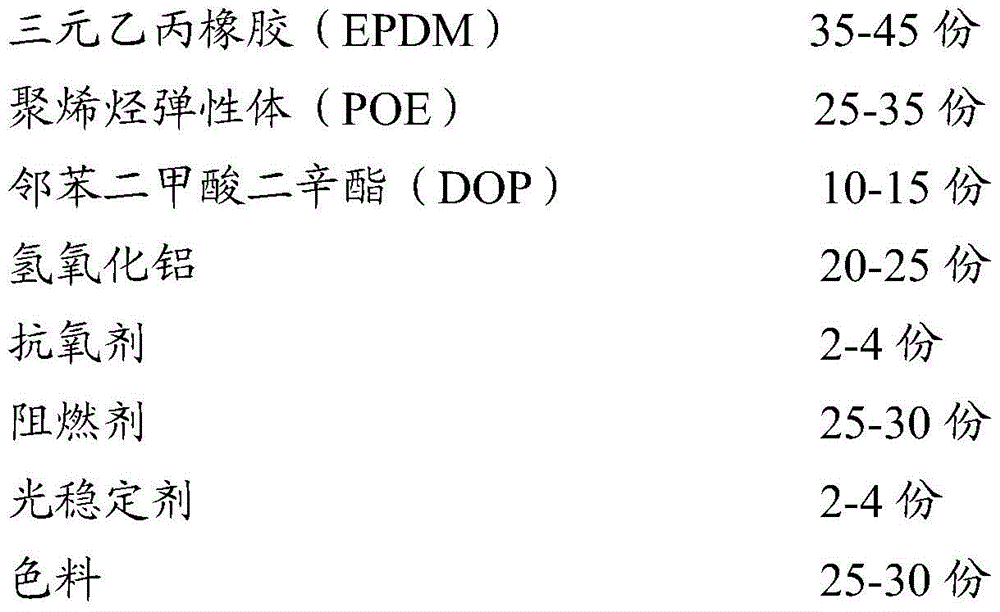

Embodiment 2

[0031]

[0032] Prepare the insulating sleeve with the above components as follows: first mix the components together, then use a twin-screw extruder to plasticize, melt, and extrude granules, and the extrusion temperature is 180°C; use a single-screw extruder The obtained pellets are extruded into a round tube by a machine, and the temperature is controlled at 170°C; the obtained round tube is subjected to irradiation processing, and then heated and expanded, and the temperature is controlled at 150°C.

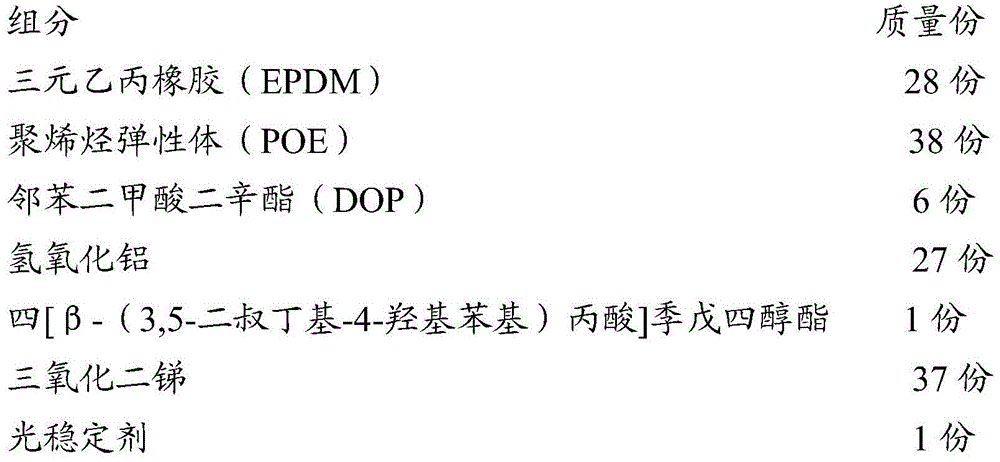

Embodiment 3

[0034] The types and mass parts of the components and the steps of preparing the insulating tube are the same as those in Example 2, except that the temperature is controlled at 160°C during the process of extruding the obtained pellets into a round tube with a single-screw extruder; during the heating and expansion process, the temperature is controlled at 140°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com