A kind of preparation method of flocculation precipitant for the treatment of regenerated lead wastewater

A wastewater treatment and precipitant technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as single function, affecting sewage treatment effect, complicated operation process, etc. , to achieve the effect of less dosage, overcoming low floc strength and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

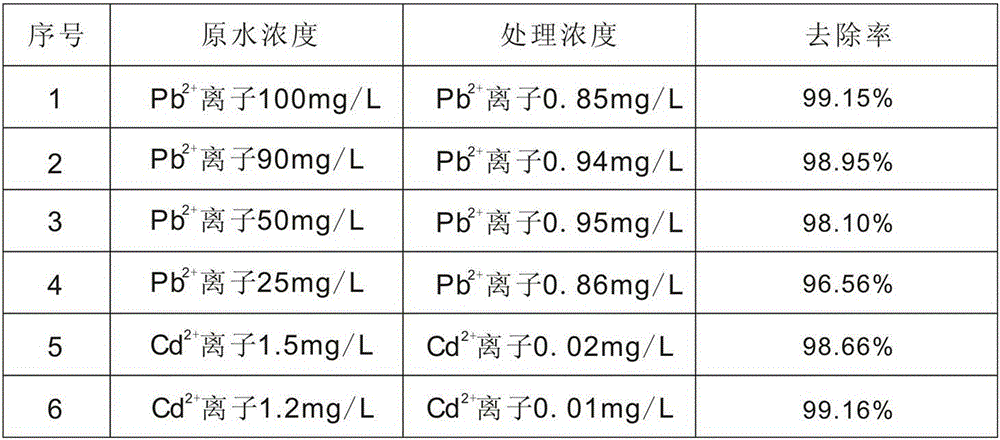

Examples

specific Embodiment 1

[0020] The configuration of sodium carboxymethyl cellulose solution has the following steps: use neutral water without salts and inclusions, control the water temperature at 40 degrees Celsius, slowly sprinkle sodium carboxymethyl cellulose into the water, and stir at 100~300r / min, the solubility is controlled at 0.1% on a dry basis, and then diluted to 0.05% before use. The dissolving ratio of the prepared sodium carboxymethyl cellulose solution is 1:80. The ratio of sodium carboxymethyl cellulose to sodium silicate is 1:10. The solubility of sodium silicate aqueous solution is 1:50.

[0021] After mixing, the flocculation precipitant, polyacrylamide and sodium carboxymethyl cellulose, is stirred and heated with a constant temperature water bath at a temperature of 20°C; the pH value of the mixture is adjusted with dilute hydrochloric acid or dilute sodium hydroxide solution, and the pH value for 6.

specific Embodiment 2

[0023] The configuration of sodium carboxymethyl cellulose solution has the following steps: use neutral water without salts and inclusions, control the water temperature at 45 degrees Celsius, slowly sprinkle sodium carboxymethyl cellulose into the water, and stir at 100~300r / min, the solubility is controlled at 0.3% on a dry basis, and then diluted to 0.05% before use. The dissolving ratio of the prepared sodium carboxymethyl cellulose solution is 1:100. The ratio of sodium carboxymethyl cellulose to sodium silicate is 1:20.

[0024] After mixing, the flocculation precipitant, polyacrylamide and sodium carboxymethyl cellulose, is stirred and heated with a constant temperature water bath at a temperature of 20°C; the pH value of the mixture is adjusted with dilute hydrochloric acid or dilute sodium hydroxide solution, and the pH value for 7.

[0025] The solubility of sodium silicate aqueous solution is 1:100.

[0026] The main reason for using sodium carboxymethyl cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com