A liquid discharge structure and a closed container with the liquid discharge structure

A technology of closed containers and liquid outlets, applied in the direction of unloading devices, etc., can solve the problems of narrow application range, high manufacturing cost, complex liquid discharge structure, etc., achieve low processing cost, reduce fluctuations and splashes, and increase flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

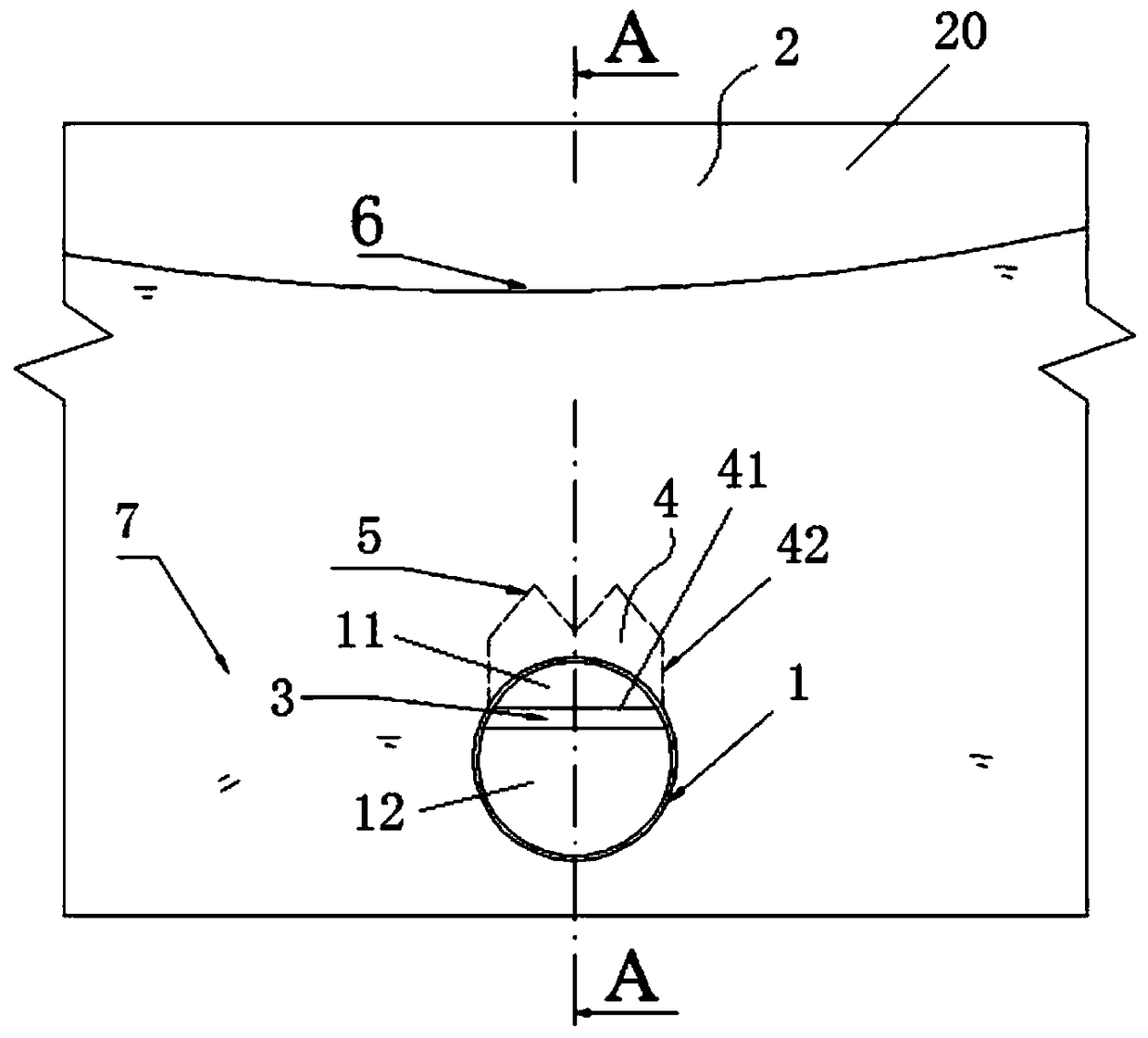

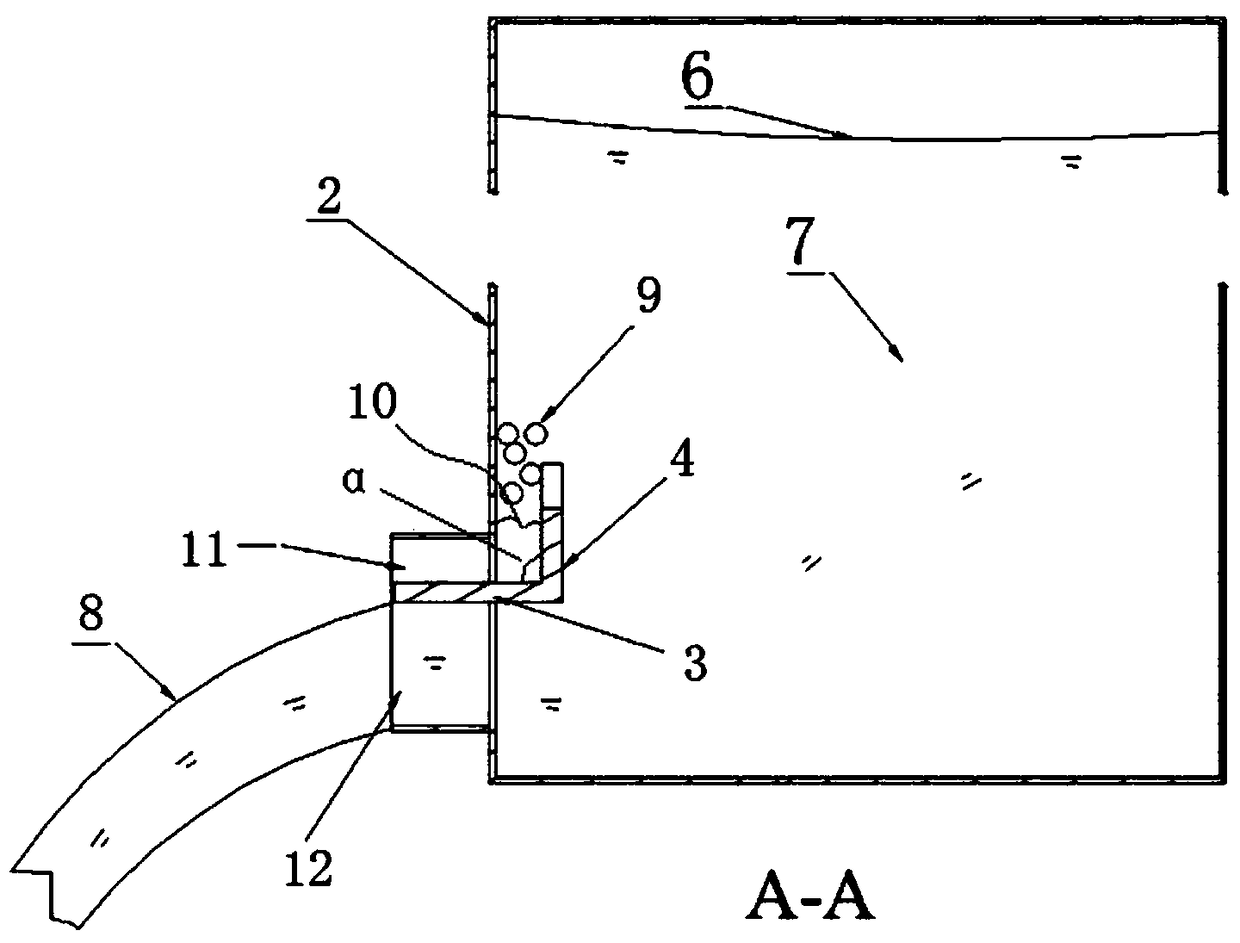

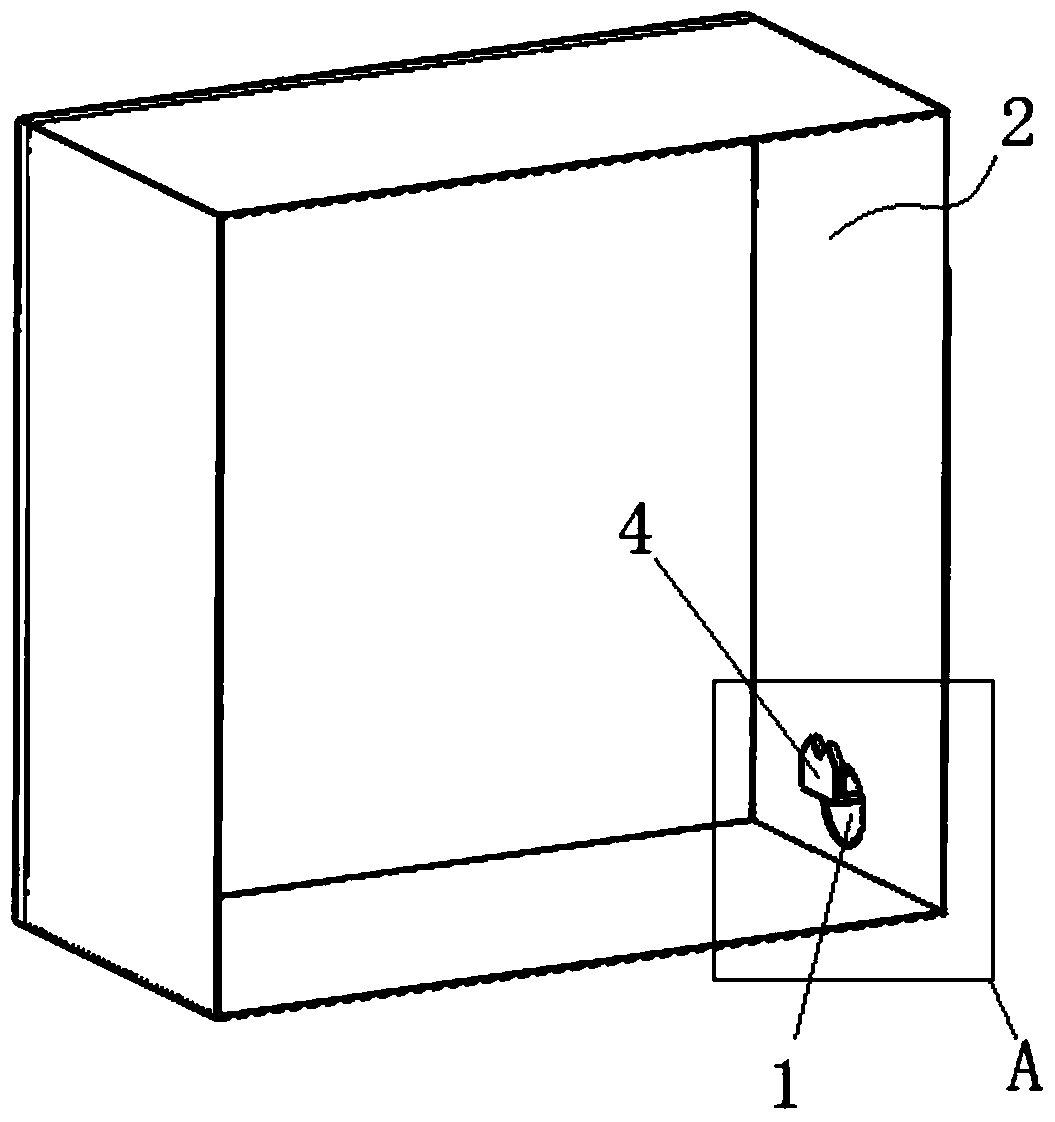

[0043] This embodiment provides a liquid drainage structure, such as Figure 1-4 As shown, it includes a liquid outlet 1, which is arranged on the airtight container 2, and is used to connect the inner cavity 20 of the airtight container 2 with the external space, and has a certain axial length; the partition plate 3 is fixedly arranged on the airtight container 2. The inside of the liquid outlet 1 is used to divide the liquid outlet 1 into an air intake channel 11 and a liquid discharge channel 12 arranged up and down; and a baffle plate 4 is fixedly installed on the The part of the partition plate 3 located inside the inner chamber 20, together with the partition plate 3 and part of the inner wall of the airtight container 2, forms a gas flow channel 10 communicating with the inlet passage 11, and the inlet The projection of the air passage 11 on the baffle 4 completely falls into the inside of the baffle 4; the longest distance between the baffle 4 and the liquid outlet 1 i...

Embodiment 2

[0055] This embodiment provides an airtight container on which the liquid drainage structure as described in Embodiment 1 is arranged.

[0056] In this embodiment, the capacity of the airtight container is 1.8 L, the diameter of the liquid outlet is 38 mm, and the cross-sectional area of the air inlet channel is 1 / 4 of the diameter of the liquid outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com