A high-efficiency storage buffer protection unloading transmission device

A transmission device and warehousing technology, which is applied in storage devices, transportation and packaging, etc., can solve the problems of difficult control and avoidance of cargo falling, high storage costs, exposure of slope transportation lines, etc., and achieve flexible control of cargo unloading speed , smooth unloading and shortened unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

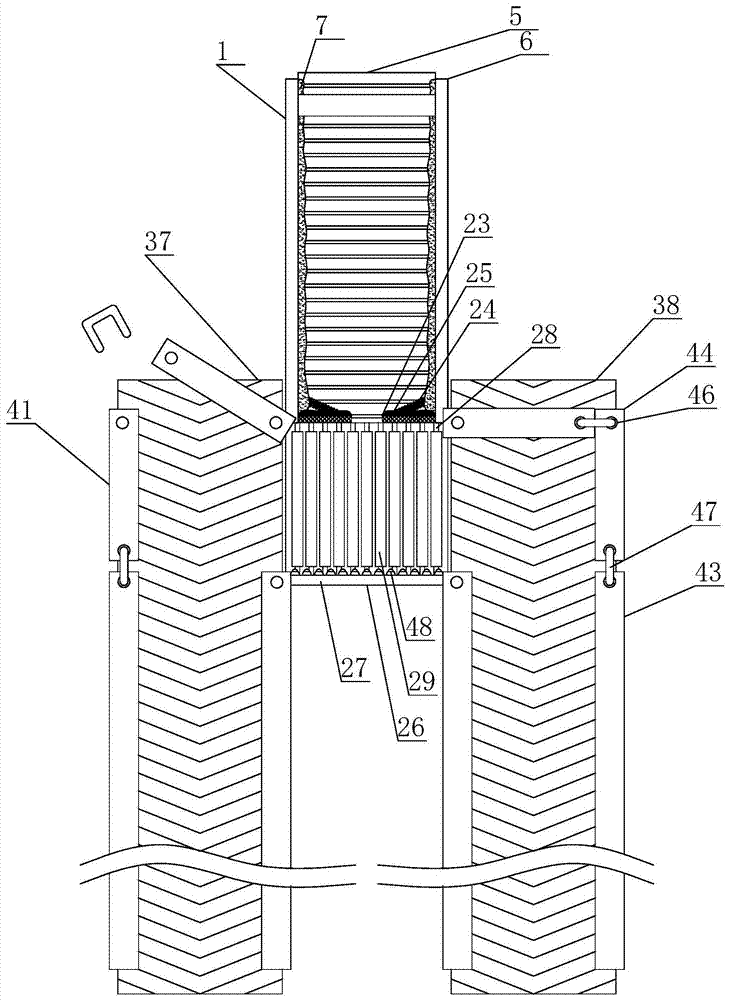

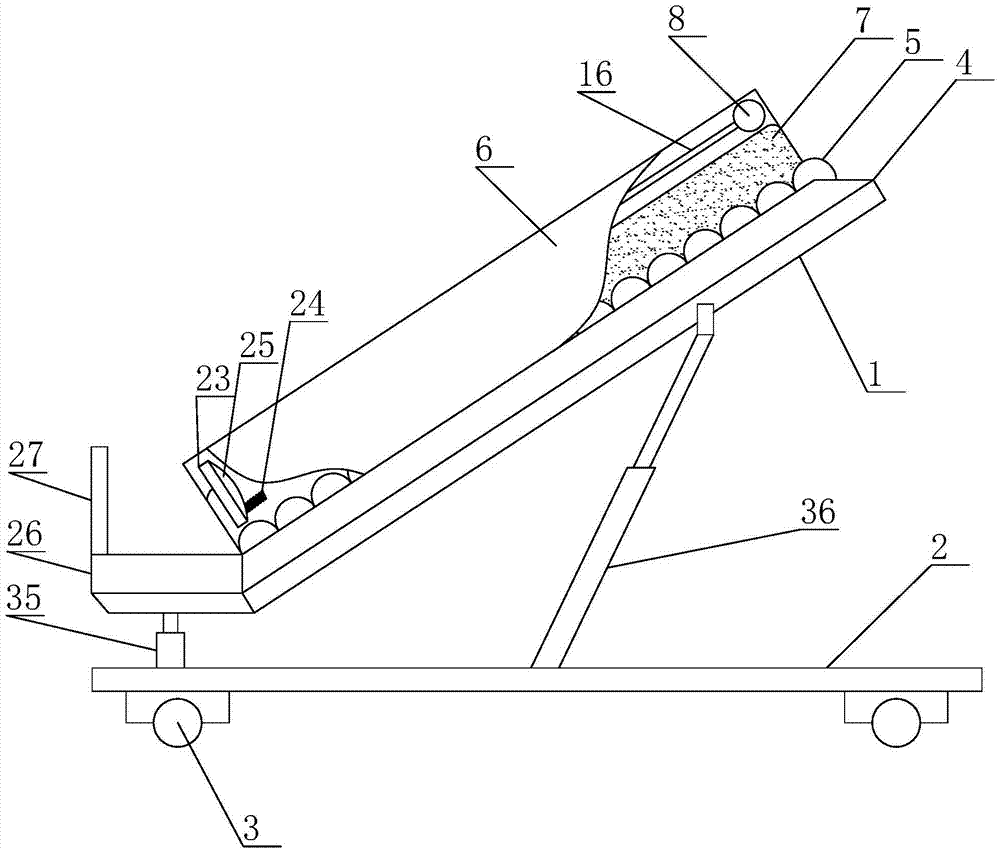

[0046] Embodiment 1: The present invention is a high-efficiency storage buffer protection unloading transmission device. The main structure includes an unloading roller line 1 and a supporting chassis 2. The unloading roller line 1 is installed on the supporting chassis 2. The supporting bottom Corner wheels 3 are symmetrically installed on the frame 2. The unloading roller line 1 includes a frame 4 and a plurality of unpowered rollers 5 installed on the frame 4. The frame 4 is a hollow rectangular frame. The unpowered roller 5 is evenly distributed on the frame 4 and its two ends are all rotatably connected with the frame 4, and both sides in the length direction of the frame 4 are provided with side baffles 6, and the inner sides of the side baffles 6 are The middle and lower part is provided with a rubber air cushion 7, and a plurality of air chambers are vertically arranged in the said rubber air cushion 7, and air holes are arranged between adjacent air chambers and are co...

Embodiment 2

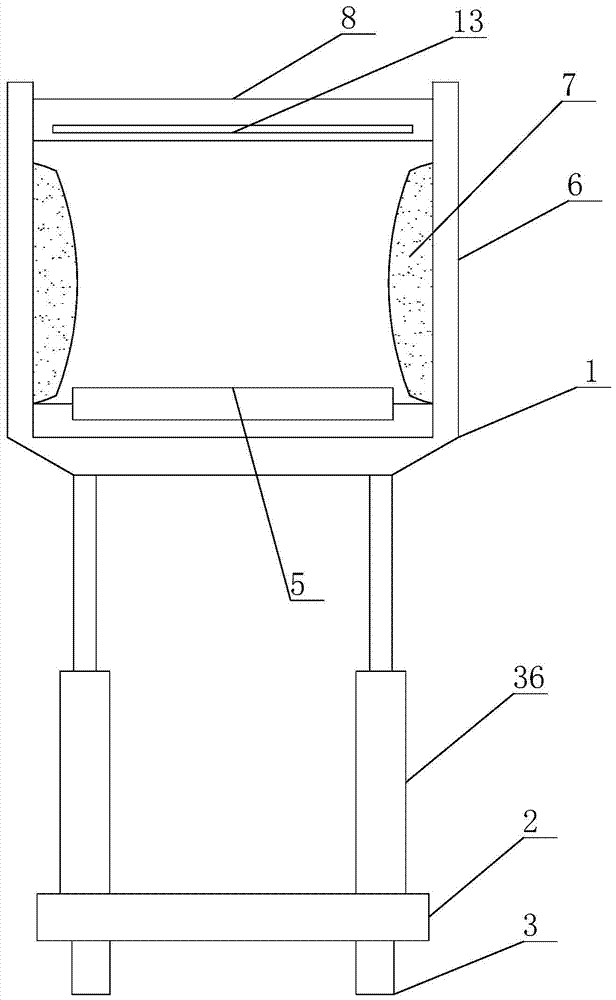

[0047] Embodiment 2: The present invention is a high-efficiency storage buffer protection unloading transmission device. The main structure includes an unloading roller line 1 and a supporting chassis 2. The unloading roller line 1 is installed on the supporting chassis 2. The supporting bottom Corner wheels 3 are symmetrically installed on the frame 2. The unloading roller line 1 includes a frame 4 and a plurality of unpowered rollers 5 installed on the frame 4. The frame 4 is a hollow rectangular frame. The unpowered roller 5 is evenly distributed on the frame 4 and its two ends are all rotatably connected with the frame 4, and both sides in the length direction of the frame 4 are provided with side baffles 6, and the inner sides of the side baffles 6 are The middle and lower part is provided with a rubber air cushion 7, and a cylindrical bobbin 8 is arranged between the two side baffles 6. The length of the bobbin 8 corresponds to the distance between the two side baffles an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com