Blocking and positioning device for buffer type conveyor

A technology of accumulative conveyors and positioning devices, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve problems such as difficult to achieve production accuracy, poor application effect, and unstable performance, so as to improve production efficiency and accuracy. Safety and security, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

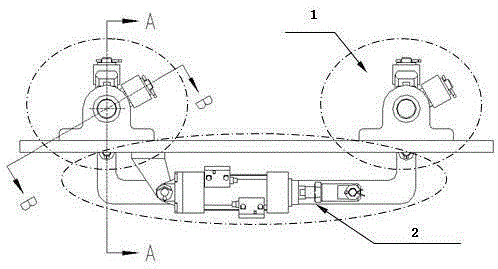

[0026] Such as Figure 1-Figure 4 As shown, a blocking and positioning device for accumulation type conveyors is composed of two sets of blocking and positioning mechanisms with identical structures and a set of synchronously rotating interlocking transmission mechanisms, which drive the blocking and positioning mechanisms to change directions.

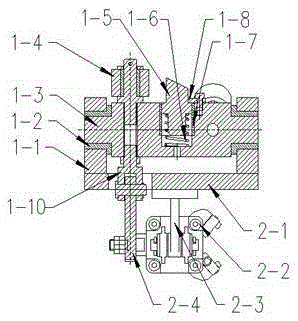

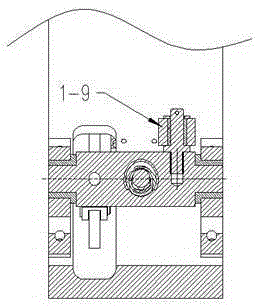

[0027] The blocking positioning mechanism 1 includes a rotating support 1-1, a rotating shaft sleeve 1-2, a rotating shaft 1-3, a blocking wheel A1-4, a positioning pin 1-5, a compression spring 1-6, and a positioning sleeve 1-7 , blocking plate 1-8, blocking wheel B1-9 and reversing drive rod 1-10.

[0028] The blocking positioning mechanism 1 is provided with two sets, which are correspondingly installed on the assembly mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com