Glass working method, glass etching liquid and glass substrate

A technology of glass substrate and processing method, which is applied in the fields of glass processing, glass etching solution, and glass substrate, can solve the problems of reduced strength, deterioration of yield, easy formation of cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

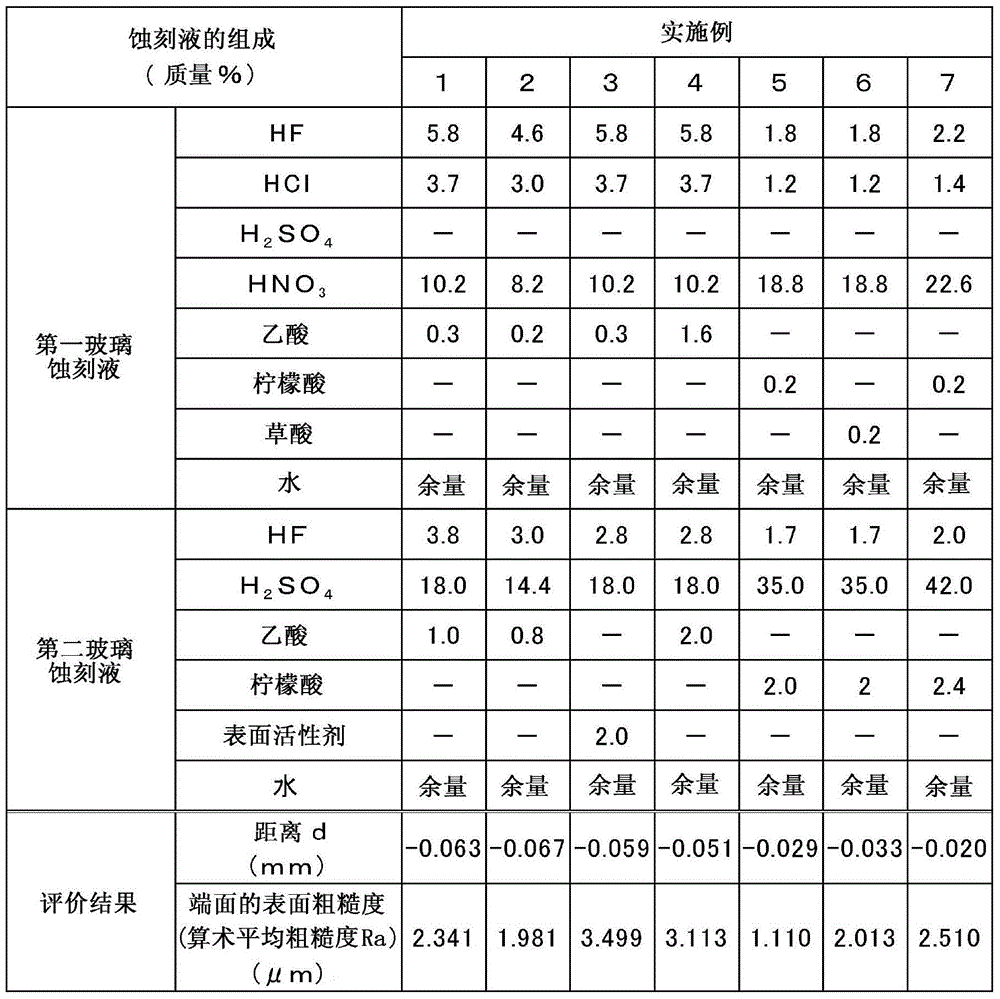

[0080] Examples of the present invention will be given below to describe the present invention in more detail, but the present invention is not limited to the following examples.

[0081] (etching of glass substrate)

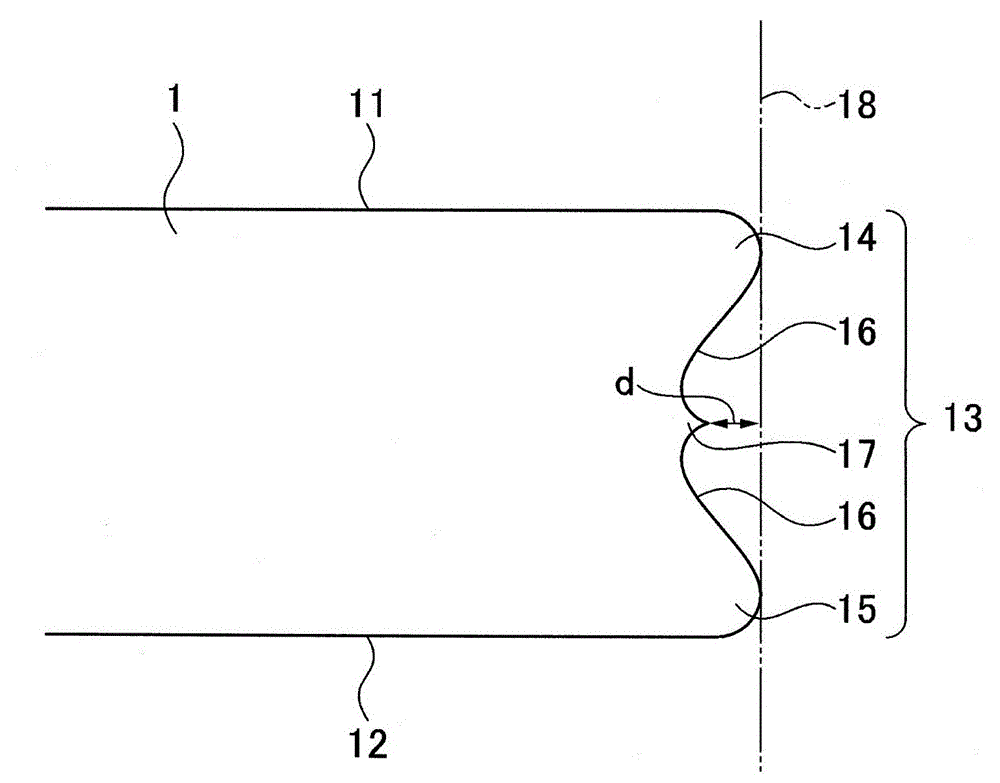

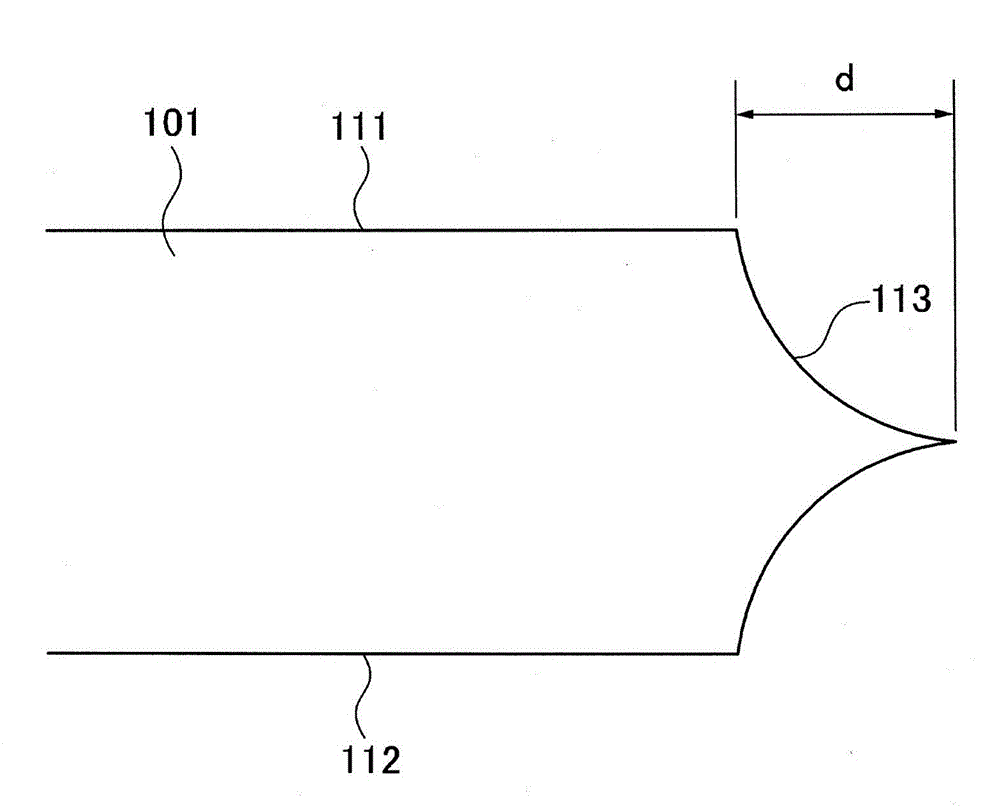

[0082] A resist composition (trade name: Glibes, manufactured by Tokyo Ohka Kogyo Co., Ltd.) was applied on both sides of a plate-shaped glass substrate (trade name: Dragontrail, manufactured by Asahi Glass Co., Ltd., thickness 0.7 mm), exposed and developed, and then An etching mask having the same pattern is formed on the pair of main planes of the glass substrate. The above-mentioned glass substrate on which the above-mentioned etching mask was formed was etched by immersing it in the first glass etchant (39° C.) having the composition shown in Table 1 or 2 for 90 minutes, and then, the above-mentioned glass substrate was taken out, and This glass substrate was etched by immersing in the 2nd glass etchant (40 degreeC) which has the composition shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com