A kind of polyethylene wax microemulsion and preparation method thereof

A technology of polyethylene wax and emulsified polyethylene wax, which is applied in the field of polyethylene wax production, can solve the problems of difficult emulsification of high melting point polyethylene wax, reduce processing costs and environmental pollution, have strong dilution stability, and reduce the types of use and the effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

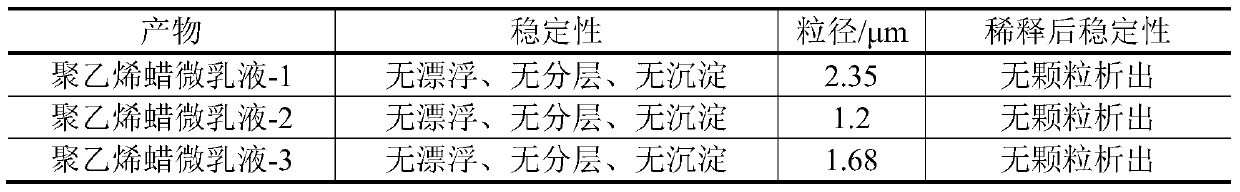

Examples

Embodiment 1

[0026] The first step, according to the mass percentage, respectively weighs 25% polyethylene wax, 20% emulsifier, 55% distilled water, the sum of the mass of the above components is 100%;

[0027] Step 2: Put the polyethylene wax in the flask and heat it to 120°C to completely melt the polyethylene wax to obtain molten polyethylene wax;

[0028] The third step: keep the temperature of the flask at 120°C, stir the molten polyethylene wax obtained in the second step at a stirring speed of 750r / min, and add HLB=10 to the molten polyethylene wax while stirring. The emulsifier (addition method is: first drip OP-6 at a speed of 10 drops / minute, and then drop Span-80 into the molten polyethylene wax at a speed of 25 drops / minute while stirring) , carry out emulsification reaction 20min, obtain emulsified polyethylene wax;

[0029] Step 4: Keep the temperature of the flask at 120°C, heat the water to 85°C, and then add the heated water to the emulsified polyethylene wax obtained in ...

Embodiment 2

[0031] The first step is to weigh 30% polyethylene wax, 25% emulsifier, and 45% distilled water according to the mass percentage, and the sum of the mass of the above components is 100%;

[0032] Step 2: Put the polyethylene wax in the flask and heat it to 130°C to completely melt the polyethylene wax to obtain molten polyethylene wax;

[0033] The third step: keep the temperature of the flask at 130°C, stir the molten polyethylene wax obtained in the second step at a stirring speed of 1000r / min, and add HLB=10.5 to the molten polyethylene wax while stirring The emulsifier (adding method is: first drip OP-6 at a speed of 15 drops / minute, and then drop Span-80 into the molten polyethylene wax at a speed of 30 drops / minute while stirring) , carry out the emulsification reaction for 30 minutes to obtain emulsified polyethylene wax-2;

[0034] Step 4: Keep the temperature of the flask at 130°C, heat the water to 90°C, and then add the heated water to the emulsified polyethylene w...

Embodiment 3

[0036] The first step, according to the mass percentage, respectively weighs 20% polyethylene wax, 25% emulsifier, 55% distilled water, the sum of the mass of the above components is 100%;

[0037] The second step: first put the polyethylene wax in the flask and heat it to 140°C to completely melt the polyethylene wax to obtain molten polyethylene wax;

[0038] The third step: keep the temperature of the flask at 140°C, stir the molten polyethylene wax obtained in the second step at a stirring speed of 1250r / min, and add HLB=11 to the molten polyethylene wax while stirring The emulsifier (addition method is: first drip OP-6 at a speed of 20 drops / minute, and then drop Span-80 into the molten polyethylene wax at a speed of 35 drops / minute while stirring) , carry out emulsification reaction 40min, obtain emulsified polyethylene wax;

[0039] Step 4: Keep the temperature of the flask at 140°C, heat the water to 95°C, and then add the heated water to the emulsified polyethylene w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com