Heat treatment mesh belt furnace

A mesh belt furnace and heating section technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of poor product performance and low yield, and achieve the effects of improving yield, simple structure, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

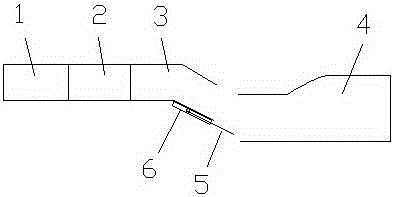

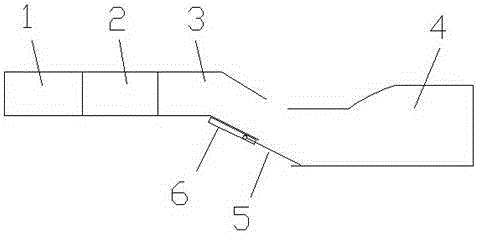

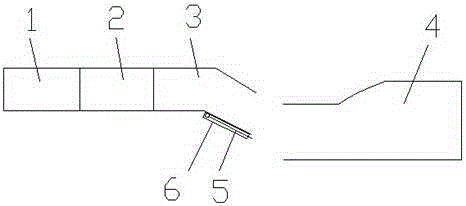

[0017] Embodiment, a kind of mesh belt furnace for heat treatment, see figure 1 , figure 2 and image 3 , including a heating section 1, a quenching section 2, a cleaning section 3 and a tempering section 4 arranged in sequence, the cleaning section 3 and the tempering section 4 are disconnected, and the bottom wall of the cleaning section 3 is provided with a push-pull connecting plate 5 and can be Connect the cleaning section 3 and the tempering section 4 or disconnect the cleaning section 3 and the tempering section 4.

[0018] Further, see Figure 4 , the bottom wall of the cleaning section 3 is provided with slots 6 on both sides along the length direction of the mesh belt furnace, and the connecting plate 5 is snapped into the slots 6 .

[0019] Further, the connecting plate 5 is provided with rollers, and the connecting plate 5 slides along the slot 6 through the rollers.

[0020] Further, the card slot 6 is arranged outside the bottom wall of the cleaning section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com