Sequential deepening grouting construction technology and device for soil covering layer on karst cave in karst area

A technology of construction technology and construction equipment, which is applied to the field of grouting construction technology and equipment to gradually deepen the overlying soil layer of karst caves in karst areas, can solve problems such as consumption of large pipes, waste of cement slurry, multiple hole formation, etc., and reduce workload. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention is described in further detail below in conjunction with accompanying drawing:

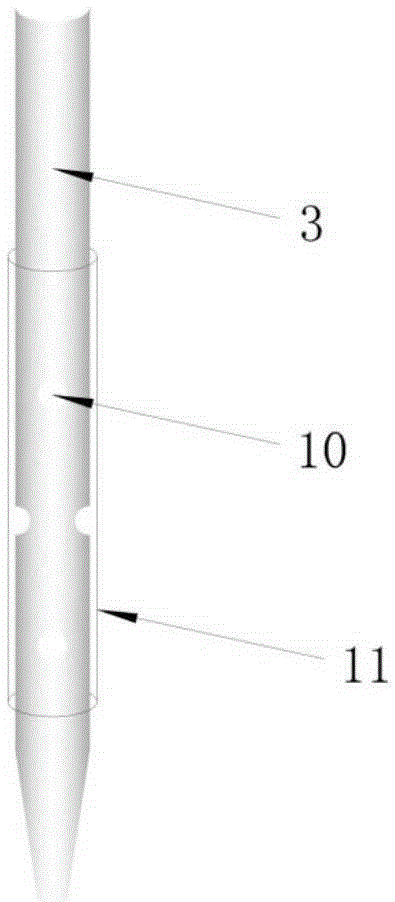

[0068] see image 3 and Figure 4 As shown, the present invention is a grouting construction equipment for sequentially deepening the overlying soil layer of a karst cave in a karst area, including a grout inlet pipe 1, a grout return pipe 2, a flower pipe 3, a pressure gauge 4 and a hole sealing device. The pulp inlet pipe 1, the pulp return pipe 2 and the flower pipe 3 are respectively equipped with a pulp inlet valve 5, a pulp return valve 6 and a flower pipe valve 7. The minimum precision of the pressure gauge 4 can reach 0.01MPa, and the maximum range can reach 2MPa. The top of the floral tube 3 is connected to the pulp inlet tube 1 and the pulp return tube 2; the bottom of the floral tube 3 has a flower hole 10, and the outside of the flower hole 10 should be wrapped with an adhesive tape 11 in advance. The adhesive tape 11 can remain intact during the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com