Light anti-seismic partition plate with integrated architectural surface and wall body and manufacturing method thereof

A decorative surface layer and partition wall panel technology, which is applied to building components, buildings, building structures, etc., can solve the problems of plastering layers and block shells, high labor intensity, and low labor efficiency, so as to improve the construction progress , Lightweight strength, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

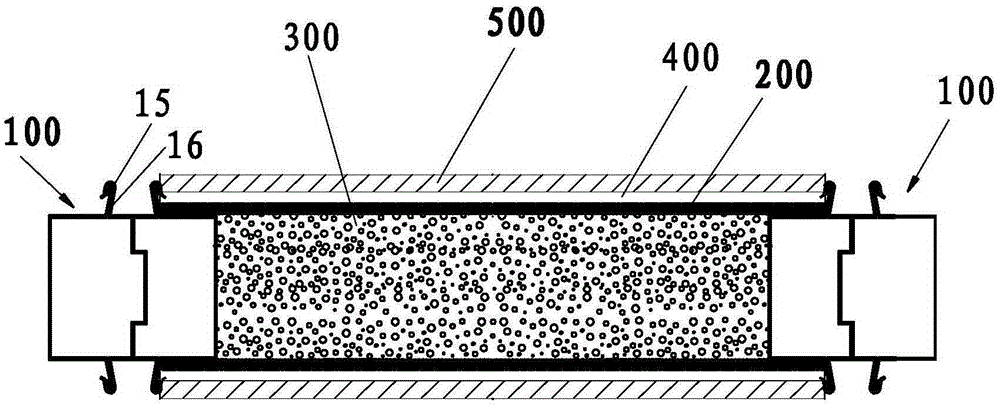

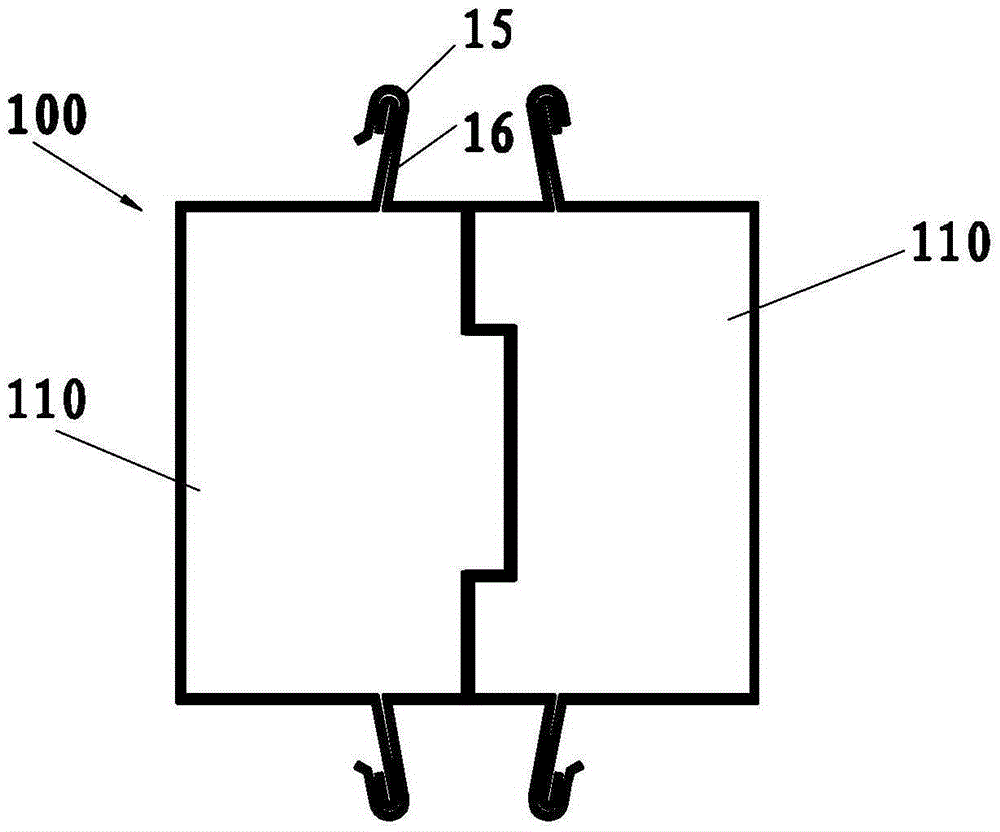

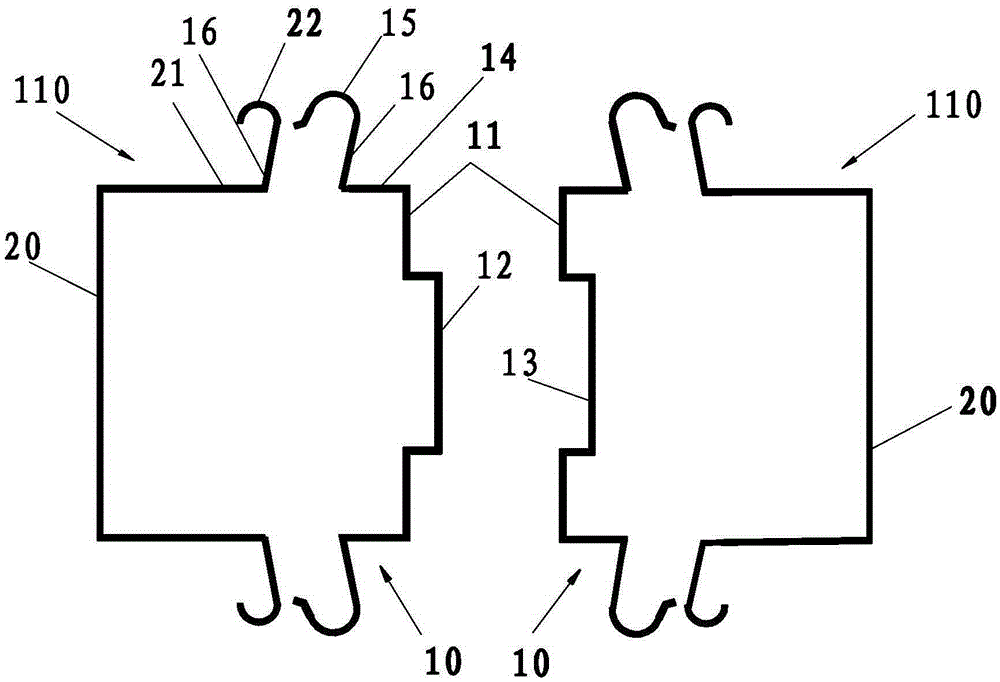

[0025] Embodiment 1: as Figure 1 to Figure 3 As shown, a light-weight anti-seismic partition wall panel in which the decorative surface layer is integrated with the wall includes a frame mold 100, an inner mold 200, a filling layer 300, a cement mortar bonding layer 400 and a decorative surface layer 500. The frame mold 100 is Back-shaped frame, the frame bar of the back-shaped frame includes two hollow half-columns 110 connected to each other. The first special-shaped profiles 10 on the column 110 are opposite to each other, and the opposing surfaces 11 of the two first special-shaped profiles 10 are respectively provided with matching connecting convex parts and connecting concave parts. In order to facilitate the connection of the two half-columns 110 and facilitate the production, the preferred connecting convex part in this embodiment is a protruding strip 12 formed by connecting three planes, and the connecting concave part is a groove 13 formed by connecting three plan...

Embodiment 2

[0031] Embodiment 2: The structure of each component included in this embodiment and the mutual positional relationship between each component are basically the same as Embodiment 1, the difference is that the cavity of the inner mold 200 is not filled with the filling layer 300, and the inner mold 200 The cavity can form a heat insulation and thermal insulation layer, which is lighter in weight. The two stressed mesh panels are covered and connected with dense mesh panels. The outer surfaces of the two stressed mesh panels are connected to the decorative surface layer 500 through the cement mortar bonding layer 400. The decorative surface layer 500 is covered on the frame mold 100, and the decorative surface layer 500, the cement mortar bonding layer 400, the inner mold 200 and the frame mold 100 are connected into one body.

[0032] In addition, if Figure 4 As shown, the shapes of the two half-columns 110 as frame molds are slightly different, and the connecting convex part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com