Construction method for auxiliary air duct structure of underground excavation station

A construction method and station technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of large amount of cross-channel excavation, long construction period, and high construction cost, so as to shorten the construction period, reduce construction costs, The effect of reducing the construction scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

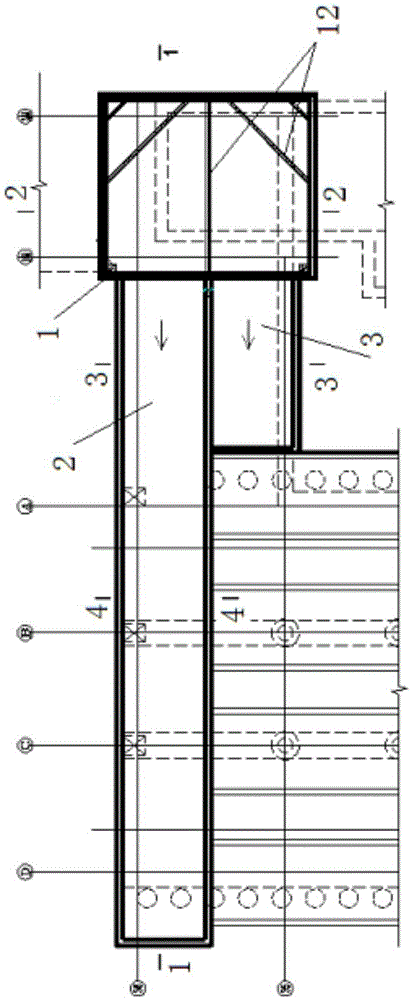

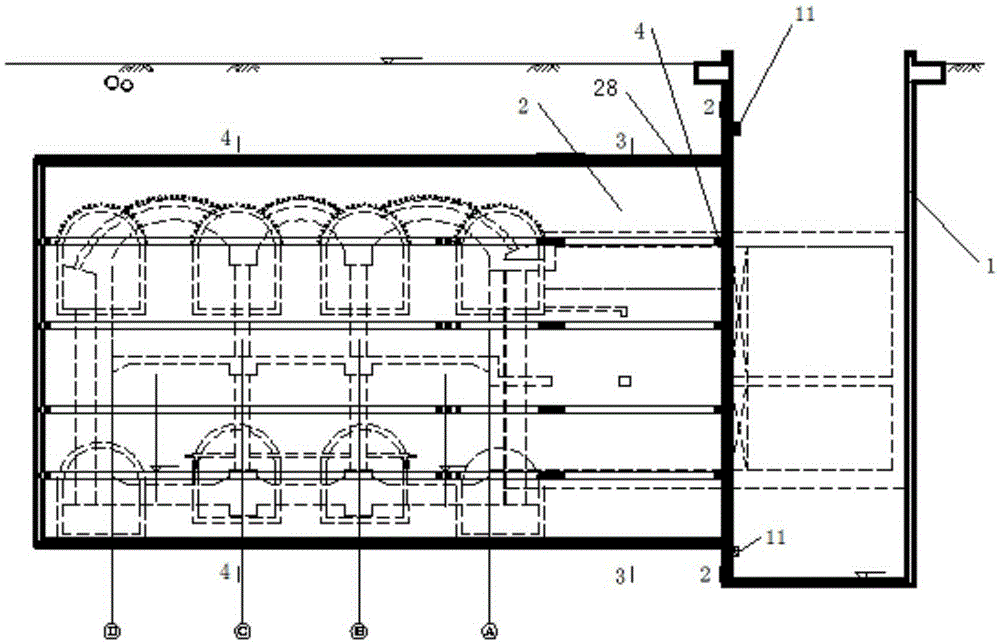

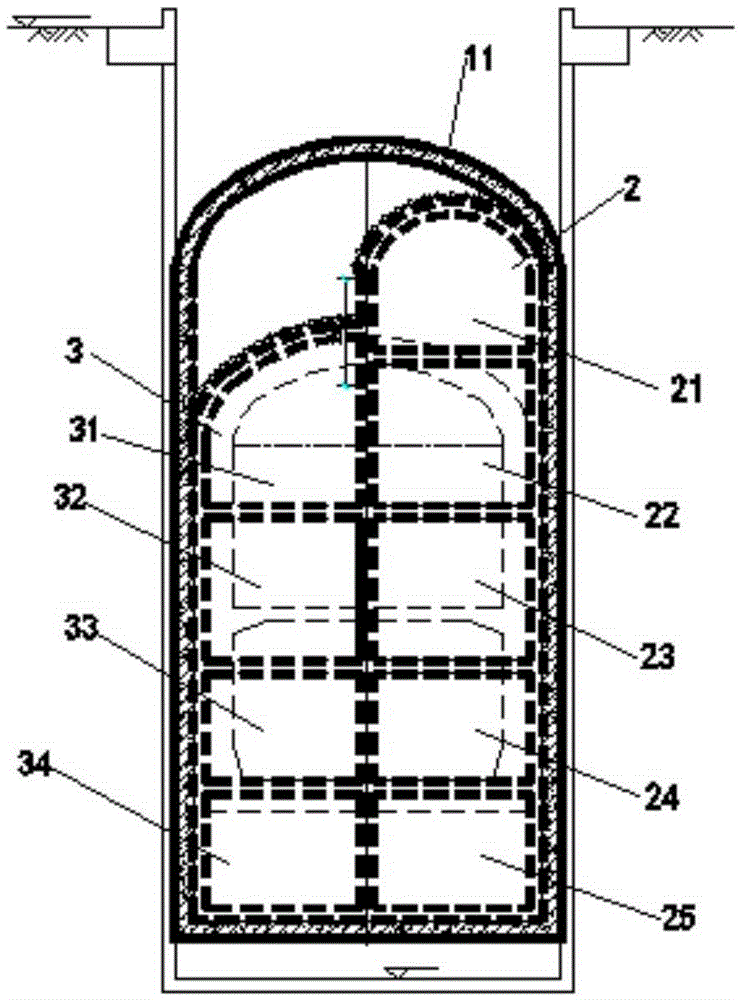

[0034] Such as Figure 1 to Figure 7 As shown, this embodiment proposes a construction method for the auxiliary air duct structure of the underground excavation station. Such as figure 1 As shown, the construction of the air duct structure includes the construction of the station cross passage and the cross passage of the air duct, and the construction methods are as follows:

[0035] Step one, such as figure 1 As shown in the figure, the vertical shaft 1 outside the ground range of the air duct is constructed by the method of hanging the shaft wall upside down, and the shaft grid steel frame (not shown in the figure) is installed in the shaft 1, and the vertical shaft grid steel frame is installed while the construction is in progress.

[0036] In order to facilitate later construction, connecting ribs are reserved on the well wall of shaft 1.

[0037] Step 2, setting temporary supports 12 in the shaft. In order to improve the support strength, the temporary support 12 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com