A cabin filter metering station

A metering station and cabin-type technology, which is applied in the direction of pipes/pipe joints/fittings, piping systems, mechanical equipment, etc., can solve the problems of increased transportation difficulty, long construction time, and leakage at joints, so as to facilitate filtering and metering work and improve Automatic processing capability, the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

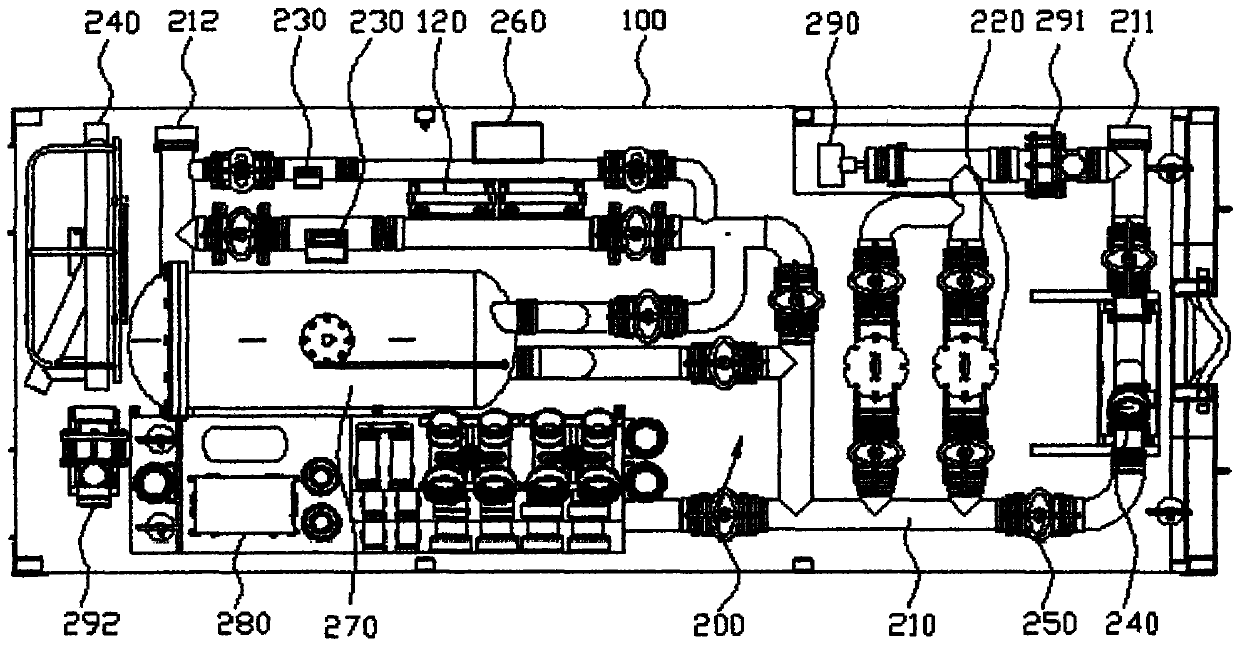

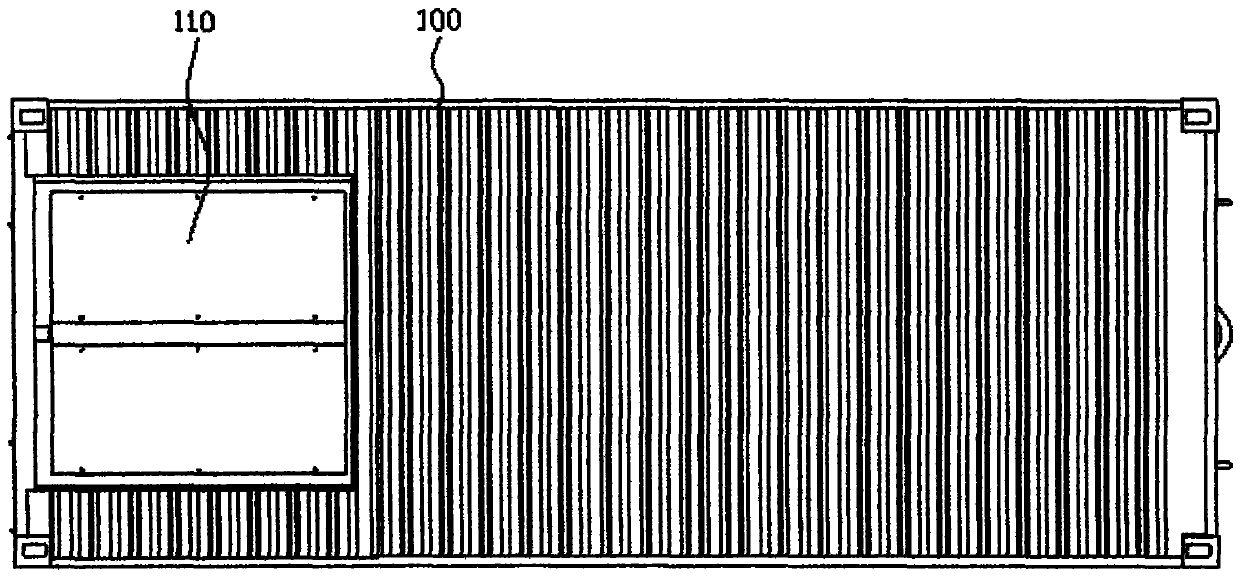

[0029] Such as figure 1 As shown, the shelter-type filter metering station of the present invention may generally include a container shelter 100 that can be transported by a person on a vehicle. The container shelter 100 is equipped with pipes with an inlet end 211 and an outlet end 212. A filter metering device for processing liquid flowing through the pipeline 210 is connected in series to the pipeline 210, and two ends of the filter metering device are respectively provided with gate valves 250 that control the filter metering device to communicate with the pipeline 210. The filter metering device may include a flow meter 230, a filter separator 270, a coarse filter 220, and a pig transceiving device 240. The flow meter 230 is used to measure the flow of liquid flowing through the coarse filter of the pipeline 210. The filter separator 270 is used to separate the mixed liquid flowing through the pipeline 210. The coarse filter 220 is used to filter fixed impurities in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com