Efficient water-cooling and air-cooling slag cooler

A technology of cooling slag machine and cold air, which is applied in lighting and heating equipment, fluidized bed combustion equipment, combustion methods, etc., and can solve the problems of low heat transfer efficiency and cooling efficiency, so as to slow down the forward speed, improve efficiency, increase The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

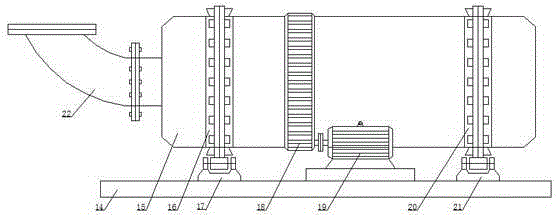

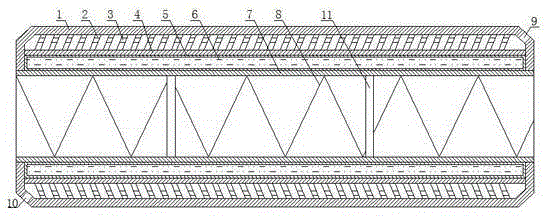

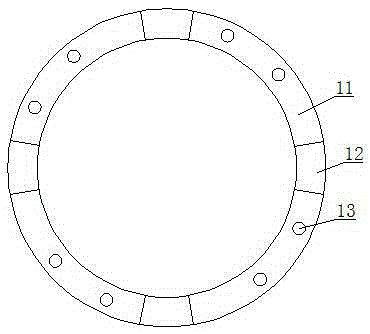

[0041] The water-cooled and air-cooled high-efficiency slag cooler in this embodiment includes a base on which a cold slag cylinder is arranged. The front support wheel and the rear support ring are respectively equipped with a front support wheel device and a rear support wheel device installed on the base. A ring gear is installed on the outer wall of the cold slag cylinder between the front support ring and the rear support ring. The device meshes; the cold slag cylinder includes an inner cylinder and an outer cylinder, the outer cylinder is sleeved on the periphery of the inner cylinder and forms a cavity, and a cooling water inlet and a cooling water outlet are opened on the outer cylinder, and the cooling water The inlet and the cooling water outlet are connected to the cavity, and the inner wall of the inner cylinder is provided with a spiral deflector, and a middle cylinder is provided between the inner cylinder and the outer cylinder, and a vacuum is formed between the...

Embodiment 2

[0043] The water-cooled and air-cooled high-efficiency slag cooler in this embodiment includes a base on which a cold slag cylinder is arranged. The front support wheel and the rear support ring are respectively equipped with a front support wheel device and a rear support wheel device installed on the base. A ring gear is installed on the outer wall of the cold slag cylinder between the front support ring and the rear support ring. The device meshes; the cold slag cylinder includes an inner cylinder and an outer cylinder, the outer cylinder is sleeved on the periphery of the inner cylinder and forms a cavity, and a cooling water inlet and a cooling water outlet are opened on the outer cylinder, and the cooling water The inlet and the cooling water outlet are connected to the cavity, and the inner wall of the inner cylinder is provided with a spiral deflector, and a middle cylinder is provided between the inner cylinder and the outer cylinder, and a vacuum is formed between the...

Embodiment 3

[0045] The water-cooled and air-cooled high-efficiency slag cooler in this embodiment includes a base on which a cold slag cylinder is arranged. The front support wheel and the rear support ring are respectively equipped with a front support wheel device and a rear support wheel device installed on the base. A ring gear is installed on the outer wall of the cold slag cylinder between the front support ring and the rear support ring. The device meshes; the cold slag cylinder includes an inner cylinder and an outer cylinder, the outer cylinder is sleeved on the periphery of the inner cylinder and forms a cavity, and a cooling water inlet and a cooling water outlet are opened on the outer cylinder, and the cooling water The inlet and the cooling water outlet are connected to the cavity, and the inner wall of the inner cylinder is provided with a spiral deflector, and a middle cylinder is provided between the inner cylinder and the outer cylinder, and a vacuum is formed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com