Spiral heat dissipation aluminum alloy profile

An aluminum alloy, snail-shaped technology, applied in the field of profiles for inductive aluminum alloy radiators, can solve the problems of low heat dissipation efficiency, inability to form large convection, and aluminum alloy billets are prone to wrinkles or cracks, etc., to improve heat dissipation efficiency. , The effect of large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

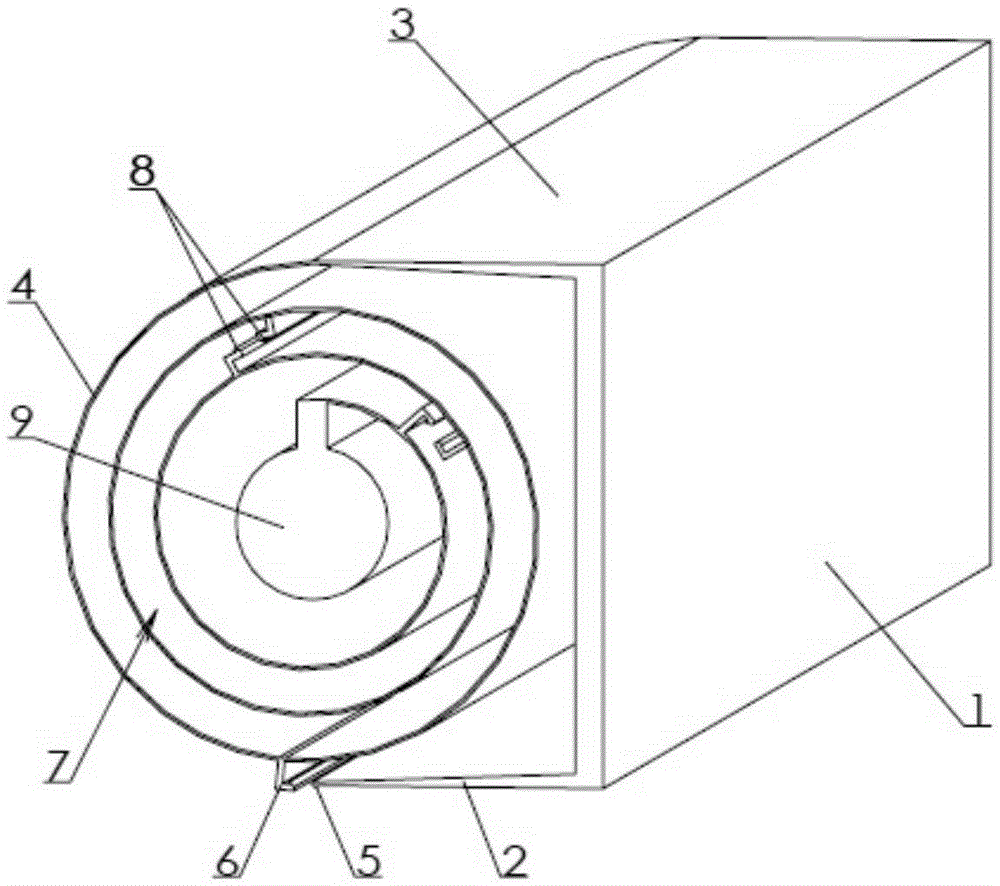

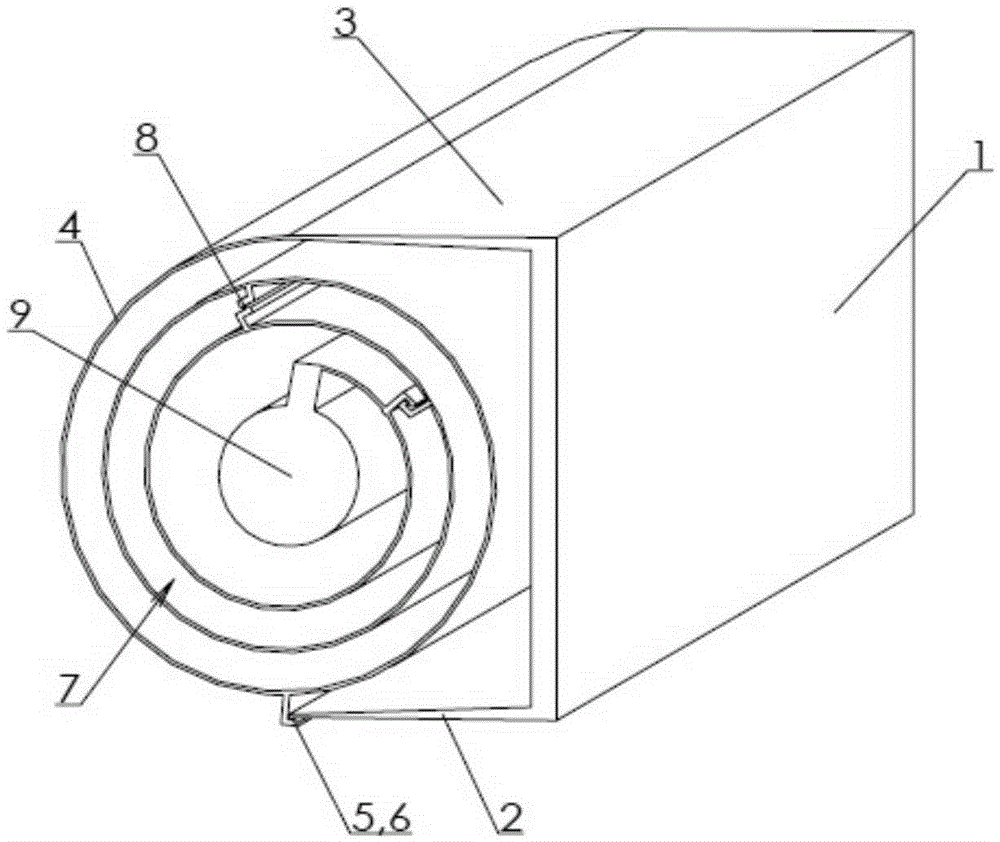

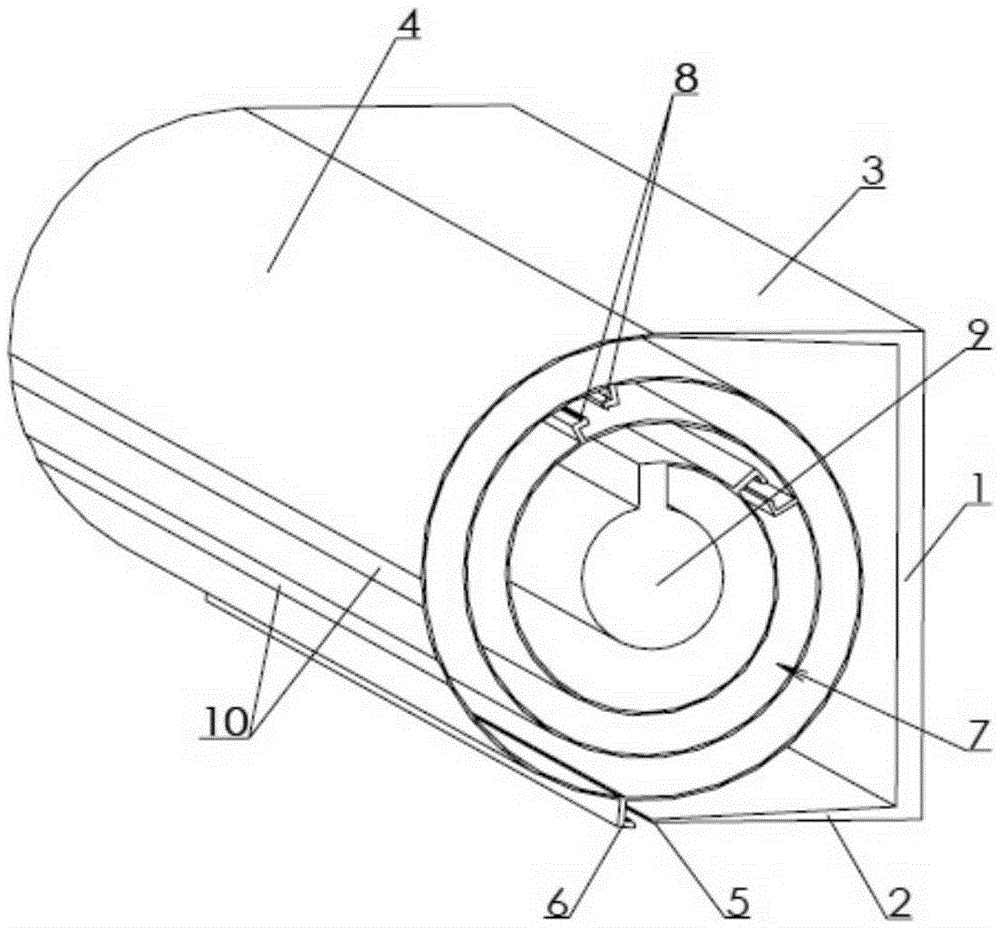

[0013] Examples of the present invention figure 1 , 2 As shown, the spiral aluminum alloy heat dissipation profile includes a main base plate 1, a left wing plate 2 and a right wing plate 3. The main base plate, the left wing plate and the right wing plate are all strip-shaped plates, and one side of the main base plate is a heat dissipation connection surface. Connect the heating components, the left wing and the right wing are respectively connected to the two sides of the other side of the main substrate opposite to the heat dissipation surface, the left wing and the right wing are respectively perpendicular to the connection surface and the longitudinal direction is consistent with the longitudinal direction of the main substrate, and the right wing is connected There is a volute wing 4, the volute wing 4 is in a curled state, the outer end of the volute wing is connected to the right wing plate, the volute wing is curled between the left wing plate and the right wing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com