Self-balancing buried pipeline and soil interaction test device

A self-balancing technology for buried pipelines, applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems of large deformation, damage, and threats to the operation of buried pipelines, and achieve the effect of saving equipment resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

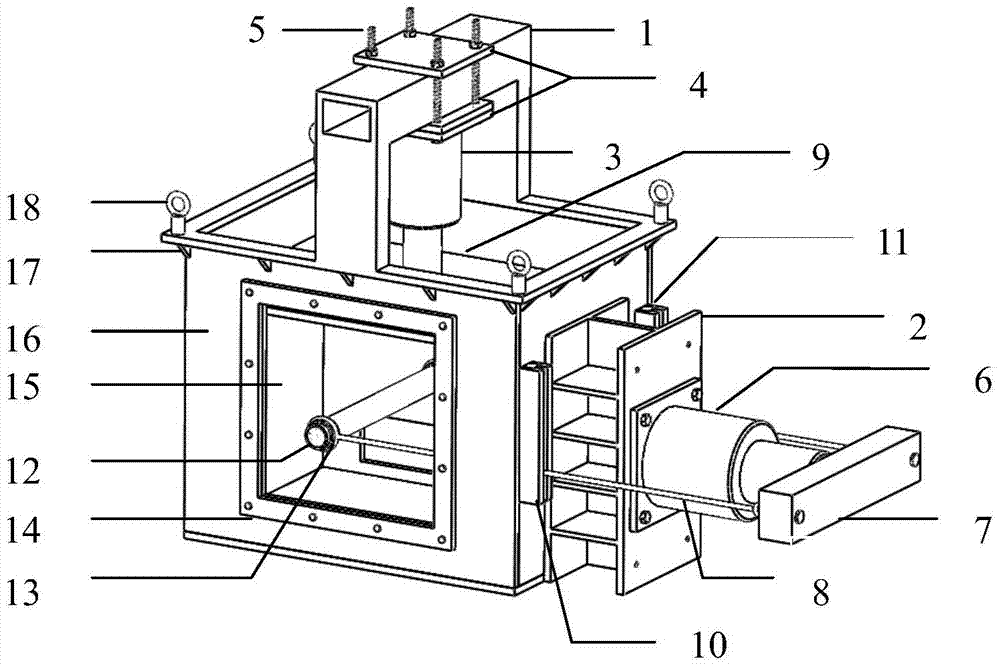

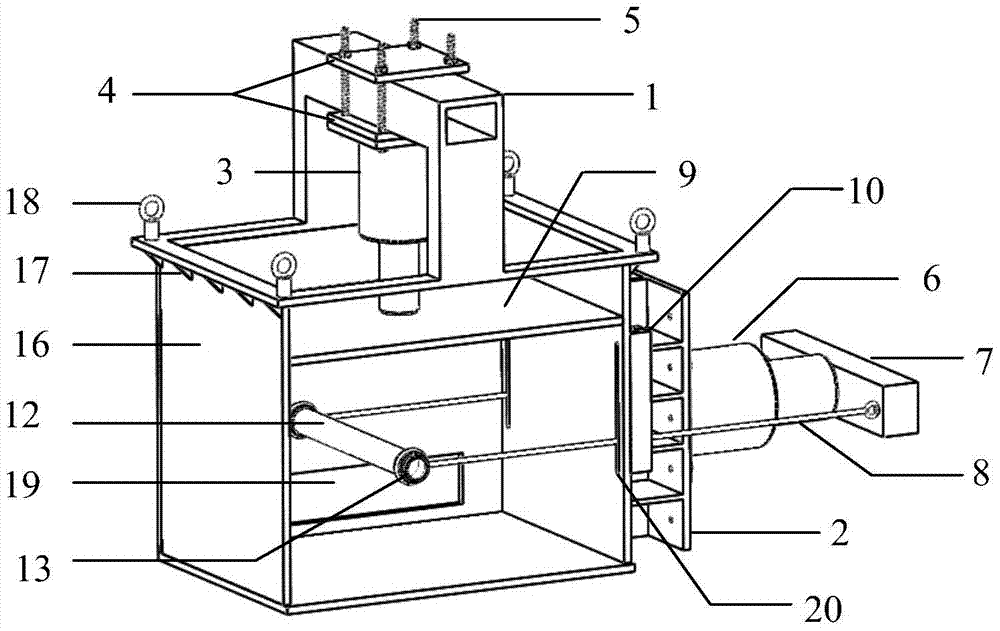

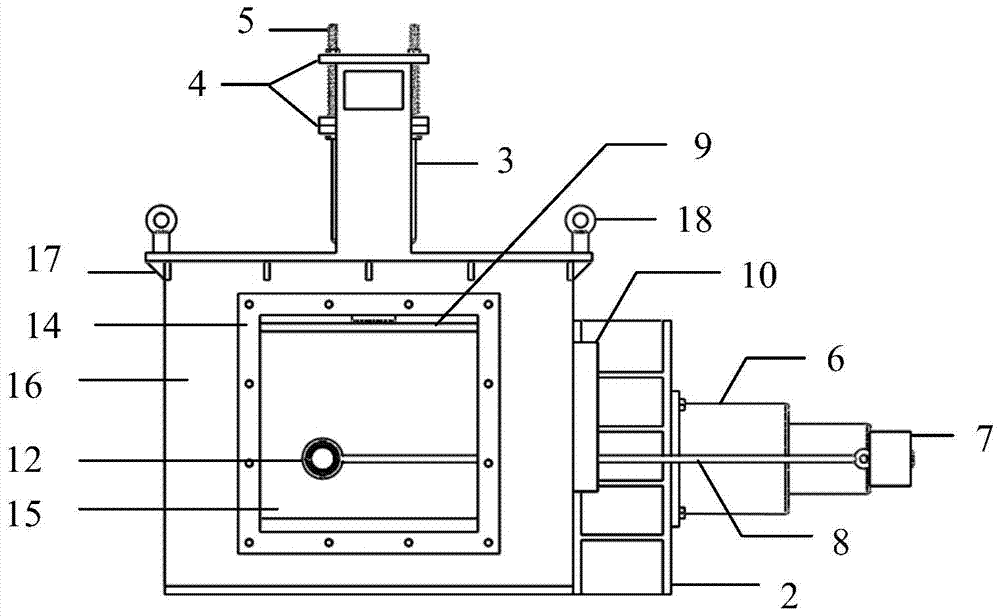

[0035] The present invention is described in detail below in conjunction with accompanying drawing: Self-balancing buried pipeline and soil interaction test device, see attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 , attached Figure 8 , including pipe (12), pipe collar (13), set screw (21), horizontal reaction force frame (2), vertical reaction force frame (1), horizontal actuator (6), vertical actuator ( 3), box body (16), plexiglass observation window (15), observation window steel frame (14), steel strand (8), stiffener (17), soil retaining slot (10), earth retaining plank ( 11), vertical loading backing plate (9), horizontal loading baffle (7), back soil retaining steel plate (19), installation backing plate (4) and bolt rod (5).

[0036] In the present invention, both the horizontal reaction force frame (2) and the vertical reaction force frame (1) are directly welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com