Brake block appearance defect multi-station online detection device and method

A technology for appearance defects and detection devices, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as high equipment cost, slow detection speed, and poor objectivity of quality standards, so as to improve work efficiency and reduce equipment. Cost, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

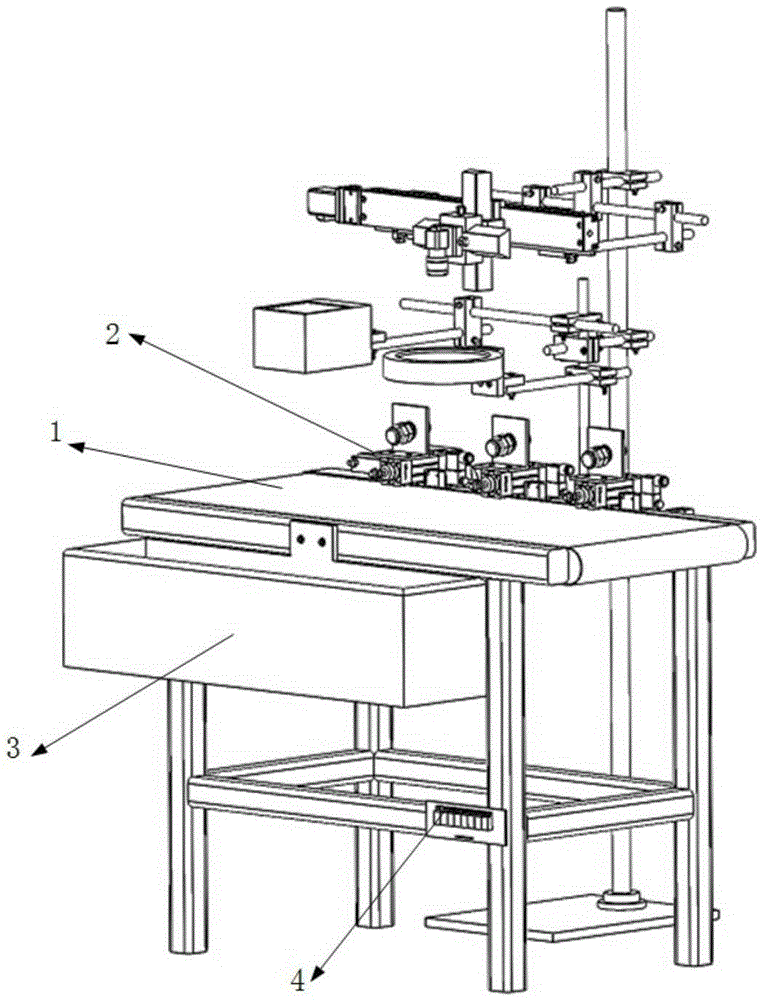

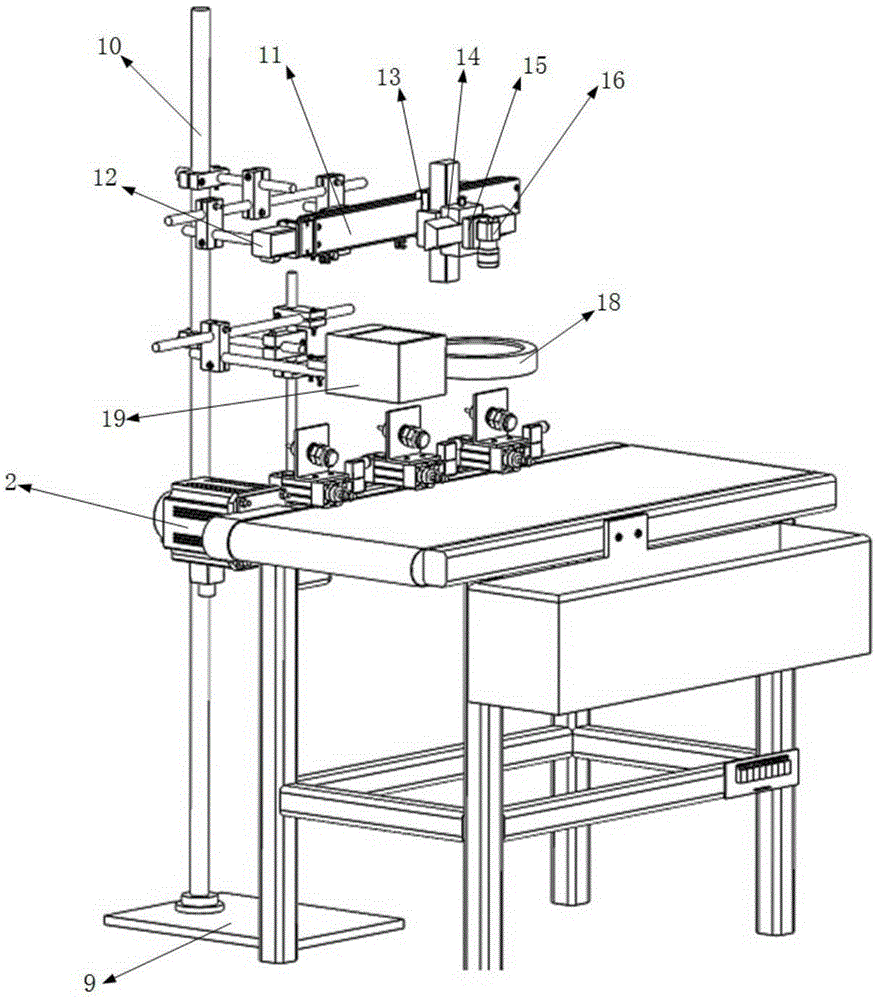

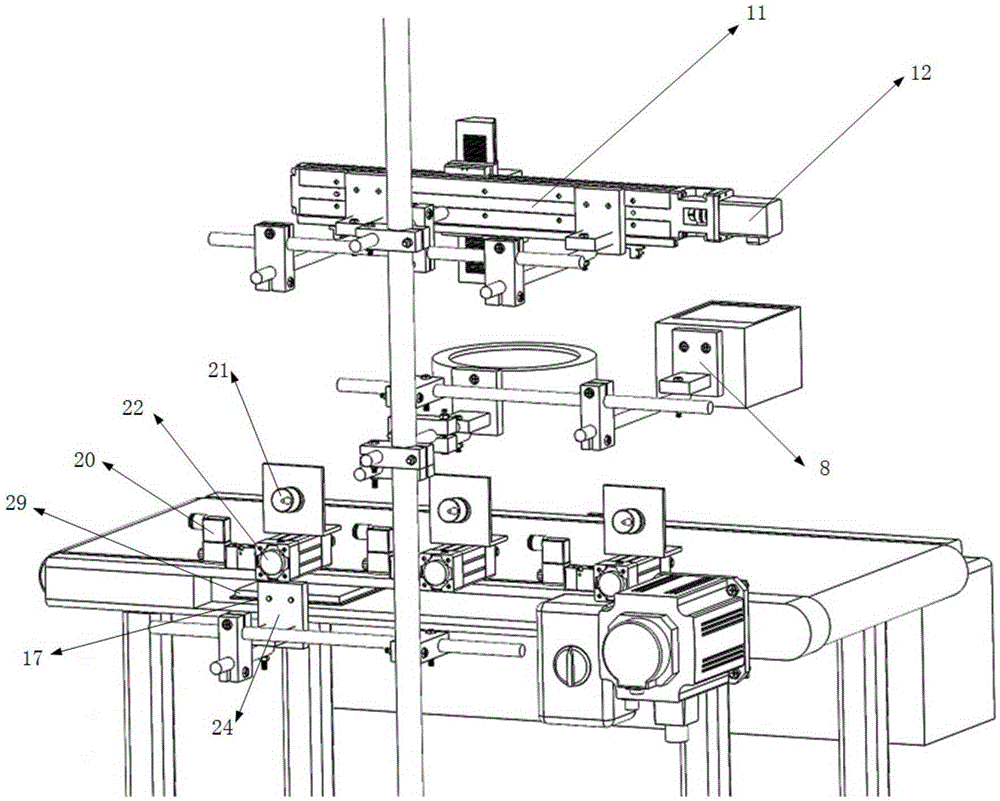

[0039] Such as figure 1 with figure 2 As shown, the present invention includes a conveyor belt 1 for transmitting brake pads, a DC motor and a governor 2, and a defective product receiving box 3; The conveyor belt 1 is running, and the bracket 10 is vertically and fixedly installed on the base 9 placed on the ground. The bracket 10 is located on the side of the conveyor belt 1; the conveyor belt 1 is provided with a first station, a second station and a third station in sequence along the conveying direction. A backlight light source module 17 is installed between the upper and lower belt surfaces of the conveyor belt 1 at the first station, a ring light source module 18 is installed above the conveyor belt 1 at the second station, and the same The axial light source module 19 is equipped with an industrial camera module for collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com