Fault diagnosis method of cable joint and fault diagnosis device of cable joint

A technology for cable joints and fault diagnosis, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of accelerated insulation aging at joints, cable fires, and increased probability of partial discharge, avoiding potential safety hazards and low accuracy requirements. , the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

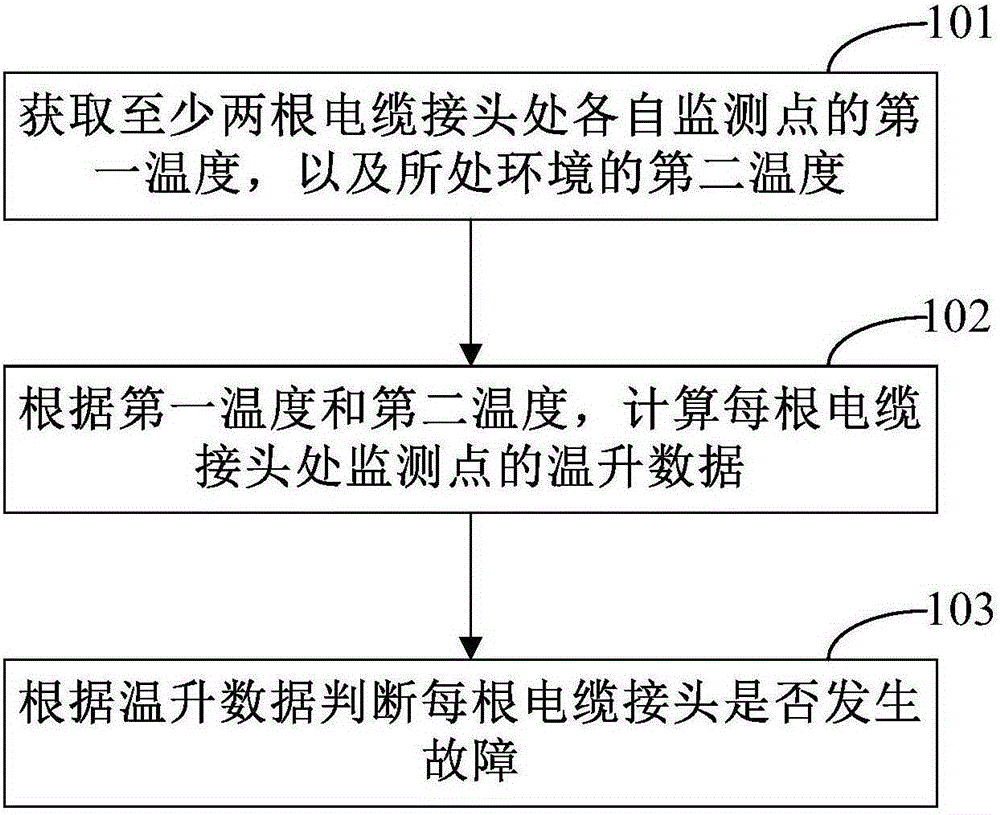

[0021] figure 1 It is a schematic flow chart of a fault diagnosis method for a cable joint according to Embodiment 1 of the present invention, as figure 1 As shown, the fault diagnosis methods for cable joints include:

[0022] Step 101: Obtain first temperatures of respective monitoring points at at least two cable joints, and second temperatures of environments where at least two cable joints are located.

[0023] In practical applications, the location of the monitoring point can be determined according to the actual conditions on site and the reliability of the equipment. Generally, the insulation sheath at the cable joint is selected as the location of the monitoring point. Correspondingly, the first temperature may be the temperature of a certain monitoring point on the insulation sheath of each cable joint, which may be collected by a temperature measuring sensor and / or an infrared temperature measuring device to obtain the first temperature of each monitoring point at...

Embodiment 2

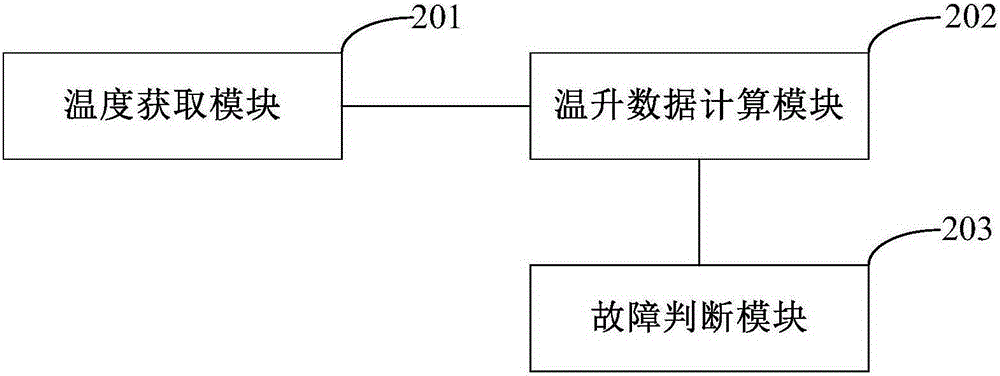

[0045] figure 2 It is a schematic structural diagram of a fault diagnosis device for a cable joint according to Embodiment 2 of the present invention. It can be used to execute the steps of the fault diagnosis method for the cable joint in Embodiment 1 of the present invention.

[0046] refer to figure 2 , the cable joint fault diagnosis device includes a temperature acquisition module 201 , a temperature rise data calculation module 202 and a fault judgment module 203 .

[0047] The temperature obtaining module 201 is used to obtain the first temperature of each monitoring point at the at least two cable joints, and the second temperature of the environment where the at least two cable joints are located.

[0048] Preferably, the temperature acquisition module 201 includes a temperature measurement sensor and / or an infrared temperature measurement device.

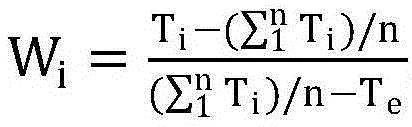

[0049] The temperature rise data calculation module 202 is used to calculate the temperature rise data of the monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com