A high-precision clamping and positioning device for optical fiber

A clamping positioning and high-precision technology, which is applied in the field of clamping and positioning devices and optical fiber high-precision clamping and positioning devices, can solve the problems of low processing and clamping positioning efficiency and precision, complex connecting components, and easy bending of optical fibers. To achieve the effect of easy and convenient clamping, lower production cost, convenient installation and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

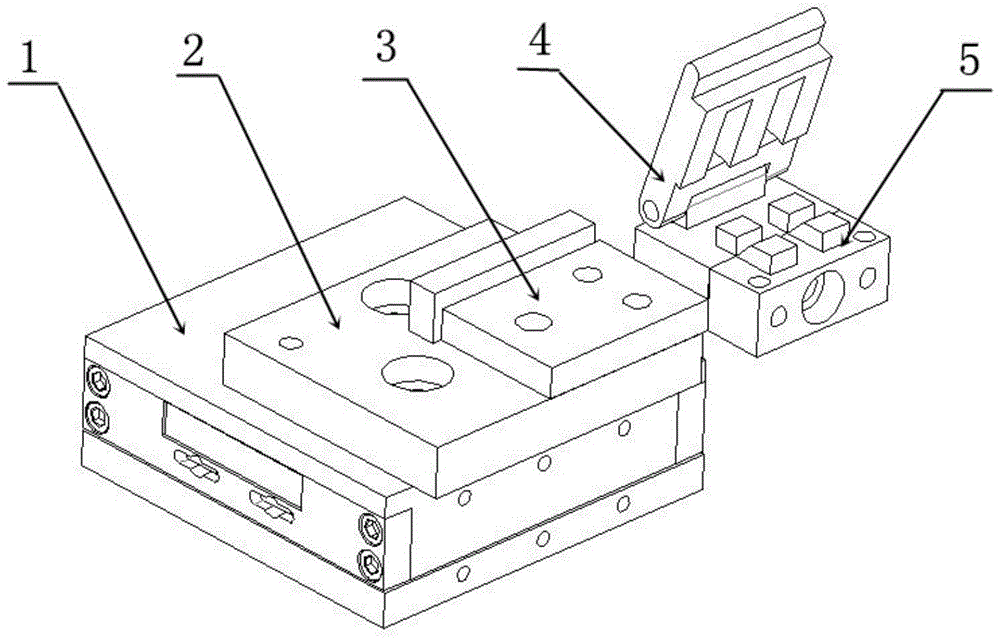

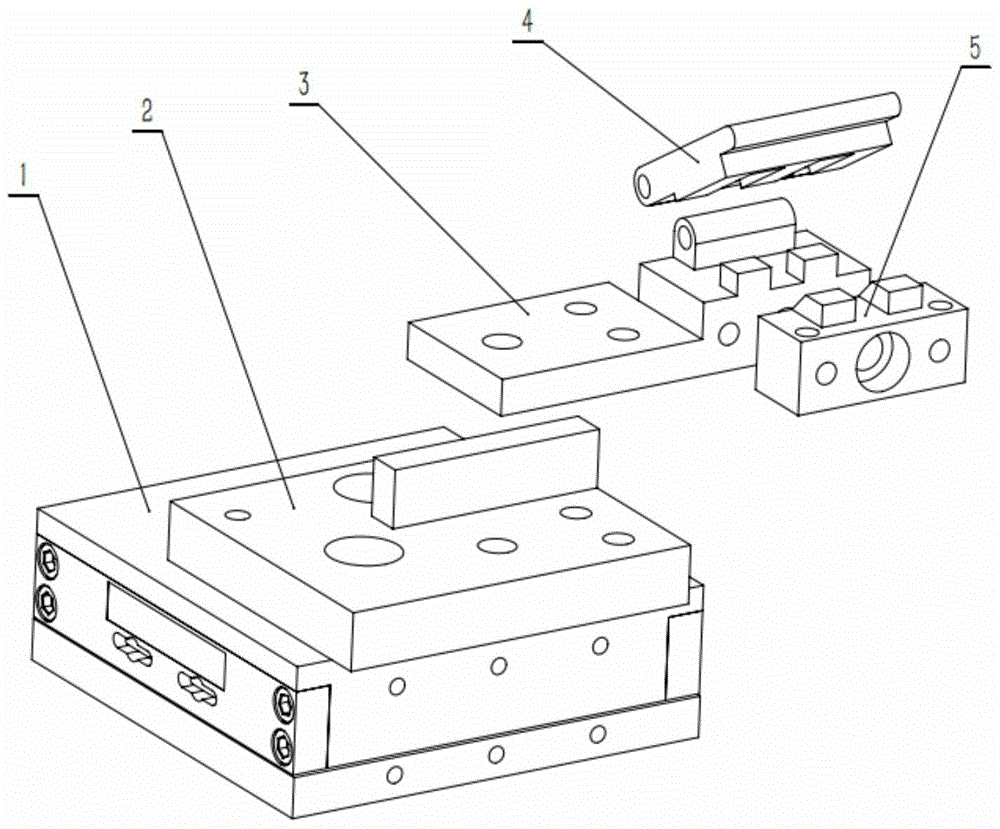

[0022] This embodiment is a high-precision optical fiber clamping and positioning device.

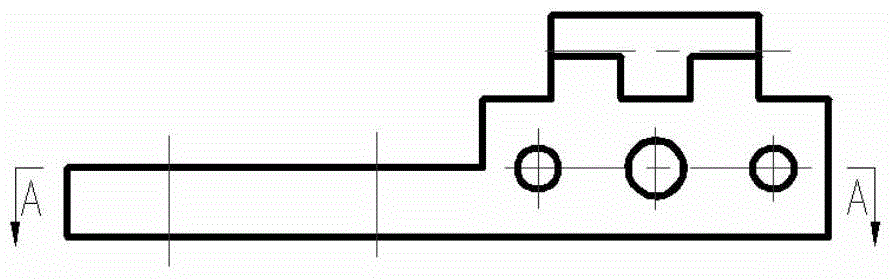

[0023] refer to figure 1 ~ Fig. 6, the optical fiber high-precision clamping and positioning device of this embodiment is composed of a mobile platform 1, a connecting plate 2, a clamping block 5, a positioning base 3, and a clamping block pressing plate 4; the mobile platform 1 is a connecting plate 2, a positioning base The parts of seat 3, clamping block pressing plate 4 and clamping block 5 are connected to provide support.

[0024] The clamping block 5 has a rectangular parallelepiped structure. There is a screw hole in the center of the front surface of the clamping block 5. Two positioning pin holes are located on both sides of the central screw hole. The positioning pin holes are conical with a taper of 1:50; the two tapers are Put the 1:50 tapered pin into the positioning pin hole and apply force to fix the position of the clamping block 5 and the positioning base 3, and put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com