Water supply system control device used for chemical fiber production

A water supply system and control equipment technology, applied in the field of chemical fiber production, can solve the problems of complex debugging, high cost, large volume, etc., and achieve the effect of simplified system circuit, low price, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

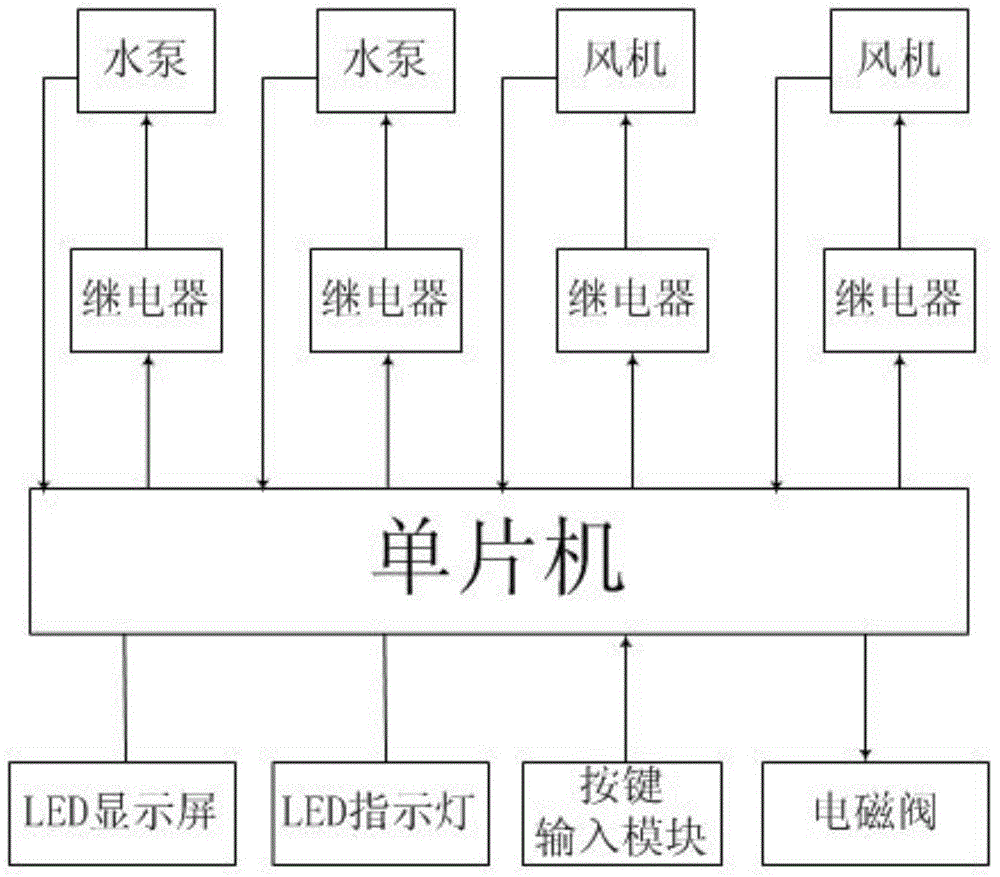

[0017] Such as figure 1 As shown, a water supply system control device for chemical fiber production, including a solenoid valve (Huatong K22JD), a water pump and a fan, is characterized in that it uses a single-chip microcomputer (MOTOROLA-M68HC12) as a controller; the signal output terminal of the single-chip microcomputer is connected to the electromagnetic The signal input end of the valve is connected, and the signal output end of the single-chip microcomputer is connected with the signal input end of the water pump by a relay (Schneider SSR), and the signal output end of the single-chip microcomputer is connected with the signal input end of the fan by a relay; The signal output end of the single chip microcomputer is connected with the signal input end.

[0018] The quantity of the water pump and the blower fan of the present invention are both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com