Steel ball counter based on single-chip microcomputer

A technology of single-chip microcomputer and counter, which is applied in the field of mechanical and electrical integration machinery and equipment, can solve the problems of tediousness, forgetting the number of counts, troubles, etc., and achieve the effect of high counting accuracy, good economy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

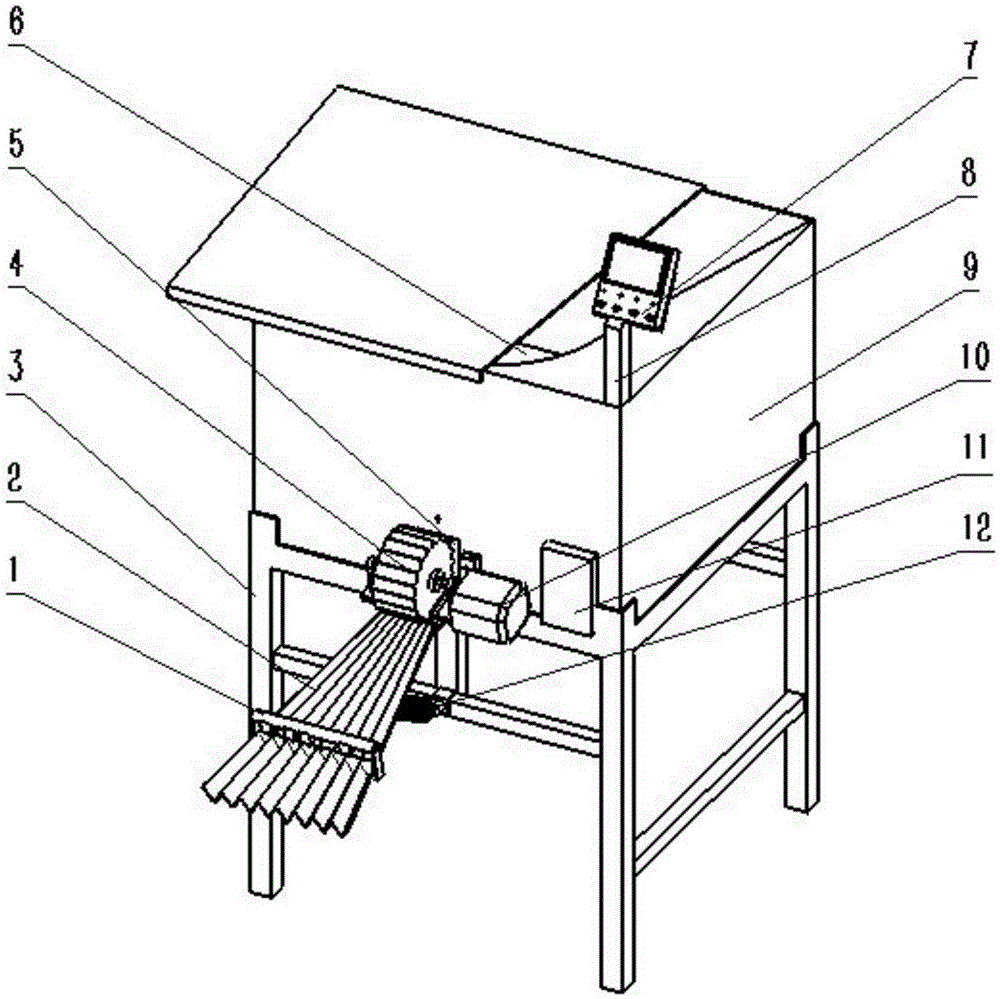

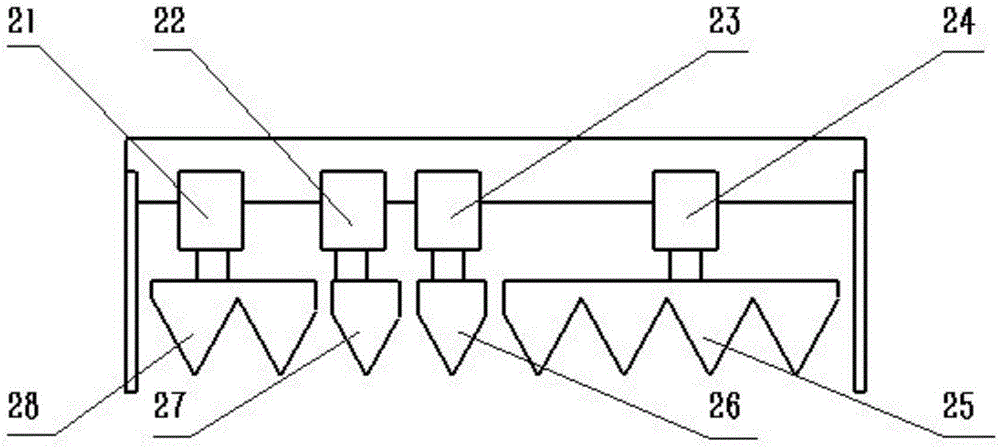

[0032] Attached below Figure 1 to Figure 8 The specific embodiment of the present invention is described further:

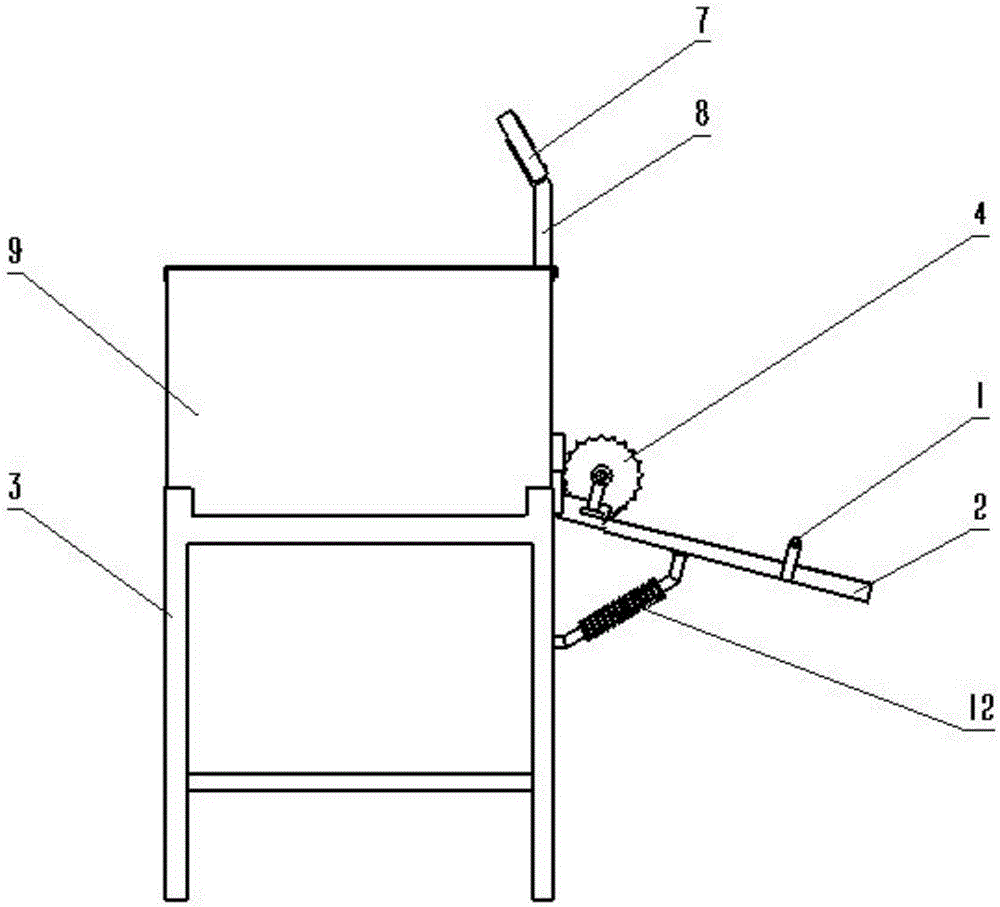

[0033] The steel ball counter based on single-chip microcomputer comprises mechanical device and counting control system; Described mechanical device is made up of support, box body, guide groove, frame bar, supporting rod, cross bar; Described counting control system is made up of core control module, It consists of a steel ball detection device, a steel ball blocking device, and a speed control device.

[0034] Such as figure 1 and image 3 As shown, the box body (9) is fixed on the bracket (3), and the bracket (3) is used to support the box body (9), and the upper part of the bracket (3) adopts a right-angle structure that can cooperate with the box body (9); The box body (9) is used to hold steel balls, the volume is 150L, and can hold steel balls of about 1 ton. The bottom of the box body (9) is provided with a slope (6), and the steel balls can slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com