Design method for improving machine tool machining precision

A technology of processing accuracy and design method, applied in computer control, comprehensive factory control, instrument, etc., can solve problems such as complexity, increased machine tool manufacturing cost, and unsatisfactory real-time processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

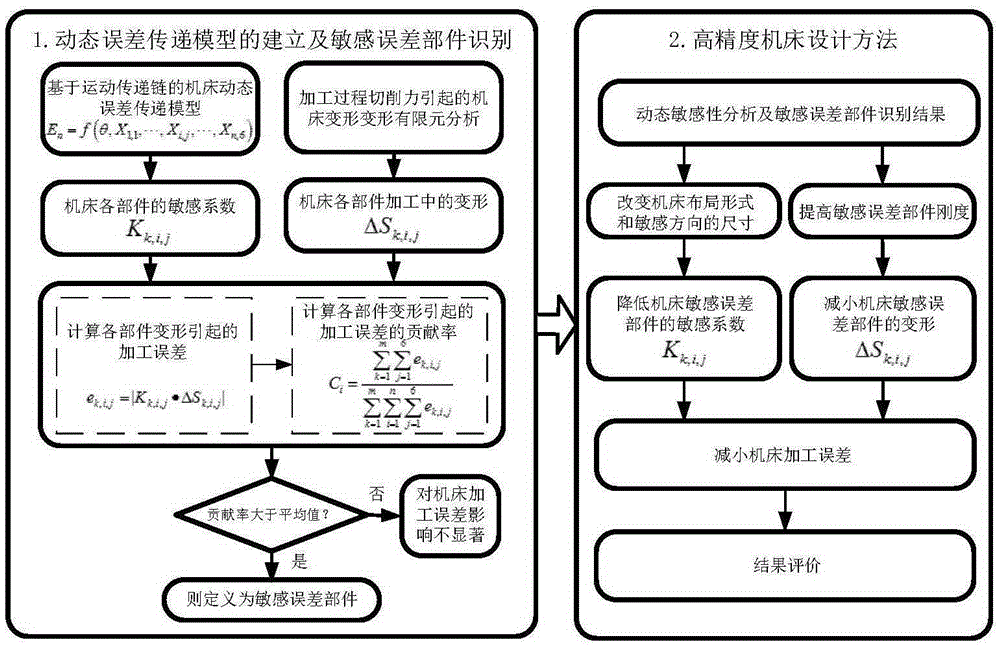

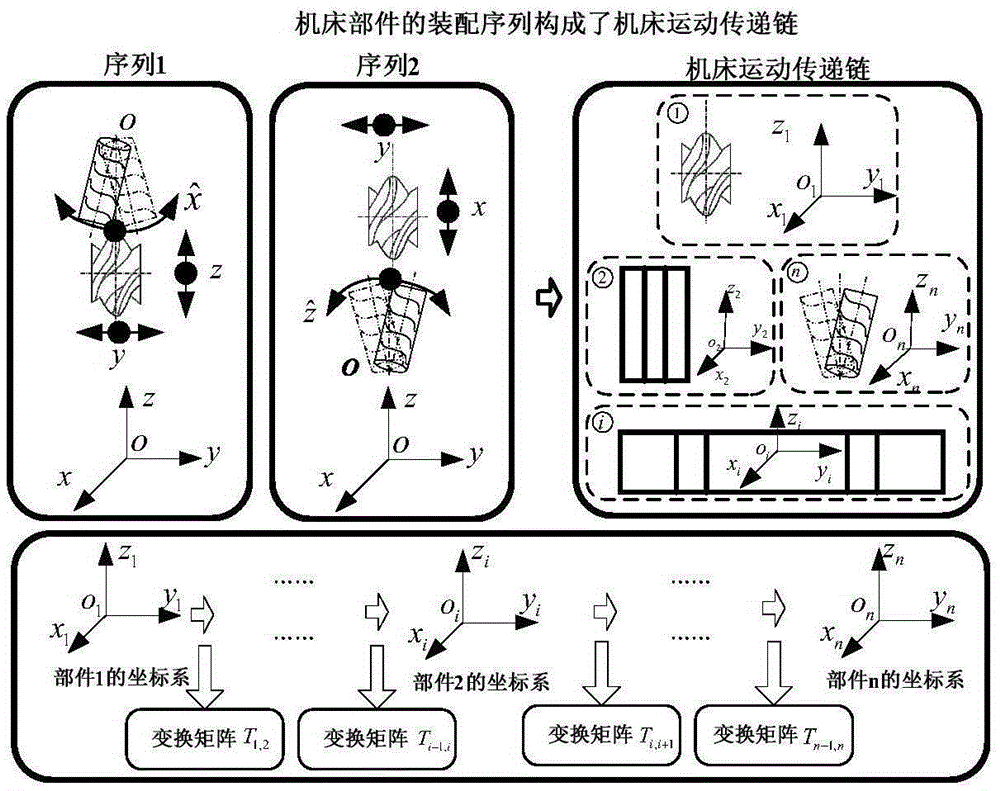

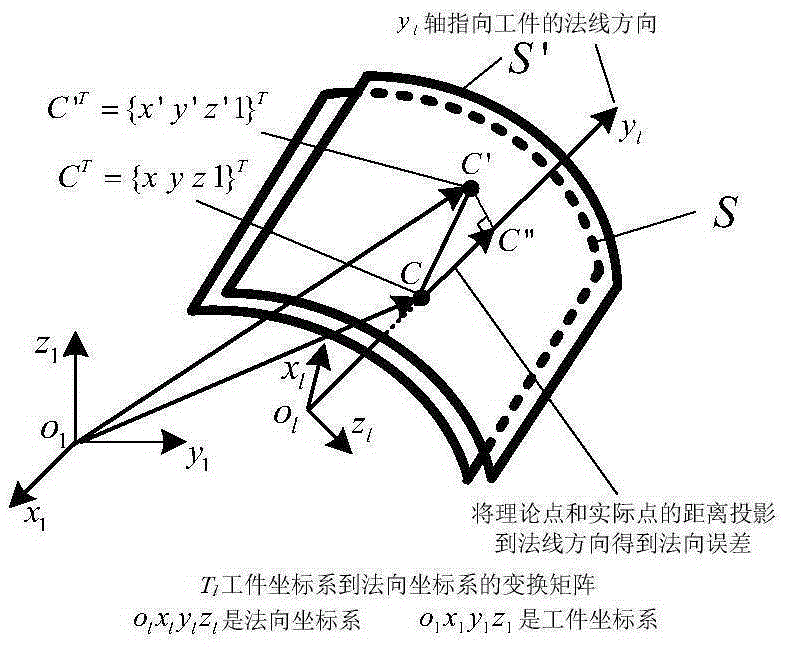

[0054] Such as figure 1 As shown, the present invention is a design method for improving the machining accuracy of machine tools, which includes two parts: the first part is the establishment of the dynamic error transfer model of the machine tool and the identification of sensitive error parts of the machine tool, and the second part is the implementation method for improving the machining accuracy of the machine tool. In order to analyze the influence of the deformation of the machine tool parts on the final machining accuracy and identify the sensitive error parts of the machine tool, it is necessary to establish a dynamic error transfer model of the machine tool according to the machine tool motion transfer chain. The machine tool components in the machine tool analyzed in the present invention at least include: bed, column, sliding slide, tool head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com