Laser Trimming Method

A laser resistance adjustment and resistance adjustment technology, applied in resistors, resistance manufacturing, electrical components and other directions, can solve the problems of non-repetition, low efficiency, low yield rate, etc., to improve resistance adjustment efficiency, avoid moisture entry, reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

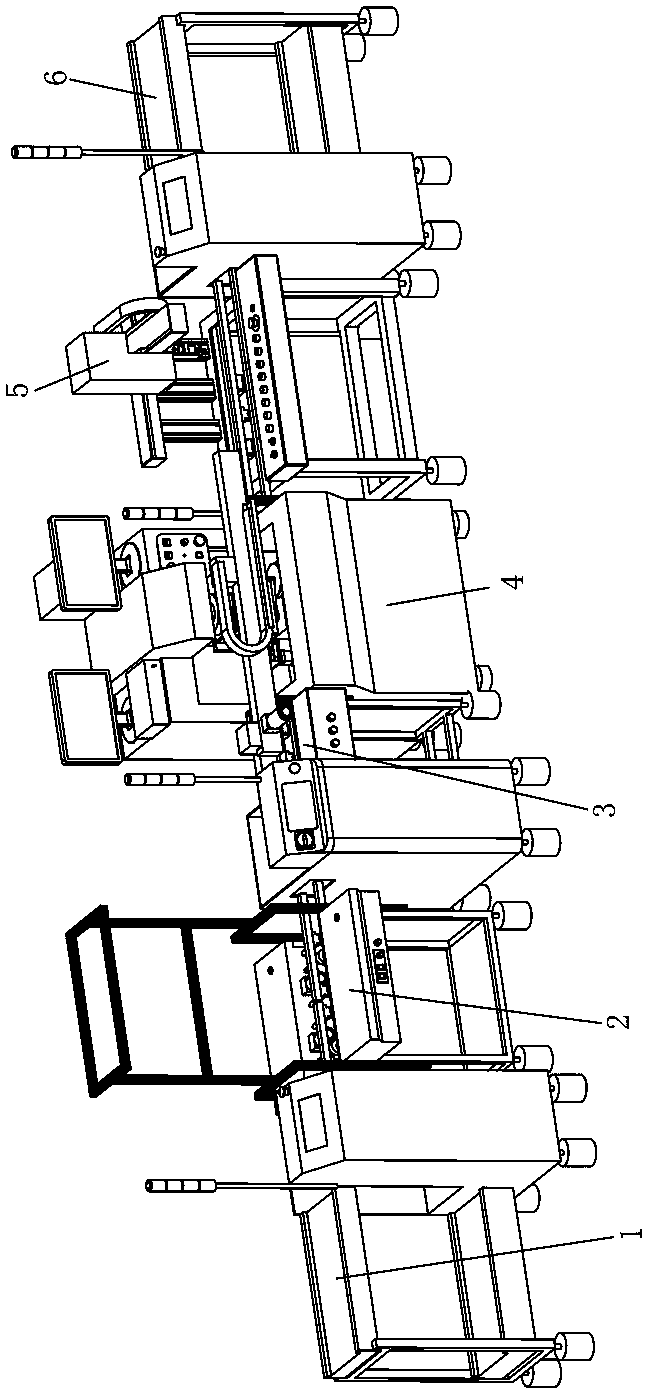

[0023] The present invention will be further described below in conjunction with accompanying drawing of description:

[0024] Such as figure 1 As shown, the present invention relates to a laser resistance trimming method, which includes the following steps:

[0025] (1) Preparation before resistance adjustment: take a large board containing several PCBAs to be adjusted, each PCBA is equipped with two resistances to be adjusted, place the large board at the beginning of the resistance adjustment processing line, and then turn on the resistance adjustment processing line;

[0026] (2) Conduction angle test: Transport the large board in step (1) from the initial section to the processing area of the resistance adjustment processing line, and perform clamping and positioning, and then conduct conduction on each PCBA to be adjusted on the large board Angle test to determine the resistance adjustment conditions of each PCBA to be adjusted;

[0027] (3) Laser cutting resistors:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com