Core-less winding machine

A wire winding machine and wire winding technology, applied in the direction of electrical components, etc., can solve the problems of cost increase, environmental pollution, etc., and achieve the effects of cost environmental protection, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

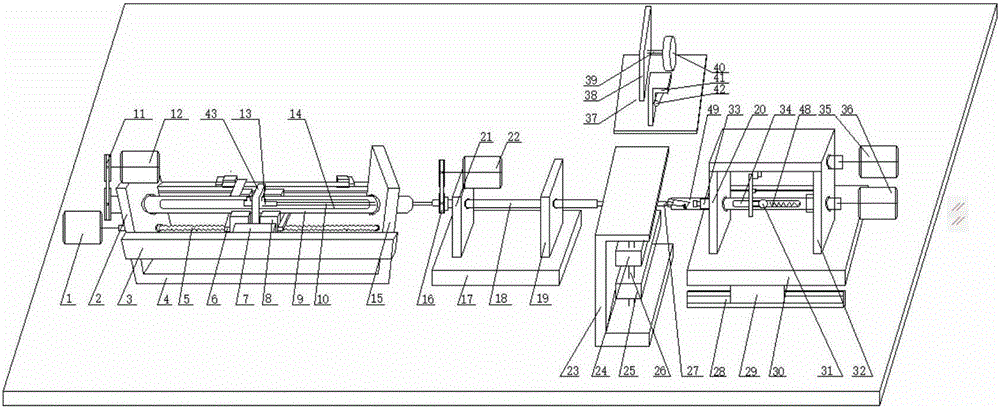

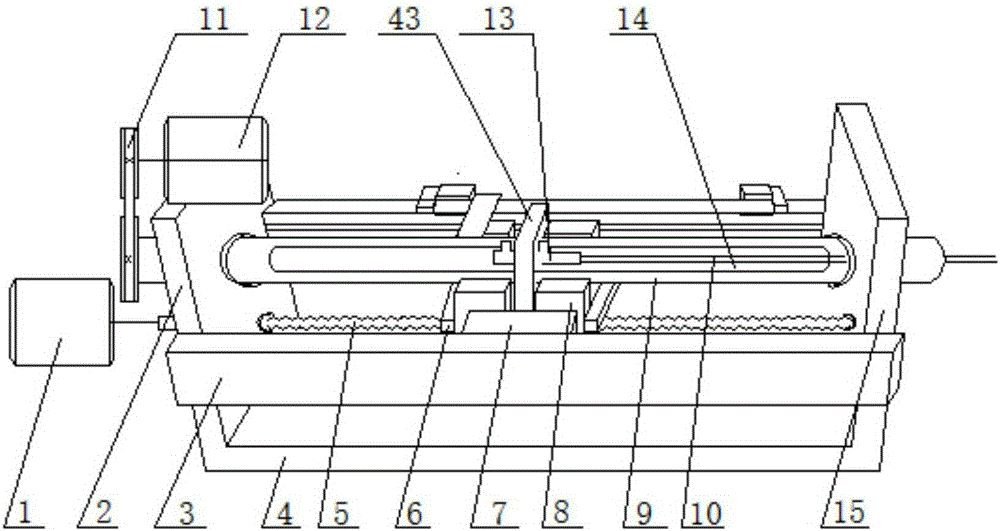

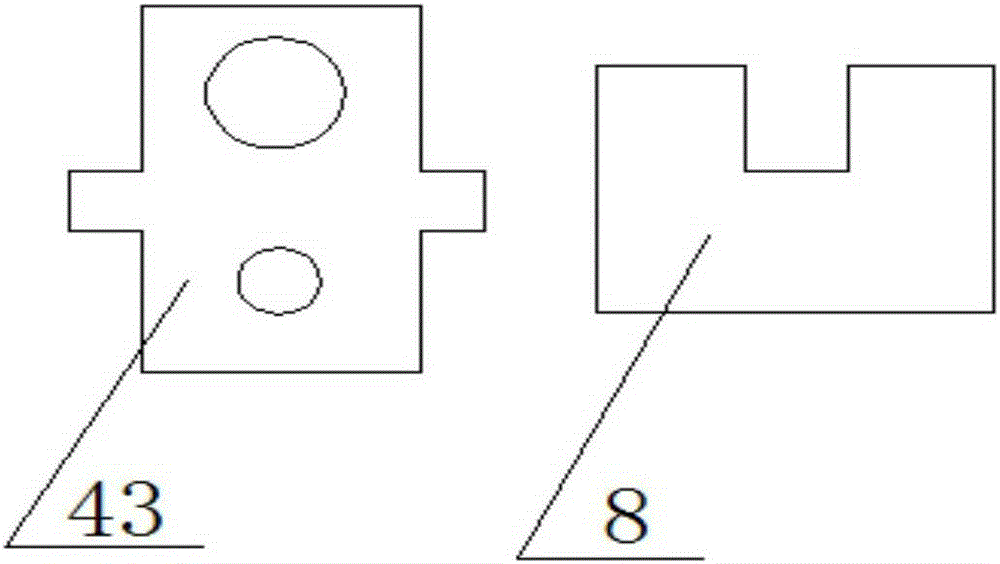

[0026] like Figure 1 to Figure 6 As shown, a coreless wire winding machine includes a wire winding mechanism, a wire cutting mechanism, a wire drawing mechanism and a wire feeding mechanism, and the wire winding mechanism, the wire cutting mechanism, the wire drawing mechanism and the wire feeding mechanism are all installed on the console; It is characterized in that the wire winding mechanism is arranged on the left side of the wire drawing mechanism, the wire cutting mechanism is arranged on the right front of the wire winding mechanism, the wire feeding mechanism is arranged directly opposite to the wire cutting mechanism, and the wire winding mechanism mainly includes a second A motor 12, the first motor is arranged on one end of the first support plate, the first support plate is divided into a left first support plate 2 and a right first support plate 15, and the left and right first support plates are respectively An upper first through hole and a lower first through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com