Electrode slice structure and battery module

A technology of electrode sheet structure and battery module, applied in battery pack parts, structural parts, active material electrodes, etc., can solve the problems of wasting man-hours, destroying joint strength, hindering high-frequency vibration, etc., so as to reduce costs and reduce damage Risk, effect of securing joint strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The electrode sheet structure and battery module according to the present invention will be described in detail below with reference to the accompanying drawings.

[0047] First, the structure of the electrode sheet according to the first aspect of the present invention will be described.

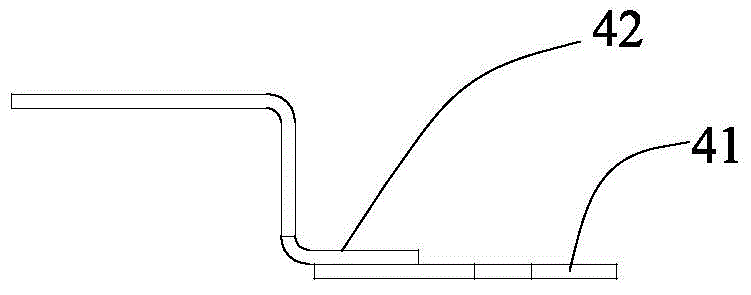

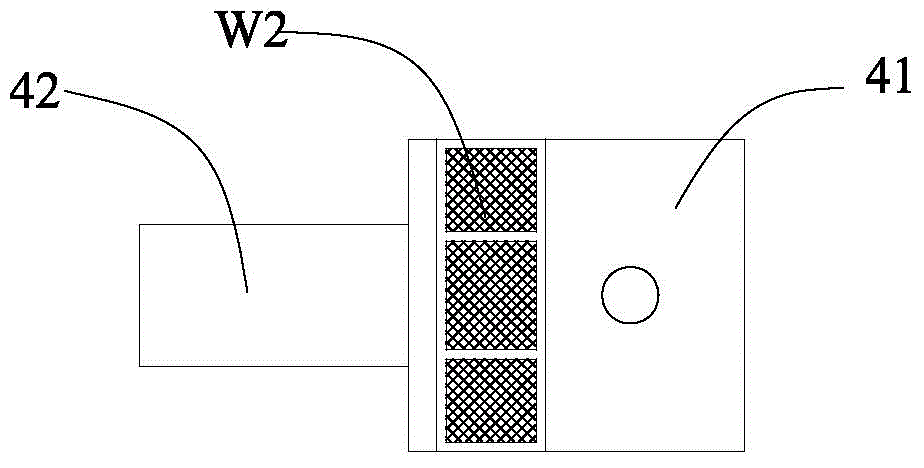

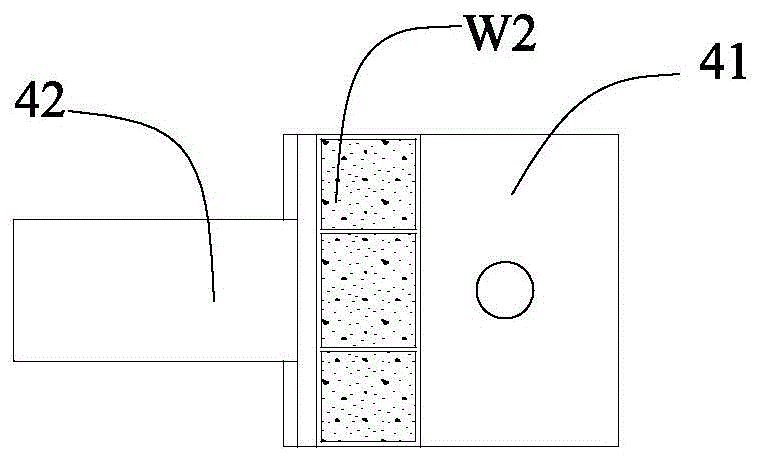

[0048] Before going into detail, it should be noted that the Figure 13-17 Among them, W1 indicates the welding area where the aluminum electrode sheet 41 is welded to the pole 11, W2 indicates the area where the aluminum electrode sheet 41 is in contact with the welding head (not shown) of the welding machine, and W4 indicates the copper electrode sheet 42 and the welding seat of the welding machine (not shown) the area of contact. refer to Figure 9 to Figure 18 , the electrode sheet structure 4 according to the present invention includes: an aluminum electrode sheet 41, which is disc-shaped, and is used to electrically connect with the pole 11 of the battery 1 of the battery m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com