Photocurable resin composition and image display device production method

一种光固化性树脂、图像显示装置的技术,应用在光固化性树脂组合物领域,能够解决保存稳定性降低、投资膨大等问题,达到改善形状维持性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0104] Embodiment 1~6, comparative example 1~4

[0105] The (meth)acrylate oligomer component, (meth)acrylate alkyl ester monomer component, plasticizer component (solid tackifier and liquid plasticizer component) in the compounding amount (parts by mass) shown in Table 1 ) and a photopolymerization initiator component are uniformly mixed to prepare a photocurable resin composition.

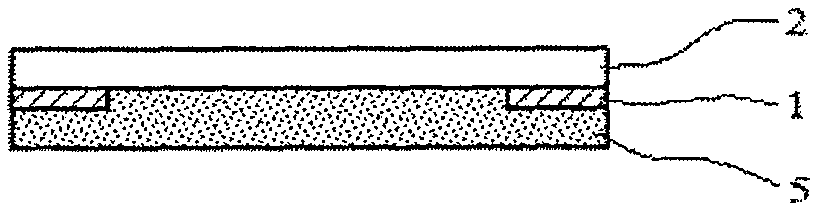

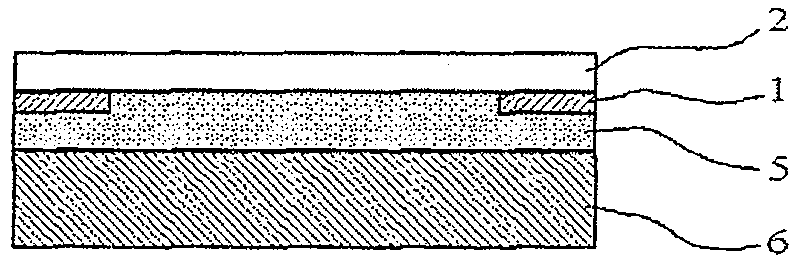

[0106] Next, this photocurable resin composition was sprayed over the entire surface of the glass plate using a slit resin dispenser to form a photocurable resin composition film with an average thickness of 200 μm.

[0107] Next, with respect to this photocurable resin composition film, an ultraviolet irradiation device (UVL-7000M4-N, manufactured by USHIOINC) was used so that the cumulative light intensity became 1000mJ / cm 2 、2500mJ / cm 2 、5000mJ / cm 2 or 7500mJ / cm 2 In the way of changing the irradiation time, the irradiation intensity is 200mW / cm 2 The ultraviolet rays are used to cure the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap