A wet electrostatic precipitator

A wet electrostatic precipitator and tubular technology, applied in the field of dust removal, can solve the problems of increasing the net flow area of flue gas and the specific dust collection area, increasing the area of the equipment and investment cost, increasing the selection of equipment, etc. The effect of dust removal and fog removal efficiency, long residence time, and investment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide a wet electrostatic precipitator, which has high efficiency of dust removal and mist removal, can adapt to occasions with large amount of flue gas pollution, and has a small footprint and can reduce investment costs.

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

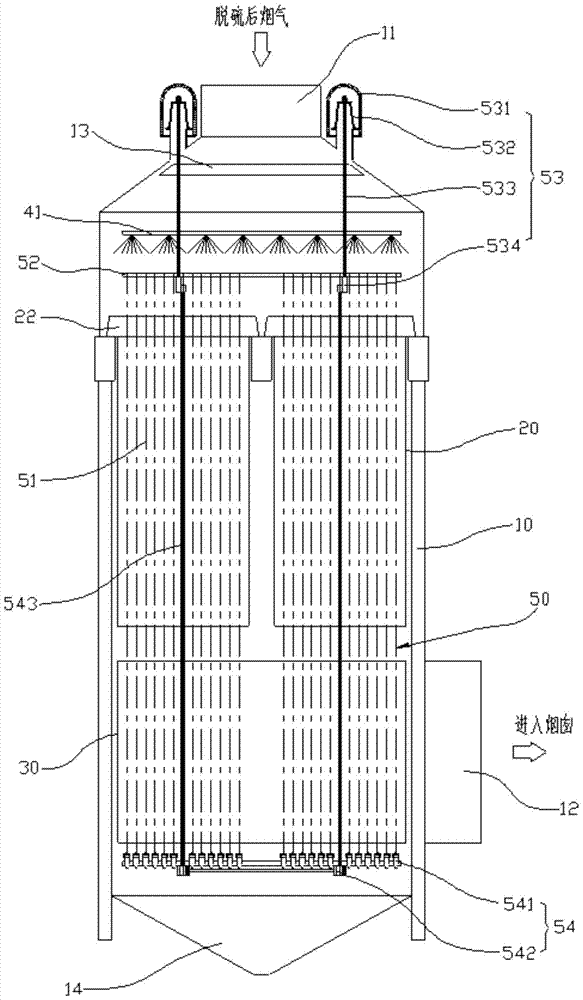

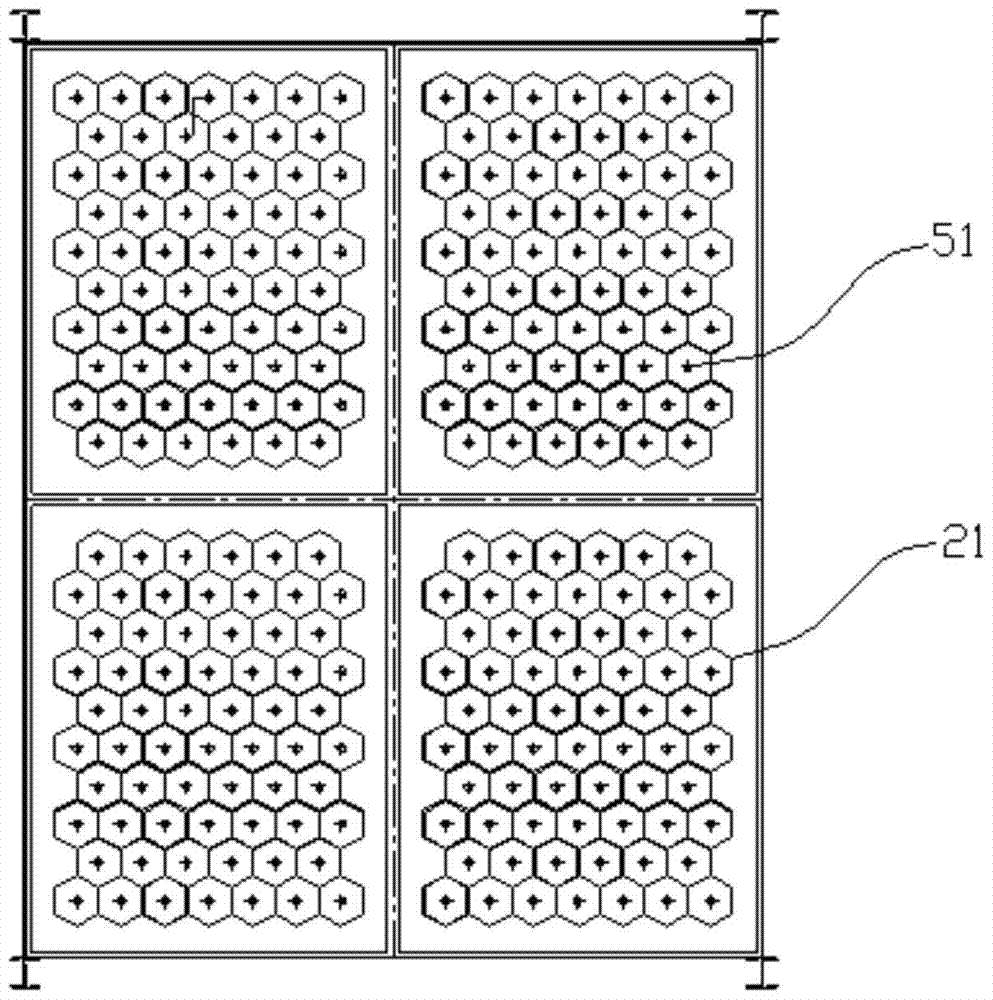

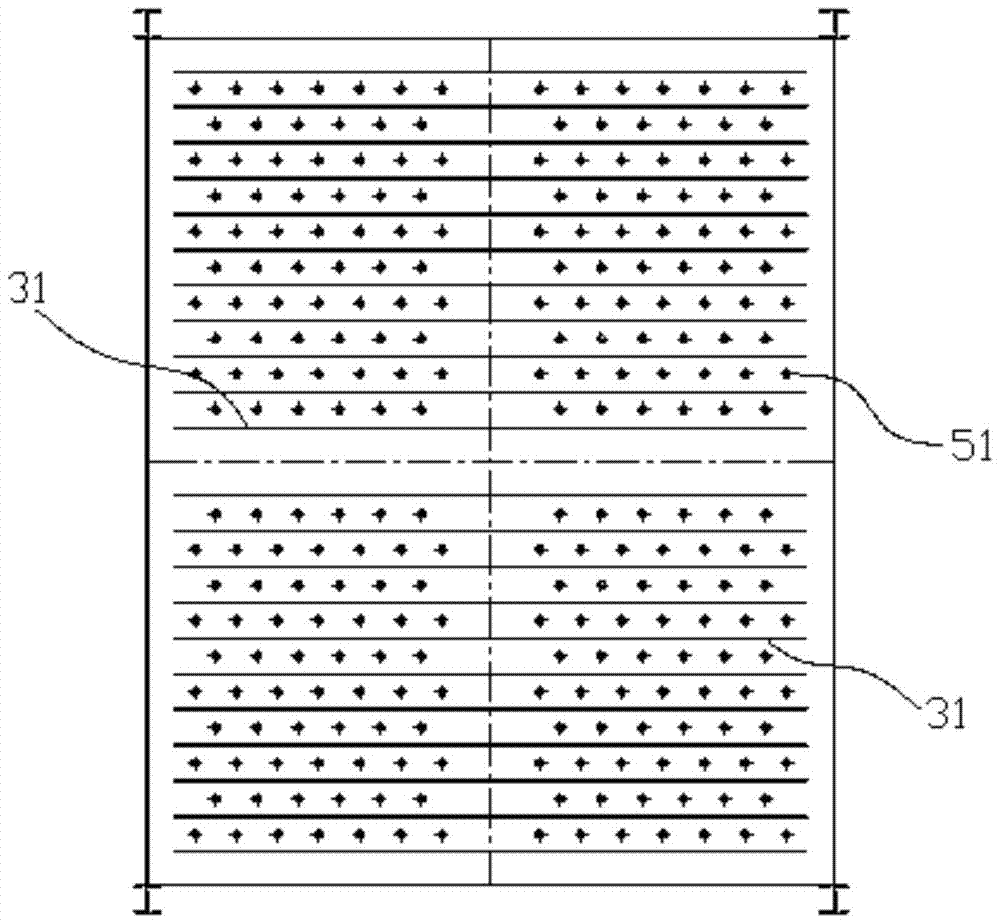

[0036] Please refer to figure 1 , figure 1 It is a sectional view of a specific embodiment of the wet electrostatic precipitator provided by the present invention.

[0037] In this embodiment, the wet electrostatic precipitator provided by the present invention includes a casing 10, the top of which is provided with an inlet horn 11 for the flue gas after desulfurization to enter, and the lower side of the casing 10 has a The flow port through which air flows ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com