A mineral processing device

A processing device, technology of mineral products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing and embodiment describe in detail:

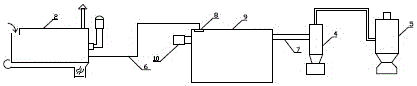

[0060] Such as figure 1 As shown, the first mineral product processing device of the present invention includes a dryer 2, a wind separator 9, a material receiving container 4 and a dust collector 5, and the dryer 2 sends the dried ore to the wind through a conveyor belt 6. The feed port 8 of the separator 9, the air separator 9 screens out the ore, the air separator 9 sends the remaining tailings through the pipeline 7 to the receiving container 4, and the dust discharged from the receiving container 4 is sent to the dust collector 5 processes, and air separator 9 is used as material selector here.

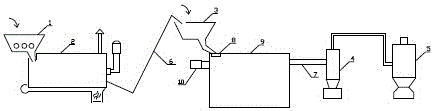

[0061] Such as figure 2 As shown, the second mineral product processing device of the present invention includes a dryer 2, a first distributing machine 1, a second distributing machine 3, a winnowing machine 9, a material receiving container 4 and a dust remover 5, and the first distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com