Production method of rectangular aluminum alloy pipe

A production method and technology for rectangular tubes, which are applied in the production field of aluminum alloy rectangular tubes, can solve the problems of metal waste, low production efficiency, and poor dimensional accuracy, and achieve the effects of overcoming poor dimensional accuracy, easy implementation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

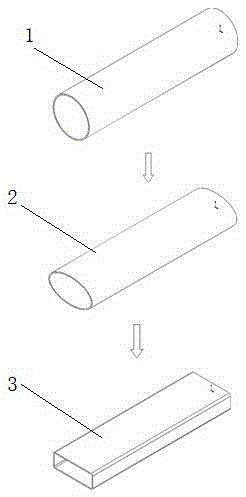

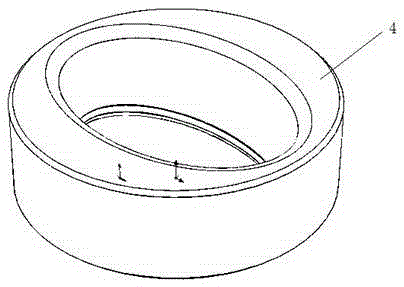

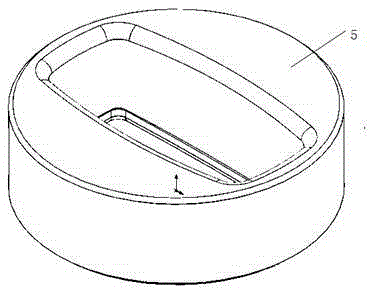

[0025] Embodiment, a kind of production method of aluminum alloy rectangular pipe, see figure 1 , figure 2 , image 3 , the process route is: round tube wool 1→wool annealing→transitional stretching into oval tube 2→forming and stretching into rectangular tube 3→stretching straightening→expanding tube→stretching straightening→cutting into finished products, sampling→packaging , storage.

[0026] The rectangular tube 3 is an aluminum alloy tube with a rectangular (or similar to rectangular) cross section.

[0027] The finished product in this embodiment is a large-scale rectangular thin-walled tube, that is, the diagonal length of the rectangular tube is ≥ 200 mm, the wall thickness is ≤ 10 mm, and the aspect ratio of the rectangular tube is ≥ 2. For example: 230×100×6, 240×100×5, 285×100×6 and other specifications of rectangular tubes.

[0028] Transition stretching is to stretch the round tube wool 1 into an elliptical tube 2 , and forming stretching is to stretch the el...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap