Nuclear power plant unipolar magnetic control band electrode electroslag surfacing method and device

A technology for electroslag surfacing and nuclear power plants, applied in the field of unipolar magnetically controlled strip-polar electroslag surfacing welding methods and devices in nuclear power plants, which can solve the problems of affecting the accessibility of welding torches, collisions, and magnetic control modules affecting welding accessibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

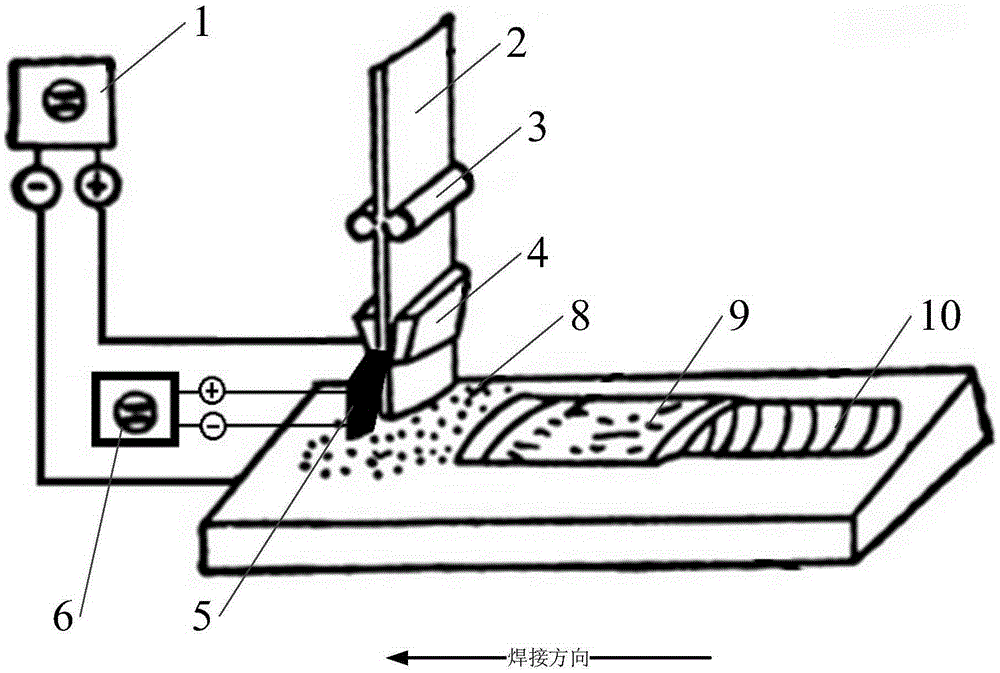

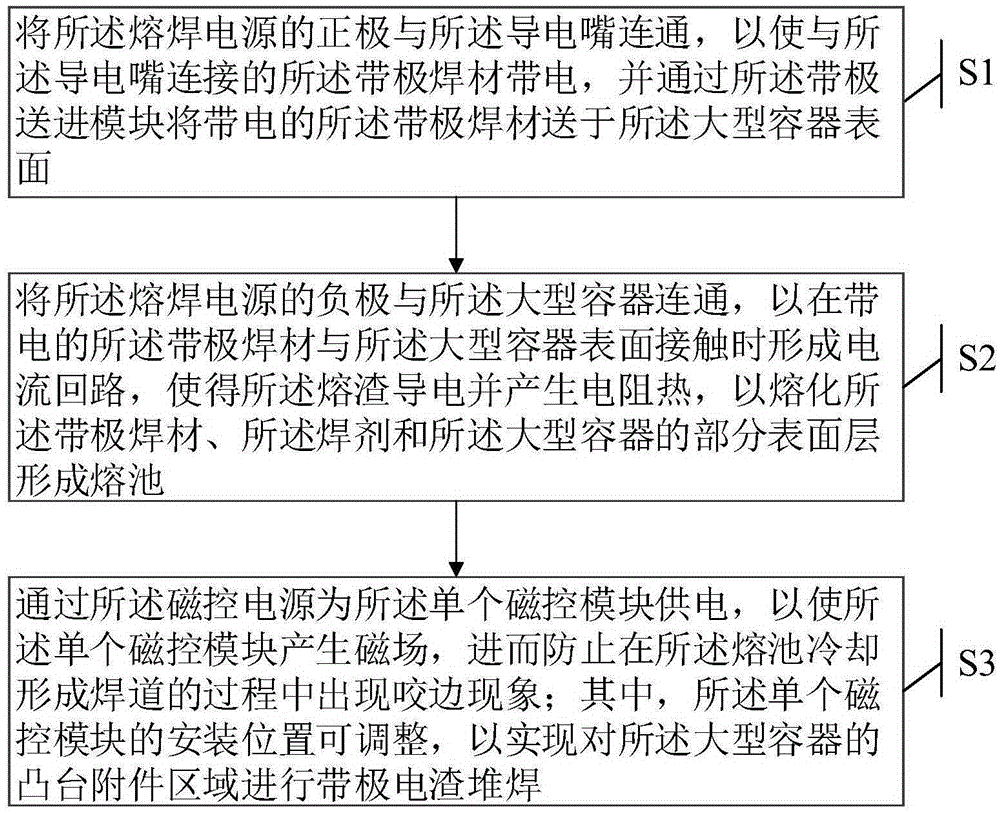

[0036] The embodiment of the present invention provides a method for unipolar magnetron electroslag surfacing welding with poles in a nuclear power plant, which is applied to a magnetron electroslag surfacing device for surfacing corrosion-resistant layers for large vessels in nuclear power plants. Please refer to figure 1, the strip-electroslag surfacing device includes: welding power supply 1, strip welding material 2, strip-feeding module 3, conductive tip 4, single magnetron module 5 and magnetron power supply 6; large container 7 is laid on the surface There are flux 8 and slag 9; such as figure 2 As shown, the strip electroslag surfacing method may further comprise the steps:

[0037] S1. Connect the positive electrode of the welding power source 1 with the contact tip 4, so that the strip welding material 2 connected to the contact tip 4 is charged, and the charged electrode is fed into the module 3 through the strip electrode The strip welding material 2 is sent to t...

Embodiment 2

[0048] Based on the same inventive concept, please refer to figure 1 , the embodiment of the present invention also provides a nuclear power plant unipolar magnetron strip electroslag surfacing device, including: fusion welding power supply 1, strip welding material 2, strip feeding module 3, conductive tip 4, magnetron module 5 and a magnetron power supply 6; the electroslag surfacing device with poles is used for overlaying the corrosion-resistant layer for the large container 7 of the nuclear power plant, and the surface of the large container 7 is covered with flux 8 and slag 9, wherein,

[0049] The strip feeding module 3 is connected to the strip welding material 2, and is used to send the strip welding material 2 to the surface of the large container 7 during the surfacing process;

[0050] The conductive tip 4 is arranged on the strip welding material 2, and is connected to the positive pole of the welding power source 1, and is used to charge the strip welding materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com