Ultrafast laser machining device for blade punching based on cold machining mode

An ultra-fast laser and processing device technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large electrode loss, high cost, low production efficiency, etc., and achieve high processing efficiency, low cost, and space. narrowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

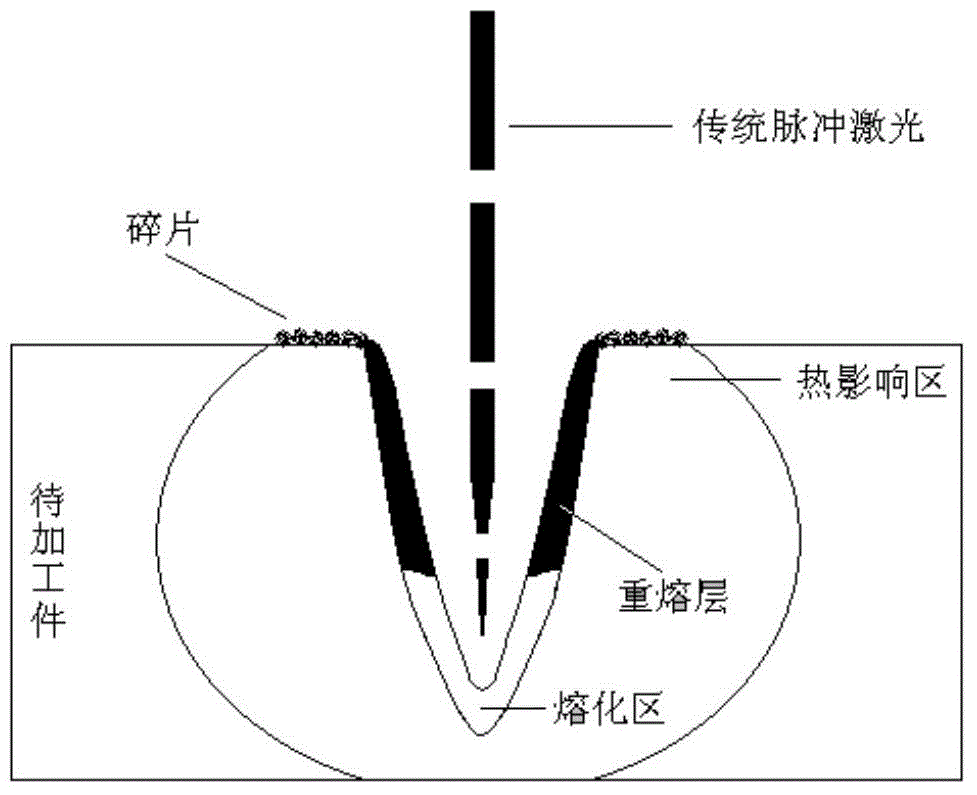

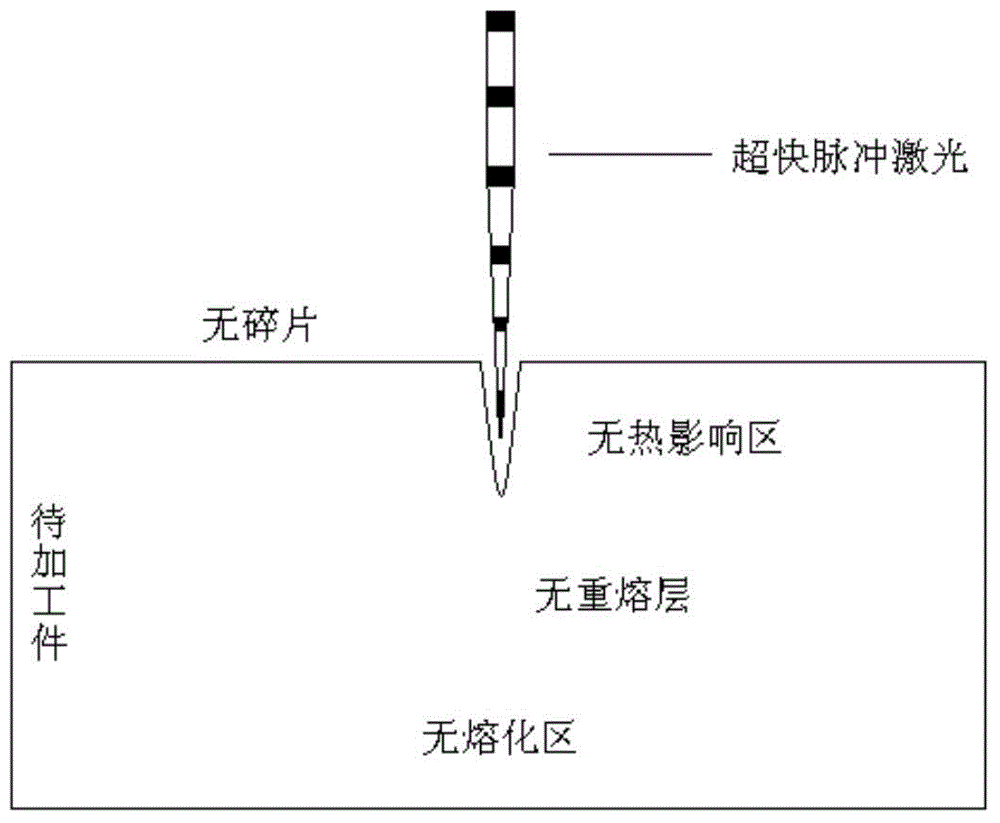

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described now in conjunction with accompanying drawing.

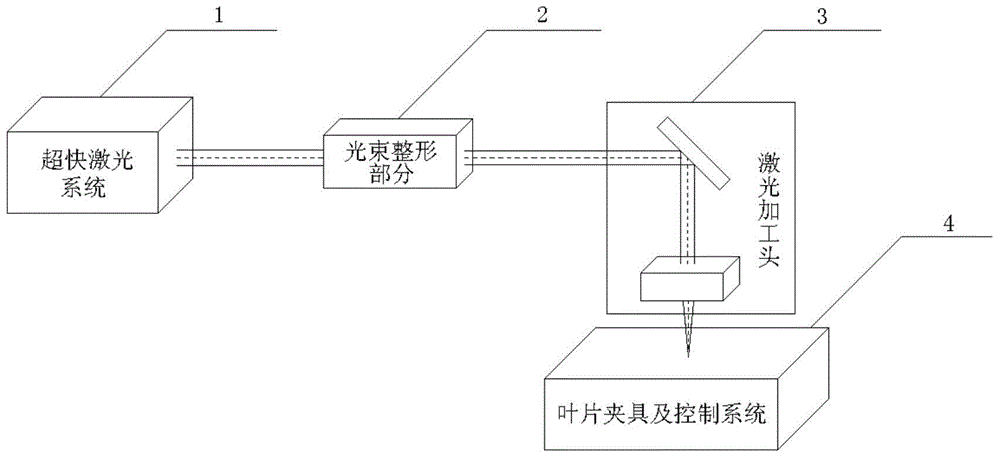

[0019] Ultrafast lasers are pulsed lasers with very short pulse widths, such as picosecond and femtosecond lasers. like figure 2 As shown, the ultrafast laser processing device for blade drilling based on cold processing includes: an ultrafast laser system 1 , a beam shaping part 2 , a laser processing head 3 , a blade fixture and a control system 4 . The ultrafast laser system 1 can be a picosecond or femtosecond laser system; the beam shaping part 2 includes several lenses and optical elements; the laser processing head 3 includes the reflection device above and the following focusing lens; the blade fixture and control system 4 are used to precisely adjust the position of the blade. The reflection device is a reflection mirror or a pair of scanning galvanometers in the XY direction, and the blade fixture and control system 4 is a seven-degree-of-freedom manipulator or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com