Novel compressor rotor blade groove machining clamping tool

A compressor rotor and blade groove technology, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of endangering the life safety of operators, time-consuming and laborious clamping reliability, affecting product qualification rate, etc. Achieve semi-automatic control and avoid the effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

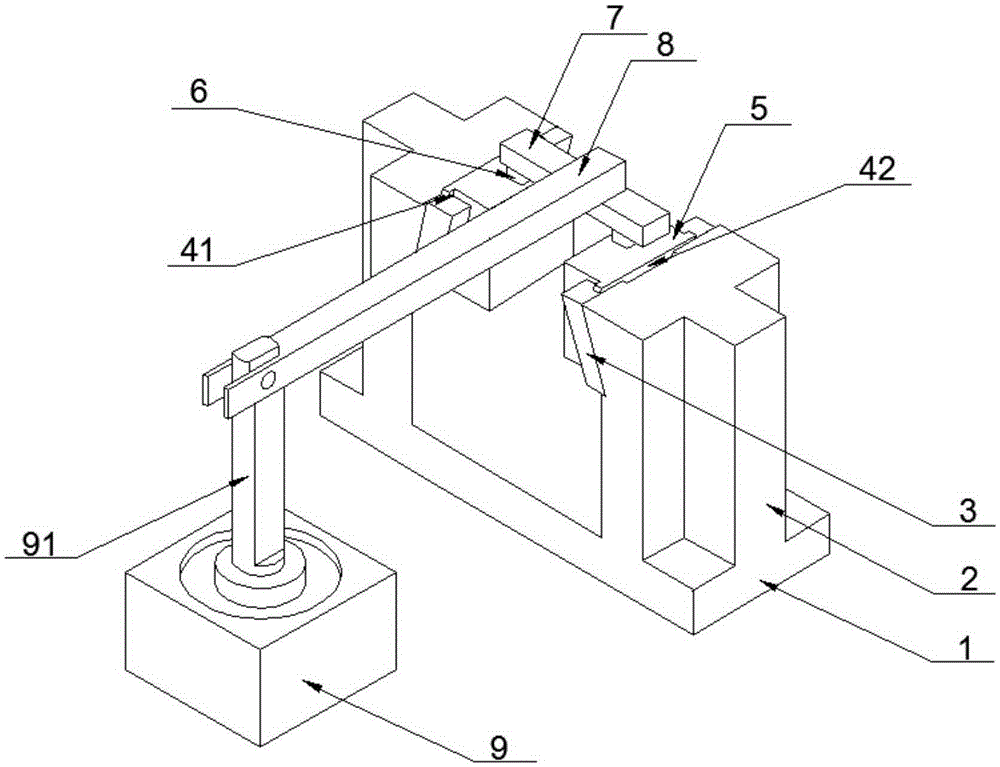

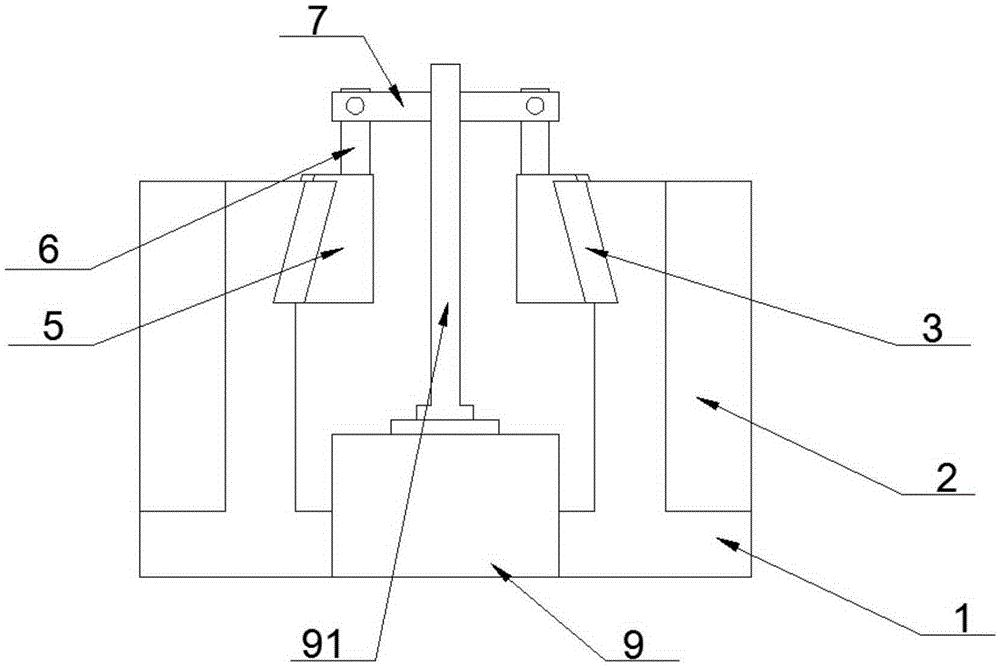

[0014] Such as figure 1 with figure 2 As shown, a new type of compressor rotor blade groove processing and clamping tool includes a clamping device, and the clamping device includes a base 1, and two clamping blocks 2 are arranged in parallel on the base 1, and the two described The clamping blocks 2 are arranged facing each other, and the two clamping blocks 2 are perpendicular to the base 1, and the opposite side tops of the two clamping blocks 2 are fixedly installed with clamping slide mounting seats 3 respectively. A first guide chute 41 and a second guide chute 42 are respectively provided on the clamping slide mounting seat 3, and a clamping slide 5 is respectively arranged in the first guide chute 41 and the second guide chute 42, so that Both the first guide chute 41 and the second guide chute 42 are chute whose upper ends are inclined inwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com