Skylight truss hanger

A skylight frame and hanger technology, which is applied in the field of hoisting engineering construction, can solve the problems of easy inclination, reduce the risk of high-altitude operation, and affect the assembly accuracy, and achieve the effects of ensuring the assembly accuracy, solving the difficulty of positioning, and reducing the risk of high-altitude operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

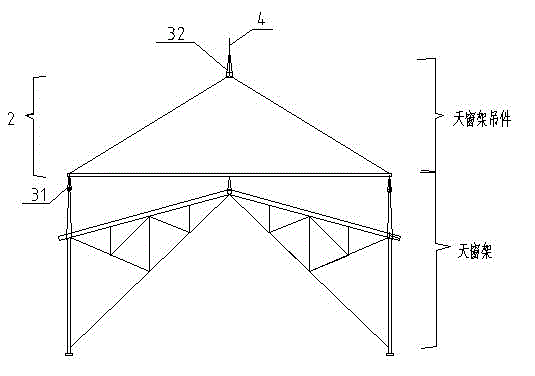

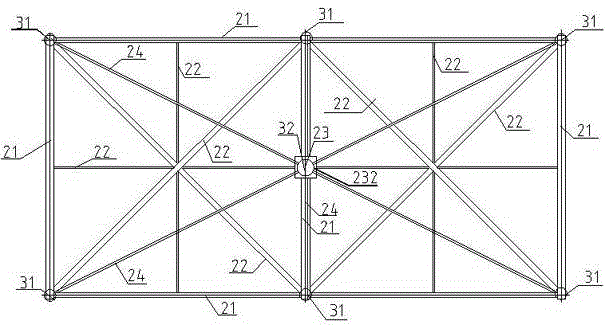

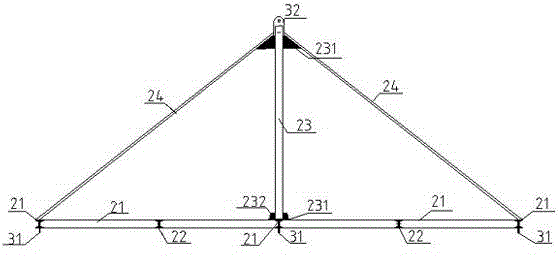

[0022] Such as Figures 1 to 4 As shown, the present invention is a skylight frame hanger, which includes a skylight frame assembled in twos and a skylight frame hanger body 1, and a steel truss 2 includes a shaped steel girder 21, a shaped steel support 22, a steel pipe vertical rod 23 and an angle steel tie rod 24. There are upper lifting lugs on the top of the steel pipe pole, which are connected with the lifting equipment. There are six angle steel tie rods in the four corners and the middle part of the steel main girder, and one lifting lug is set at the bottom of the main beam where the angle steel tie rods are installed. 31, connect the skylight frame through the lug 31 and the wire rope 4.

[0023] The specific steps are as follows: Step 1: Splicing and assembling the assembled single skylight frames in pairs on the ground; Step 2: The main girders are made of 20 I-beams and connected into a whole by welding, and 10# I-beams are used between the main girders. The cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com