A milling device

A technology of milling and digging and hydraulic motor, which is applied in the field of shield tunneling equipment that expands the function of construction machinery, can solve the problems of high performance requirements of hydraulic motor and reducer, low transmission efficiency of parallel shaft reducer, and difficulty in maintenance and repair. Ease of maintenance and repair, improved energy usage, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

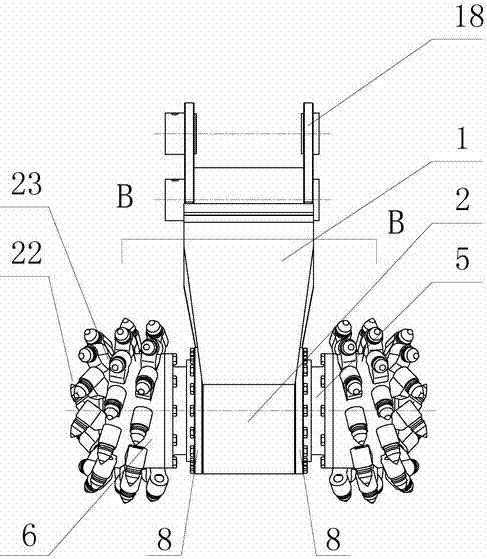

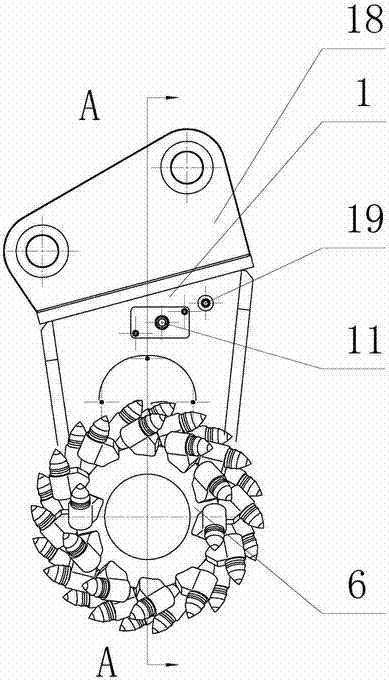

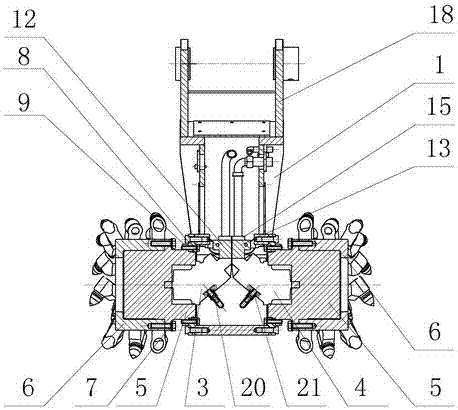

[0027] figure 1 , figure 2 , image 3 Among them, there is a central tube 2 at the lower part of the frame 1; the left hydraulic motor 3 and the right hydraulic motor 4 are installed in the central tube 2; the first overflow valve 12 is installed on the mounting surface of the left hydraulic motor 3; the second overflow valve 13 is installed on the right 4 mounting surfaces for hydraulic motors. The oil inlet and the oil outlet of the left hydraulic motor 3 are respectively connected with the oil inlet and the oil outlet of the first overflow valve 12; the oil inlet and the oil outlet of the right hydraulic motor 4 are respectively connected with the second overflow valve 13 The oil inlet and the oil outlet are connected; the main oil inlet 10, the main oil return port 11, and the oil discharge port 19 are arranged on the frame 1; one end of the main oil inlet pipe 14 is connected to the main oil inlet 10 on the frame 1 , the other end is connected to the oil inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com