Upper slewing body for use in construction machine

一种工程机械、回转体的技术,应用在载货车的上部结构、上部结构、车辆部件等方向,能够解决破坏、外侧支柱倒塌、驾驶室易变形等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

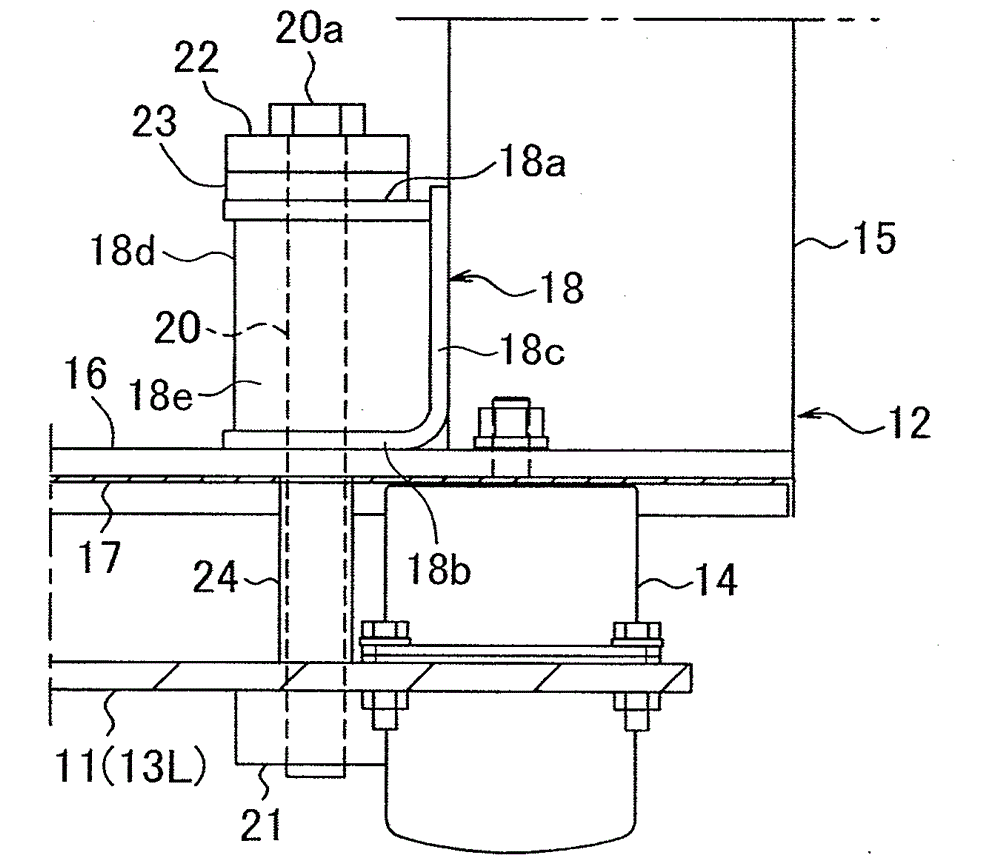

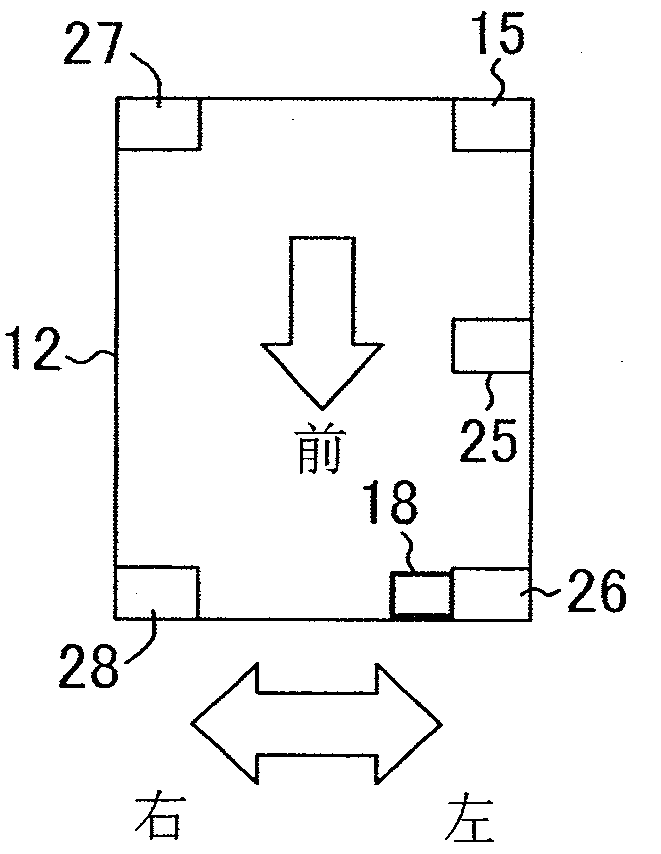

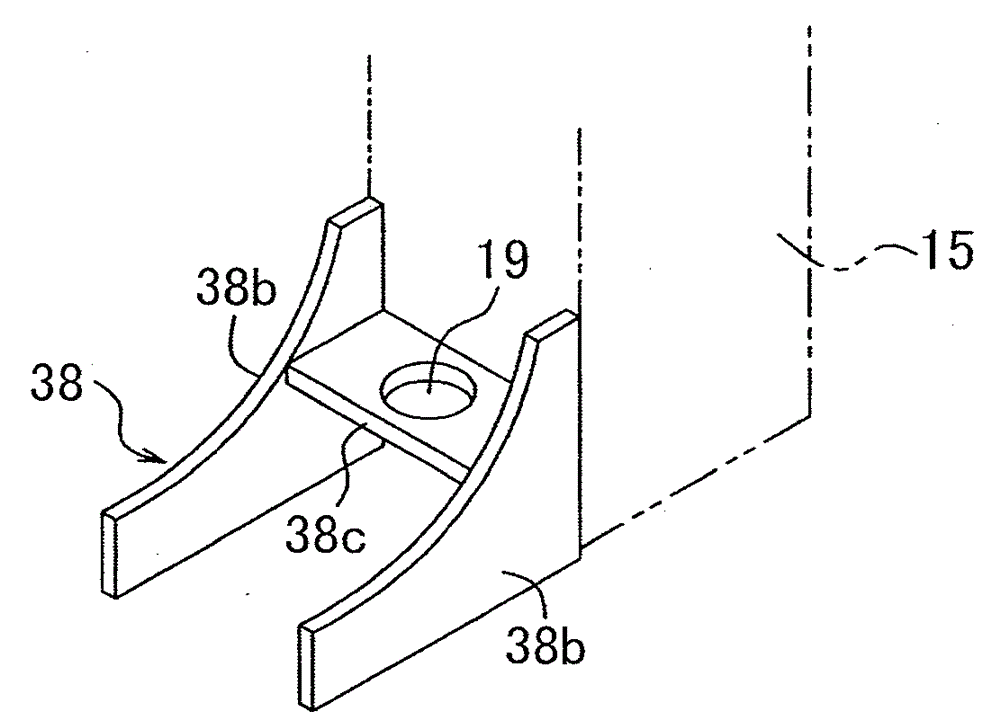

[0022] Embodiments of the present invention will be described with reference to the drawings.

[0023] Before describing the embodiments of the present invention, in order to clarify its features, first Figure 9 and Figure 10 The upper revolving body of the comparative example shown will be described.

[0024] Figure 9 The upper slewing body shown includes: an upper frame 1 , a driver's cab 2 , and multiple anti-vibration supports 4 . The upper frame 1 has a left side platform 3L corresponding to the left side and a right side platform 3R corresponding to the right side. The cab 2 is disposed on one of the left side and the right side. Hereinafter, the "front-rear direction" and "left-right direction" of the upper swing body related to the comparative example and the embodiment described later are all referred to as Figure 9 The cab shown is arranged on the left side of the upper frame ( Figure 9 Middle is the situation above the left platform 3L) as the premise.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com