A method for installing wall panels

An installation method and wall panel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of high cost, time-consuming and laborious, low precision, etc., and achieve the effects of low production cost, fast installation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

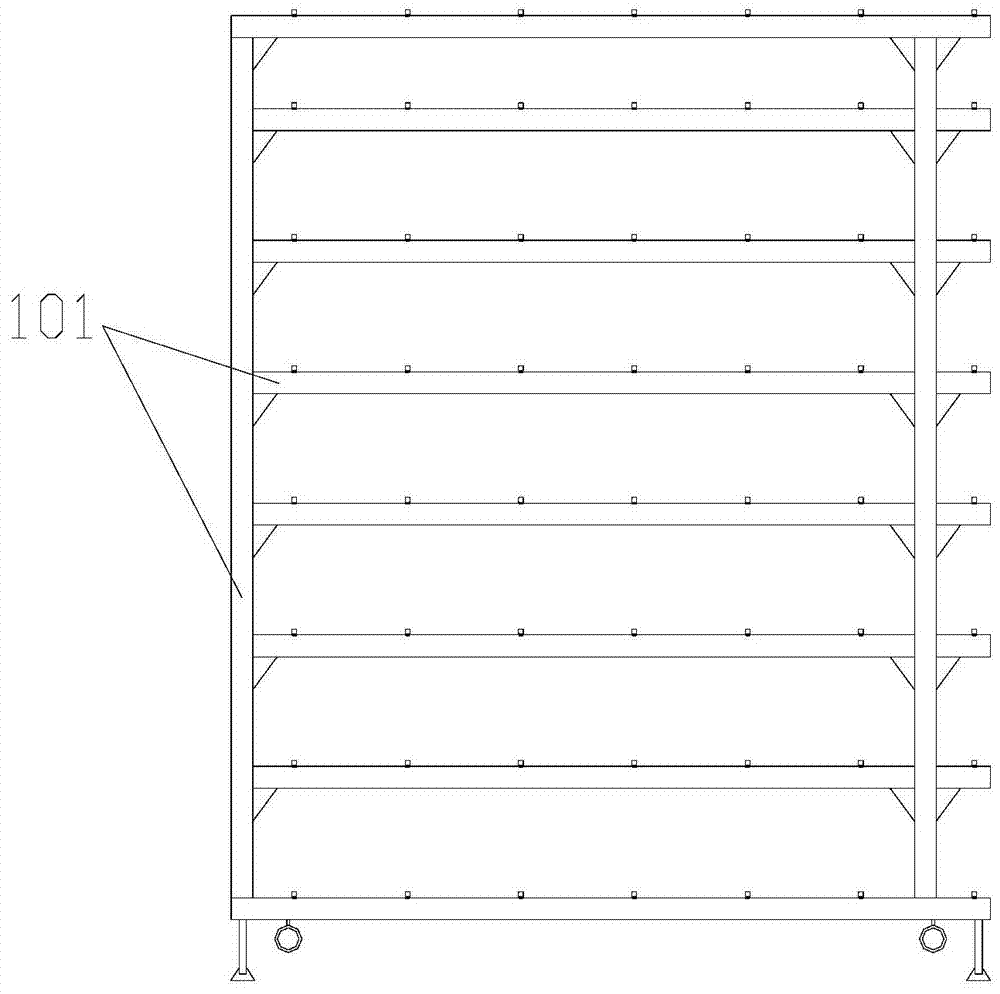

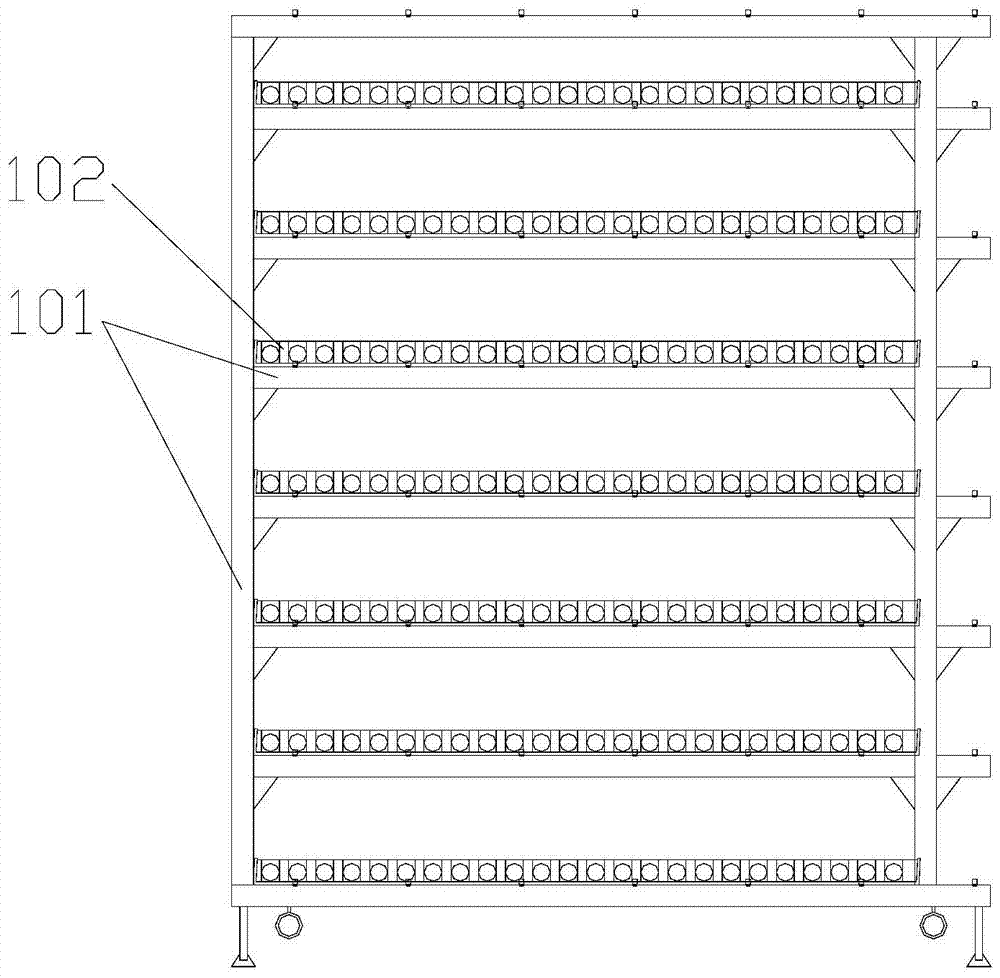

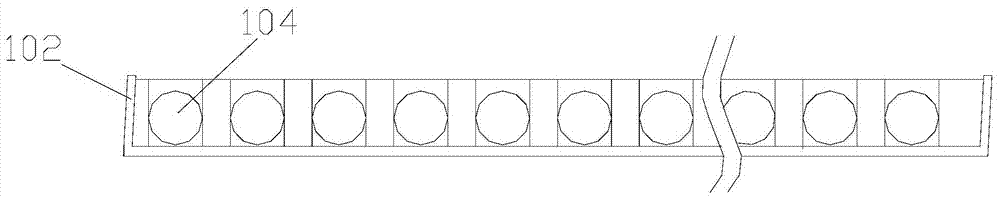

[0021] A method of installing a wall panel, the first step is to install the frame body, please refer to Figures 1 to 4 , the above-mentioned frame body includes a frame 101 surrounded by aluminum profiles and a horizontal frame 102. Specifically, the first step is to assemble the aluminum profiles into a frame 101 of the required size according to the area of the wall to be installed on the wall, and close to it. The wall is placed, and then a group of horizontal frames 102 arranged in parallel up and down are installed inside the frame 101, and a group of grooves 103 for socket connectors are provided on the side of the horizontal frame 102 close to the wall.

[0022] Then install the fittings, see Figures 5 to 6 , the connector includes a first mounting plate 1 that fits with the wall, a threaded rod 2 that is threaded with the first mounting plate 1, a second mounting plate 3 fixed on the other end of the threaded rod 2, and a gap with the second mounting plate 3 A th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com