Threaded-connection square steel pipe column and construction method

A technology of threaded connection and construction method, applied in the directions of columns, pillars, piers, etc., can solve the problems of low welding efficiency and difficult to guarantee welding quality, and achieve the effect of reducing the technical level and overcoming low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

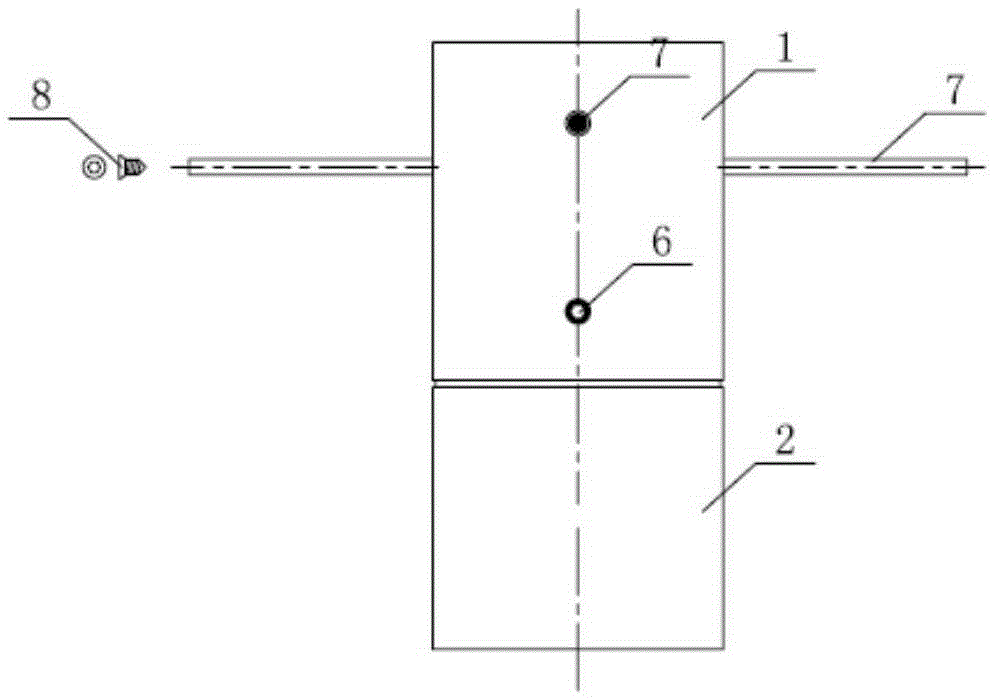

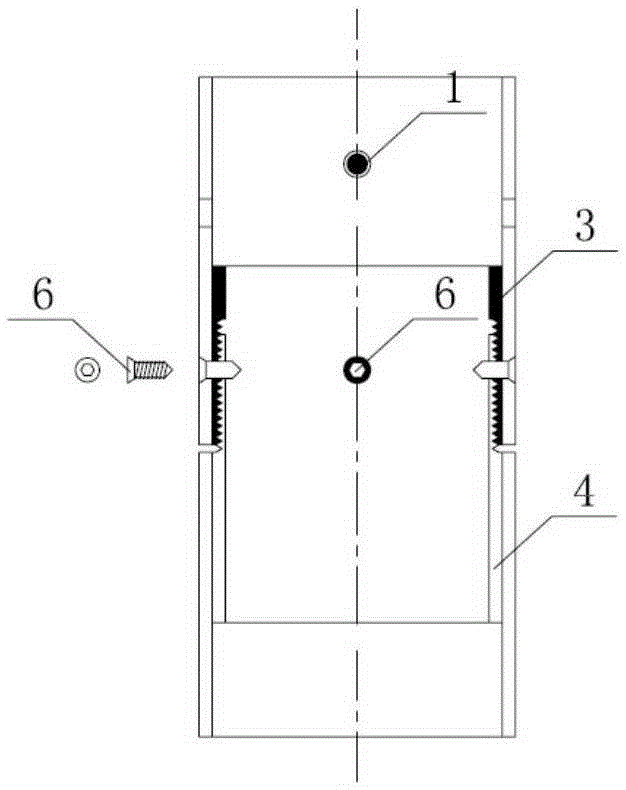

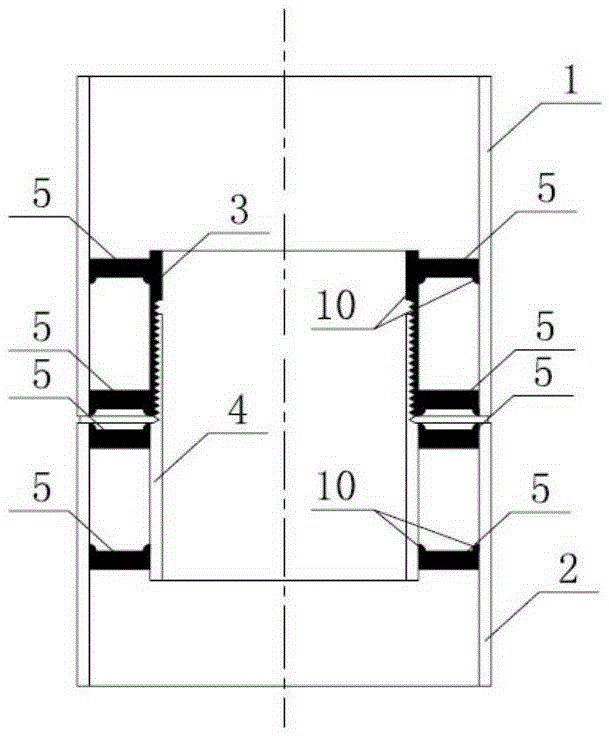

[0032] Such as figure 1 As shown, the thread splicing node of the square steel pipe column includes the upper square steel pipe column 1 and the lower square steel pipe column 2 to be spliced. Such as figure 2 and image 3 As shown, first in the factory, the upper square steel pipe column 1 and the upper round steel pipe splicing section 3 provided with internal threads are welded and connected at the tangent position with a fillet weld 9, and the height of the weld seam is not less than the wall thickness of the square steel pipe. The connecting plate 5 is used to weld the upper square steel pipe column 1 and the upper round steel pipe splicing section 3 provided with internal thread through the welding joint 10 of the connecting plate. The lower square steel pipe column 2 and the lower circular steel pipe splicing section 4 with internal thread are welded at the tangent position with fillet weld 9, and then the connecting plate 5 is used to connect the lower square steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com