A Grain Retaining Structure Used for One-piece Steel Structure Bulk Flat Storehouse

A steel structure, one-story warehouse technology, applied in the field of grain storage one-story warehouse, can solve the problems of increased cost, prolonged construction period, difficult installation, etc., and achieves the effect of optimizing the transmission path, improving the assembly efficiency, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

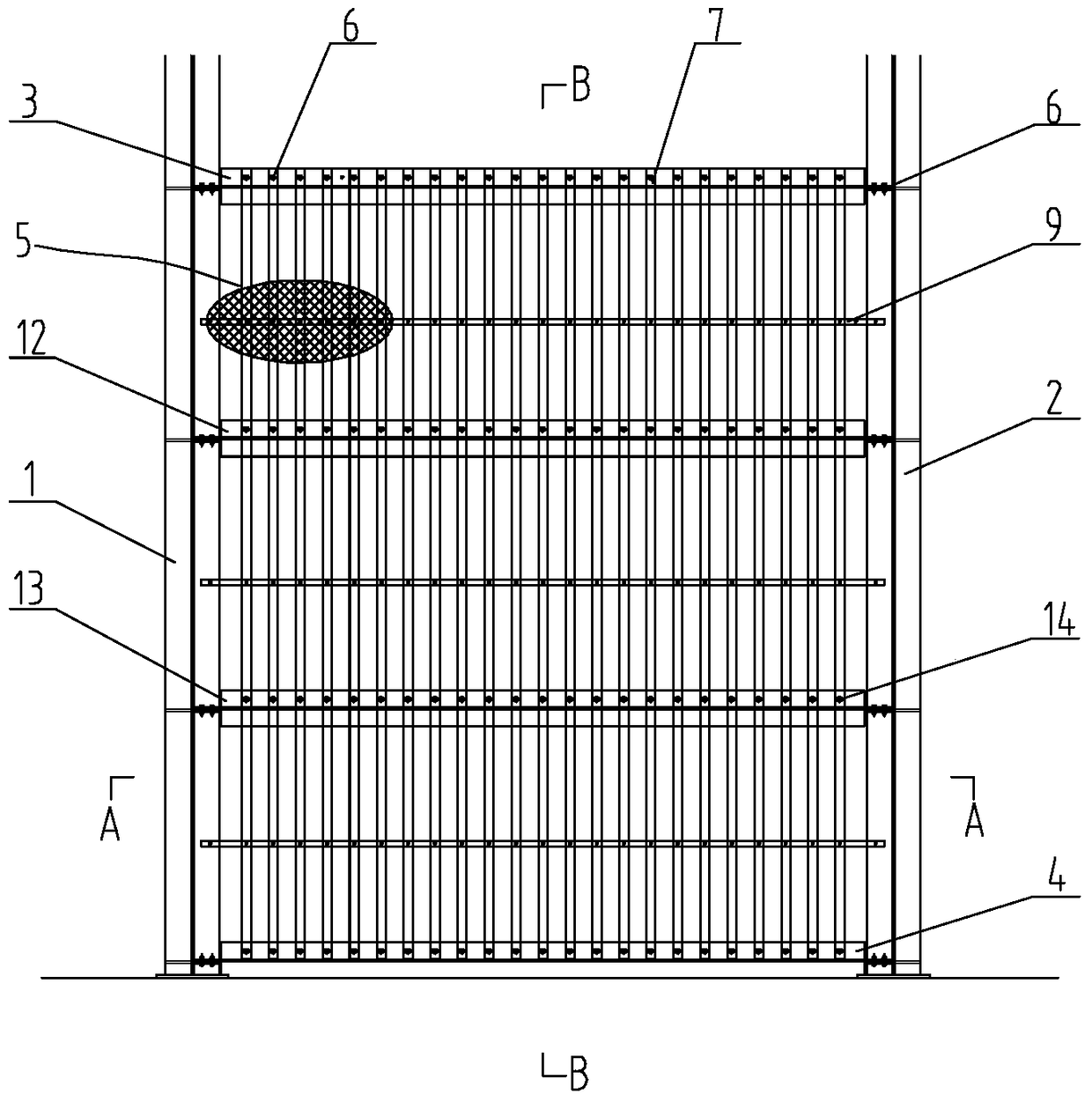

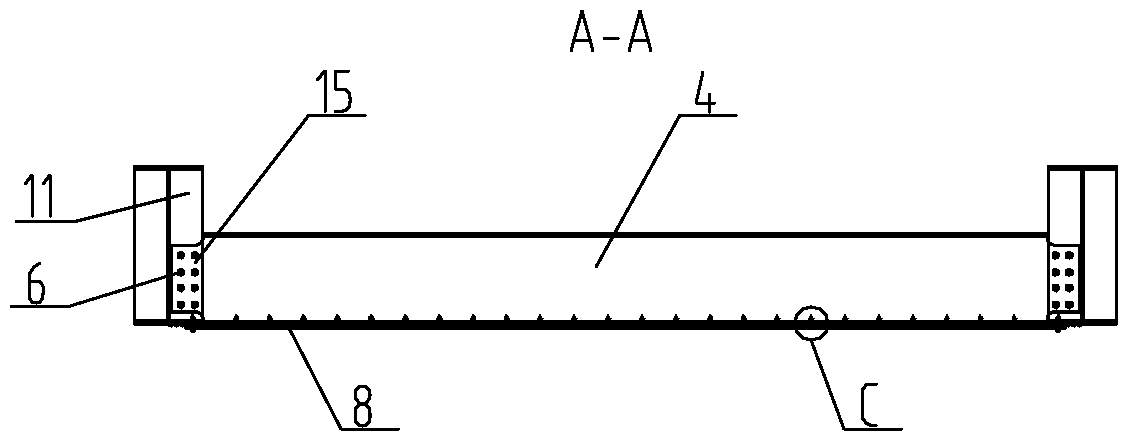

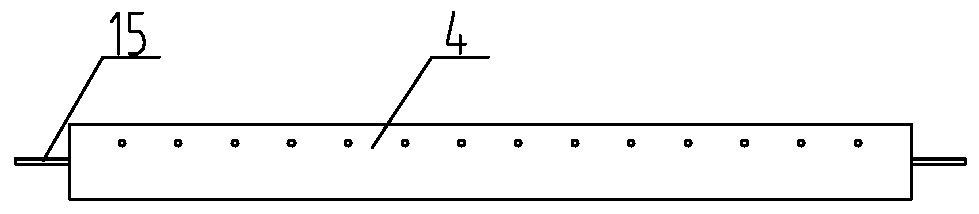

[0034] combine figure 1 As shown, the grain retaining structure disclosed in this embodiment for an integrated steel structure bulk bungalow warehouse includes a first steel column 1 and a second steel column 2, and both the first steel column 1 and the second steel column 2 are vertical Setting; also include the first force-transmission steel beam 3 and the second force-transmission steel beam 4 parallel to each other, one end of the first force-transmission steel beam 3 is vertically fixedly connected with the first steel column 1 by bolt 6, the first force-transmission The other end of the steel beam 3 is also vertically fixedly connected to the second steel column 2 through bolts 6; Preferably, the second force-transmitting steel beam 4 is arranged at the bottom ends of the first steel column 1 and the second steel column 2, and one end of the second force-transmitting steel beam 4 is perpendicular to the first steel column 1 through the bolt 6 Fixedly connected, the othe...

Embodiment 2

[0043] combine Figure 8 to Figure 10 As shown, the difference between this embodiment and the first embodiment is that the force-bearing member 5 is composed of multiple galvanized steel sheets 10, and the joints of the multiple galvanized steel sheets 10 are connected by bolts 6. At the same time, each galvanized steel sheet 10 is It is fixedly connected with the first force-transmitting steel beam 3, the second force-transmitting steel beam 4, the third force-transmitting steel beam 12, and the fourth force-transmitting steel beam 13 through bolts 6, and multiple galvanized steel plates 10 have the function of retaining grain. The lateral force generated by the grain in the bungalow is directly transmitted to the first force-transmitting steel beam 3, the second force-transmitting steel beam 4, the third force-transmitting steel beam 12, and the fourth force-transmitting steel beam through a plurality of galvanized steel plates 10. 13. Finally, the force is transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com