Cage ladder

A cage ladder and ladder technology, which is applied in the field of cage ladders for pumping units, can solve problems such as endangering the lives of workers, wear and tear of parts, and difficulty in ensuring the safety of workers, and achieve reasonable structural design, practical and convenient installation, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects of the device easy to understand, the following will be described in detail in combination with specific diagrams.

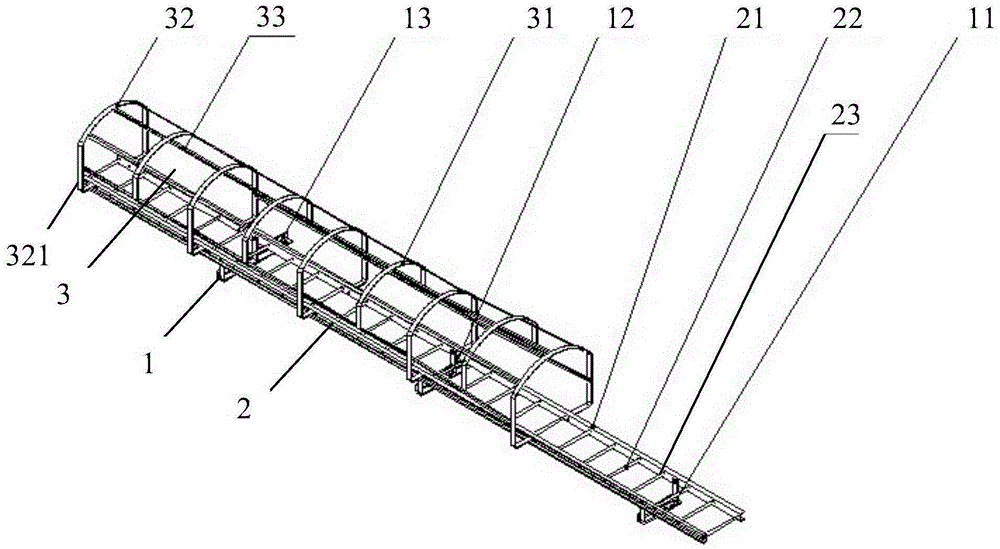

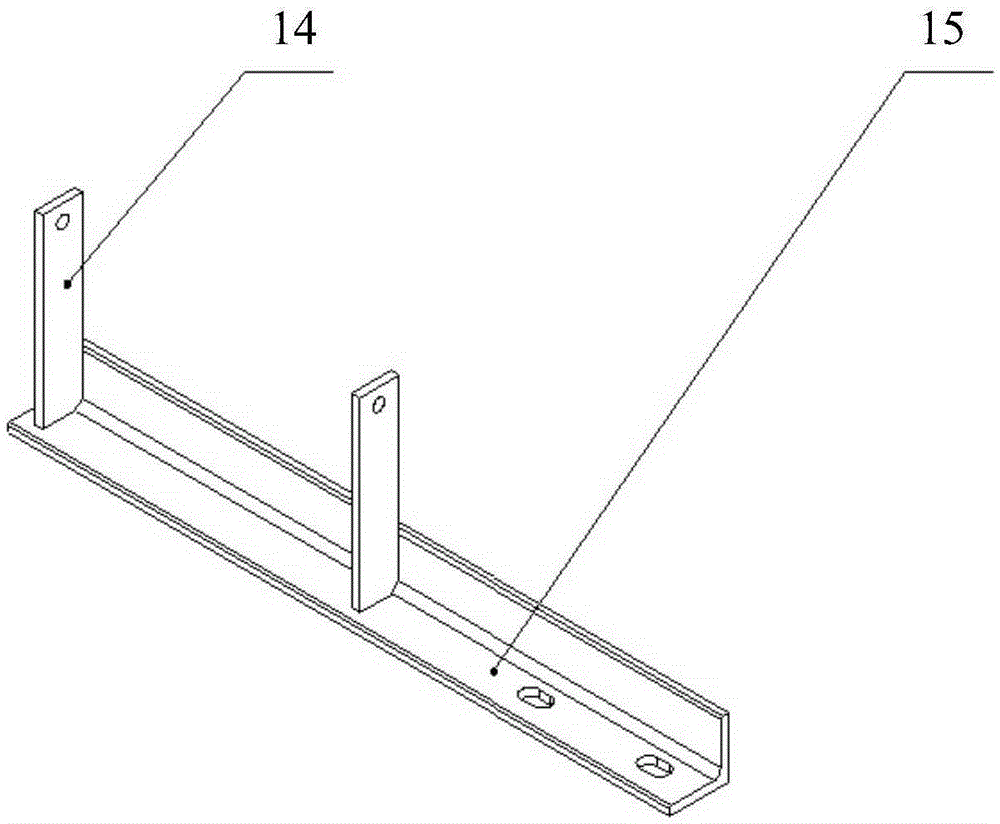

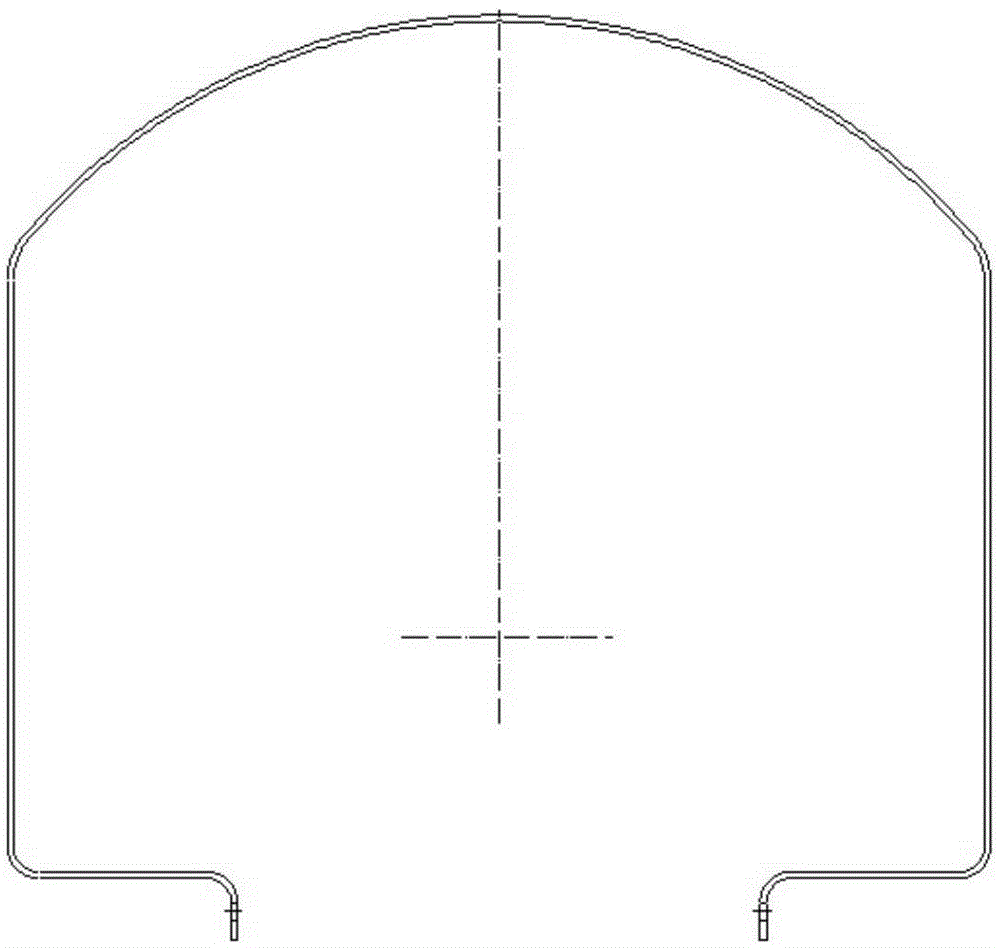

[0025] Such as figure 1 As shown, the cage ladder involved in an embodiment of the present invention includes a bracket 1 , a ladder 2 and a protective cover 3 . The ladder 2 is fixed by the bracket 1 for maintenance personnel to climb, and the protective cover 3 is fastened and installed on one side of the climbing surface of the ladder 2 to form a crawling passage to protect the operators.

[0026] This embodiment can make the cage ladder completely independent through the above structure, so as to be installed in any place that needs to be used. When installing, the bracket 1 and / or the protective cover 3 can form a fixed relationship with the fixed point, so that the cage ladder can be used more secure. The protective cover can provide the user with a docking or supporting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com