Development method of untabulated reservoir in extra-high water-cut period

A technology of ultra-high water cut period and development method, applied in the field of oil and gas field development engineering, can solve problems such as poor connectivity, poor development effect, and immature deep profile control technology, and achieve the effect of improving oil recovery and resolving conflicts between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for developing a long wall off-surface reservoir in an ultra-high water-cut period. The method specifically includes the following steps:

[0046] 1. Based on the Changyuan geology, production and coring well monitoring data, clarify the geological development characteristics of the Changyuan outer reservoirs, the production status of the Changyuan outer reservoirs, and the water washing characteristics of the Changyuan outer reservoirs;

[0047] Among them, the collection of Daqing Changyuan geological, production and coring well monitoring data includes:

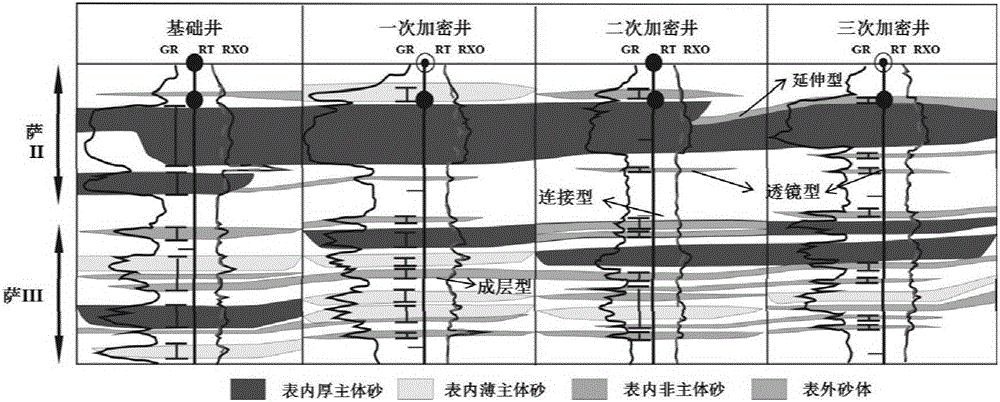

[0048] Geological data: sedimentary facies map, well-connected profile;

[0049] Production data: production dynamic data (oil production, water production, gas production, oil production intensity, water cut) of a single well in the tertiary infill test area and a single well in the independent development test area;

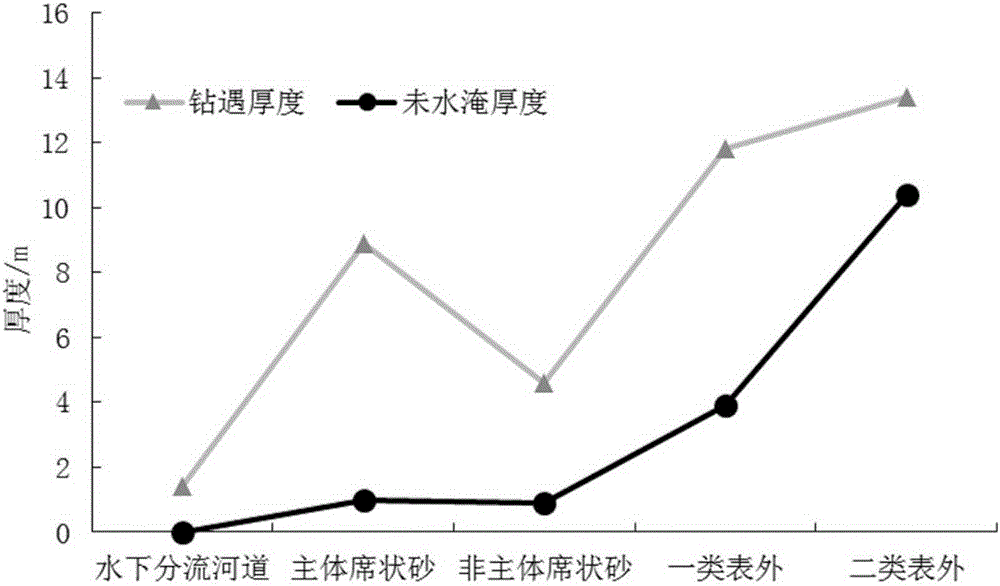

[0050] Coring well monitoring data: statistical data of drille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com