Double-disc wedge gate valve adopting composite spring connection

A composite spring and double ram technology, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of non-interchangeability, achieve convenient on-site operation, reduce installation and operation and maintenance requirements, and avoid over-tightening of the switch or too loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

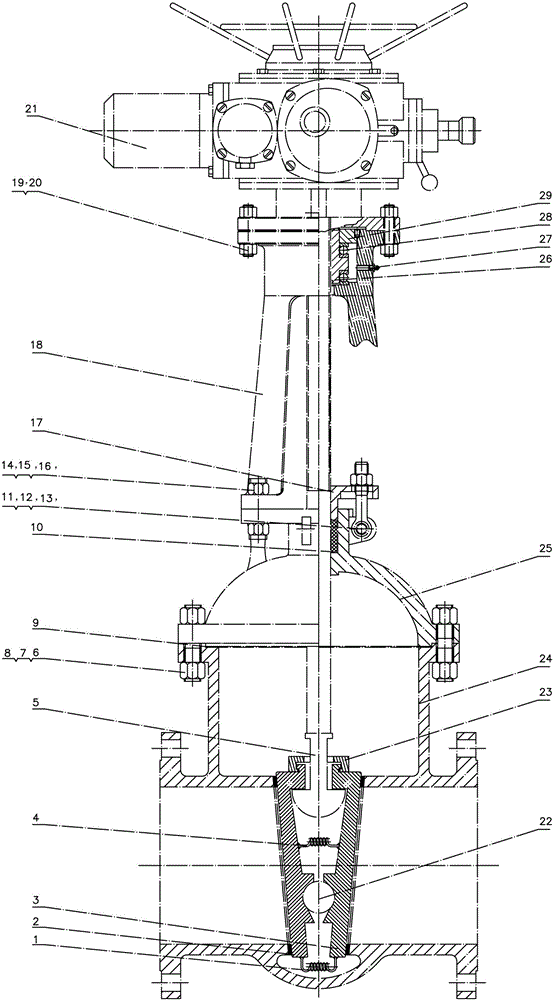

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] see figure 1 , a composite spring-connected wedge-type double-gate gate valve, which includes a valve body 24, a gate plate, a valve stem 5, a valve cover 25, packing 10, a packing gland 17, a bracket 18, a valve stem T-nut 26, and a bearing 28 , bearing gland 29 and all connected fasteners 6-8, 11-16, 19-20, the specific structure and assembly method of each fastening assembly are the prior art, the upper end of the valve stem and the upper sealing box of the valve cover The sealing packing in the middle fits and protrudes out of the packing gland, cooperates with the T-nut on the bracket, connects through thread transmission, and then connects with the actuator 21. The outer circle of the T-nut is closely matched with the thrust bearing. It is characterized in that: The gate is a double gate, which includes a left gate 2 and a right gate 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com